Automatic corrugated carton production method, system and device and storage medium

An automatic production method and corrugated box technology, applied in the direction of manufacturing computing systems, instruments, data processing applications, etc., can solve problems such as long debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

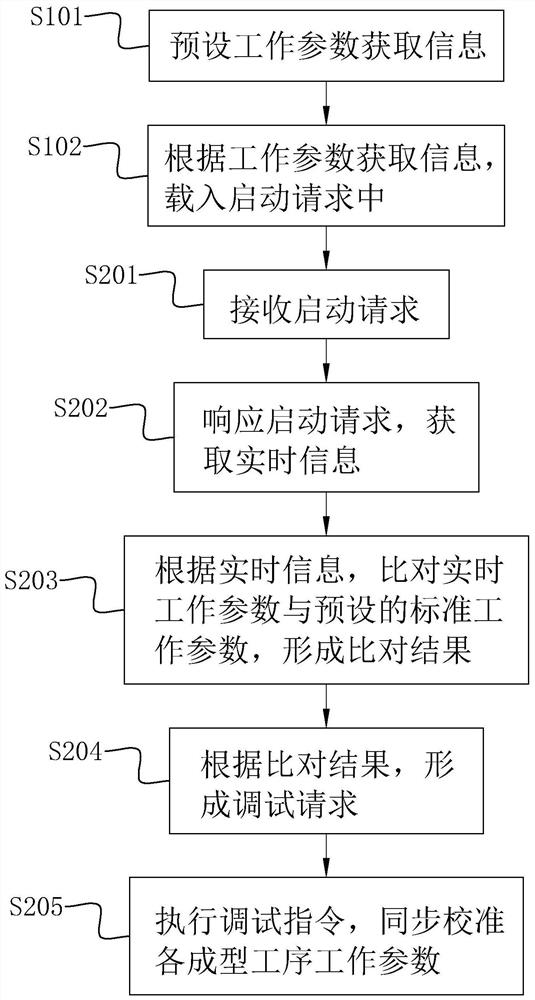

[0061] The following is attached Figure 1-4 The application is described in further detail.

[0062] The embodiment of the present application discloses an automatic production method for corrugated cartons. refer to figure 1 , the automatic production method of corrugated box includes:

[0063] S101, obtaining information on preset working parameters.

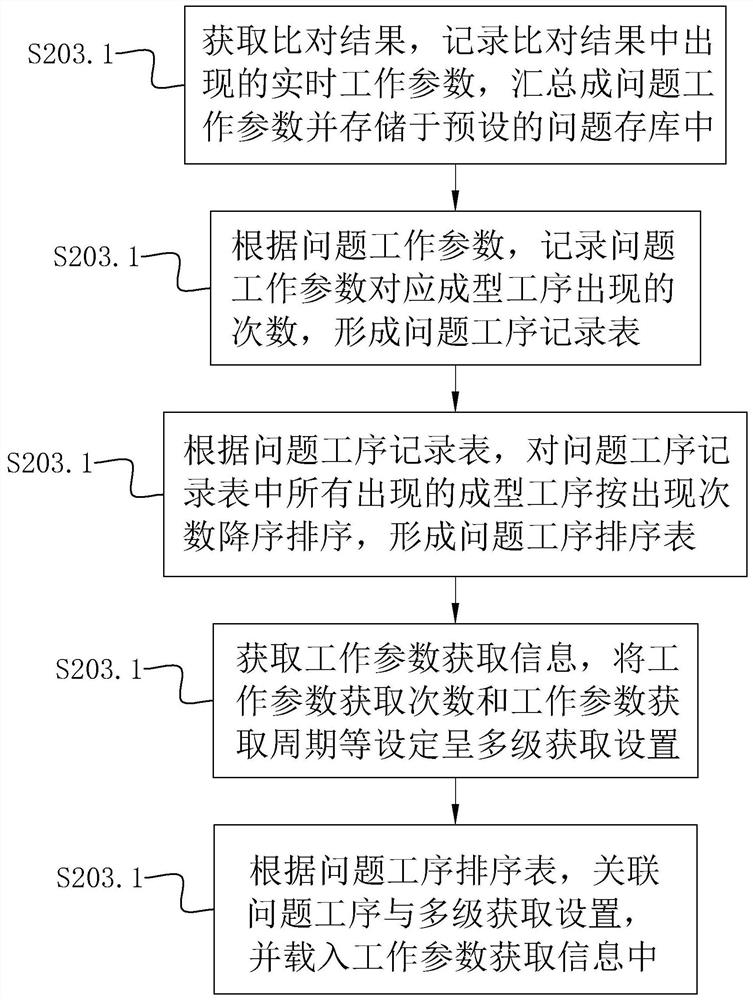

[0064] Wherein, the working parameter acquisition information includes the number of working parameter acquisitions, the working parameter acquisition period, and the like. Specifically, the production line is equipped with input terminals, which include input devices such as mobile phones, tablet computers, and touch screens. Through the input terminals, the staff completes the setting of the number of times and cycle of acquisition of working parameters for each molding process. . For example, set the number of acquisitions of the working parameters of the slotting process to 2 times and the acquisition cycle to 10 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com