Flatness and roughness detection recorder and detection analysis method

A technology of roughness and flatness, which is used in the field of flatness and roughness detection recorders and detection and analysis, which can solve problems such as low work efficiency, spending a lot of time, and inability to perform detection at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

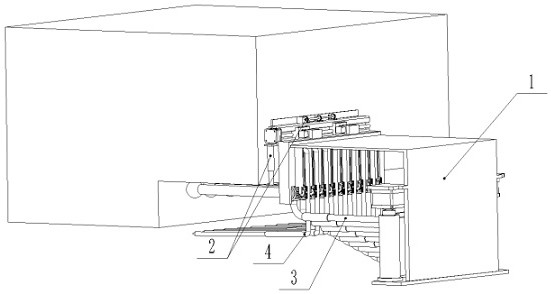

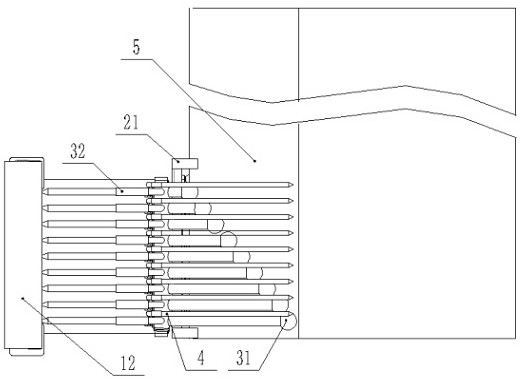

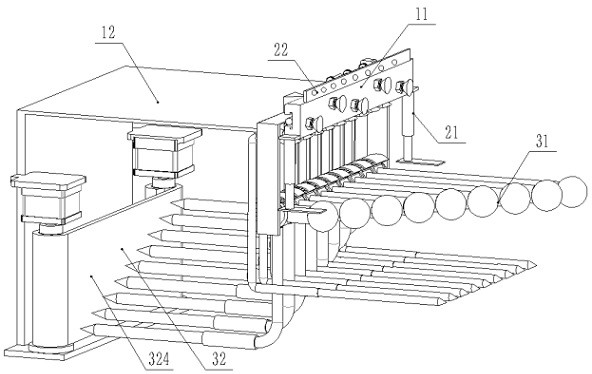

[0050] see Figure 1 to Figure 10 , this embodiment is used to detect the flatness and roughness of one of the sides of the larger width groove provided on the workpiece, specifically: a flatness and roughness detection recorder, including a mounting frame 1, a reference plane alignment device 2. The plane 5 to be measured, in this embodiment, the outer adjacent surface of the plane 5 to be measured is used as the installation datum plane, and the mounting frame 1 includes: a datum plane mounting frame 11 and a connecting frame 12, and the datum plane mounting frame 11 is fixed on the mounting datum surface and is connected with the connecting frame 12 in rotation; the reference plane aligning device 2 includes: a parallel aligning device 21 and a vertical aligning device 22; The alignment device 22 is installed on the top of the datum mounting frame 11; the plane measurement recording mechanism 3 is installed below the connecting frame 12, which includes: a measuring device 3...

Embodiment 2

[0068] Such as Figure 11 As shown, this embodiment is used to detect the flatness and roughness of one of the sides of the groove with a smaller width on the workpiece, specifically: the marking telescopic pen end 4022 in the U-shaped marking assembly 402 is contacted with the detection workpiece groove Both sides are on the same plane reference plane, and other structural principles are the same as above, and will not be repeated here.

[0069] The detection and analysis method of the flatness and roughness detection recorder of the present invention is specifically as follows:

[0070] The first step, on-site inspection:

[0071] The flatness and roughness detection recorder is first fixed on the adjacent surface (reference plane) of the plane 5 to be tested by fixing the telescopic suction cup 114, and the parallel test plate 212 is controlled to fit the plane 5 to be tested by rotating the telescopic cylinder 211 in the parallel alignment device 21 To detect whether the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com