Activated oxygen carbon for enhancing removal efficiency of Fenton-like reaction and preparation and use method thereof

A Fenton reaction and active oxygen technology, applied in chemical instruments and methods, oxidation treatment of sludge, oxidized water/sewage treatment, etc., can solve the problem of reducing the utilization efficiency of hydrogen peroxide, low contribution of Fenton oxidation reaction, low utilization efficiency of oxidants, etc. problem, to achieve the effect of high active oxygen utilization efficiency and pollutant removal efficiency, accelerated Fenton-like reaction rate, and wide application range of the reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the activated oxygen carbon for enhancing the removal efficiency of the Fenton-like reaction comprises the following steps:

[0045] S1: add water and hydroxide to the biochar, and stir to obtain a suspension;

[0046] S2: in the suspension, add silicate and hydrogen peroxide, and stir to react;

[0047] S3: After the reaction, the solid is separated, washed and dried to obtain the activated oxygen carbon with enhanced Fenton-like reaction removal efficiency.

[0048] Preferably, the shape of the biochar is powder or granular.

[0049] Preferably, in step S1, the quality of the water is 5-100 times that of the biochar.

[0050] Preferably, in step S1, the hydroxide is calcium or magnesium hydroxide, and the quality of the hydroxide is 0.5 to 5 times that of the biochar.

[0051] Preferably, in step S2, the mass concentration of hydrogen peroxide is 30%, and the molar ratio of hydrogen peroxide to hydroxide is 1-3:1.

[0052] Preferably, in st...

Embodiment 1

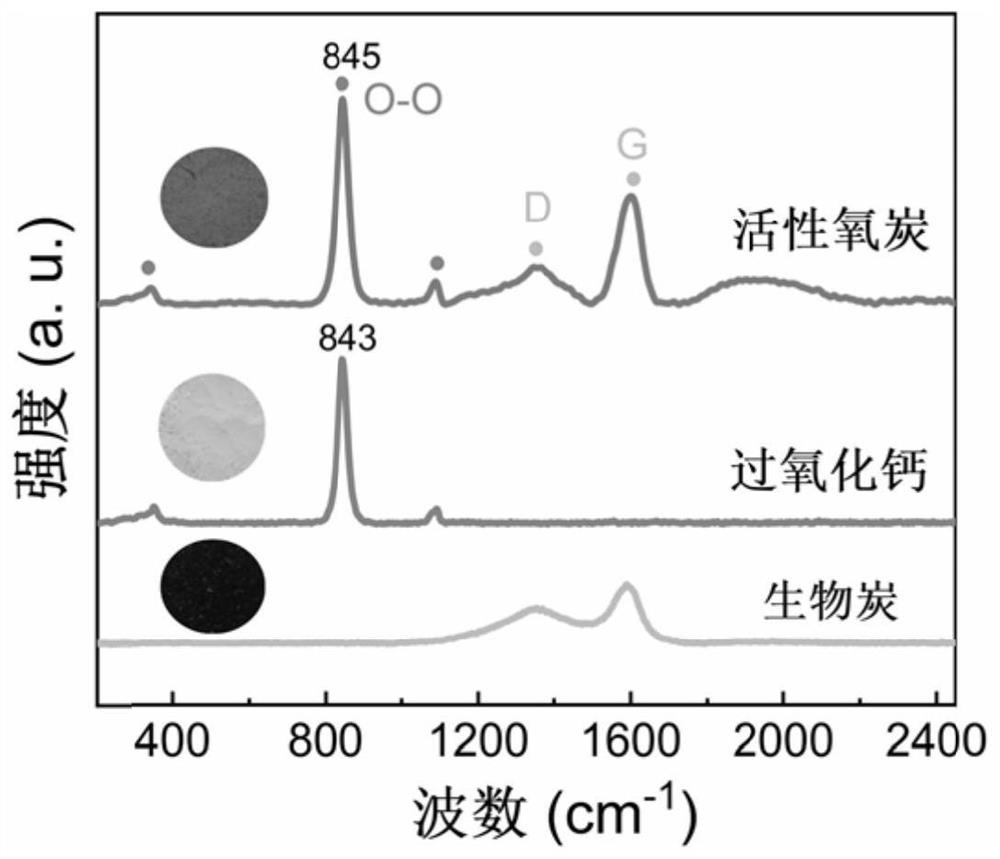

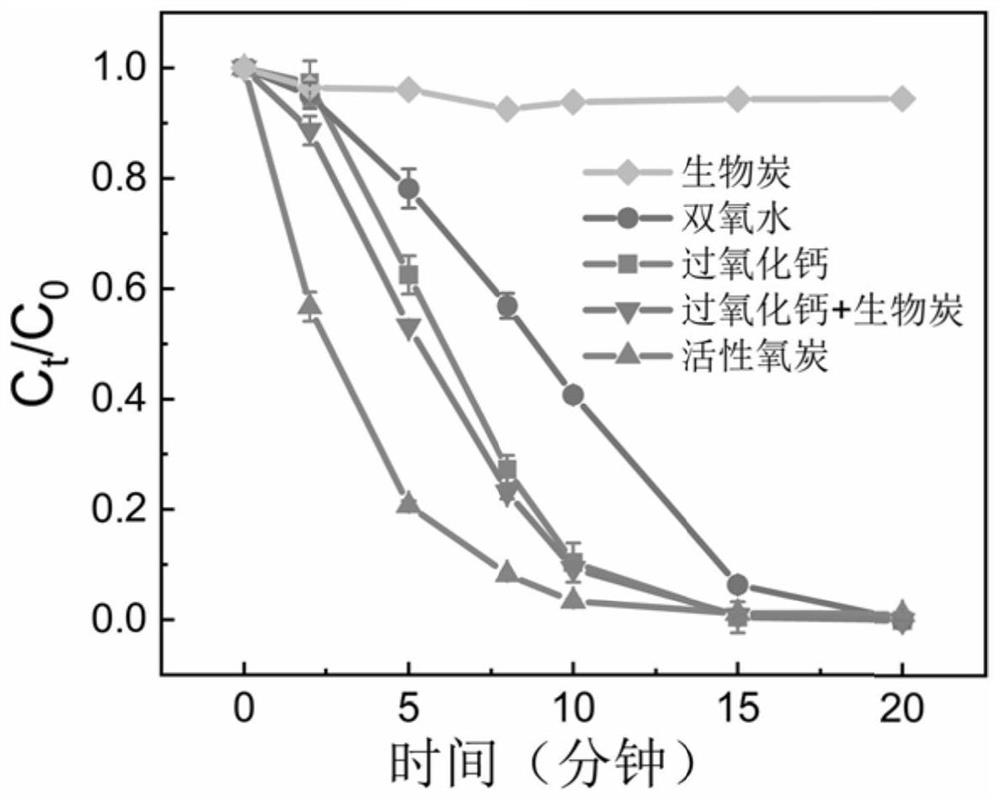

[0067] In 1.2 grams of powdered biochar, add 7 grams of water and 2.5 grams of calcium hydroxide, and stir to obtain a suspension; to the above suspension, successively add 0.05 grams of calcium silicate and 4.5 ml of hydrogen peroxide with a mass concentration of 30% , stirred and reacted at 40 degrees for 1 hour; the solid powder in the suspension was separated by filtration, washed with absolute ethanol, and dried in a blast drying oven at 30 ° C for 12 hours to finally synthesize activated oxygen carbon, in which biochar : calcium peroxide: calcium silicate mass ratio of 1:2:0.02. The Raman spectra and digital photos of the synthesized activated oxygen carbon are as follows figure 1 shown, in which the Raman absorption peak of the peroxy bond is from 843 cm -1 Move right to 845cm -1 , indicating that there is a strong bonding interaction between peroxide and biochar.

[0068] The activated oxygen carbon is used for oxidative degradation of antibiotics in water, wherein ...

Embodiment 2

[0072] In 1.2 grams of powdered biochar, add 6 grams of water and 0.6 grams of calcium hydroxide, and stir to obtain a suspension; in the above suspension, successively add 0.025 grams of calcium silicate and 0.85 ml of hydrogen peroxide with a mass concentration of 30% , stirred and reacted at 10 degrees for 0.5 hours; the solid powder in the suspension was separated by filtration, washed with anhydrous ethanol, and dried in a blast drying oven at 30 ° C for 12 hours to finally synthesize activated oxygen carbon, among which biochar : calcium peroxide: calcium silicate mass ratio of 1:0.5:0.01.

[0073] The activated oxygen carbon is used for oxidative degradation of antibiotics in water, wherein the molar ratio of activated oxygen carbon / ferric chloride is 1:0.1, the molar ratio of ferric chloride and succinic acid is 1:0.5, and the mass ratio of activated oxygen carbon: water is 0.01%, After 20 minutes of reaction, sulfamethoxazole was completely decomposed, and the removal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com