Camera module and electronic equipment

A technology of camera module and lens assembly, which is applied in branch equipment, television, electrical components, etc., and can solve the problems of reducing the height of the camera module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

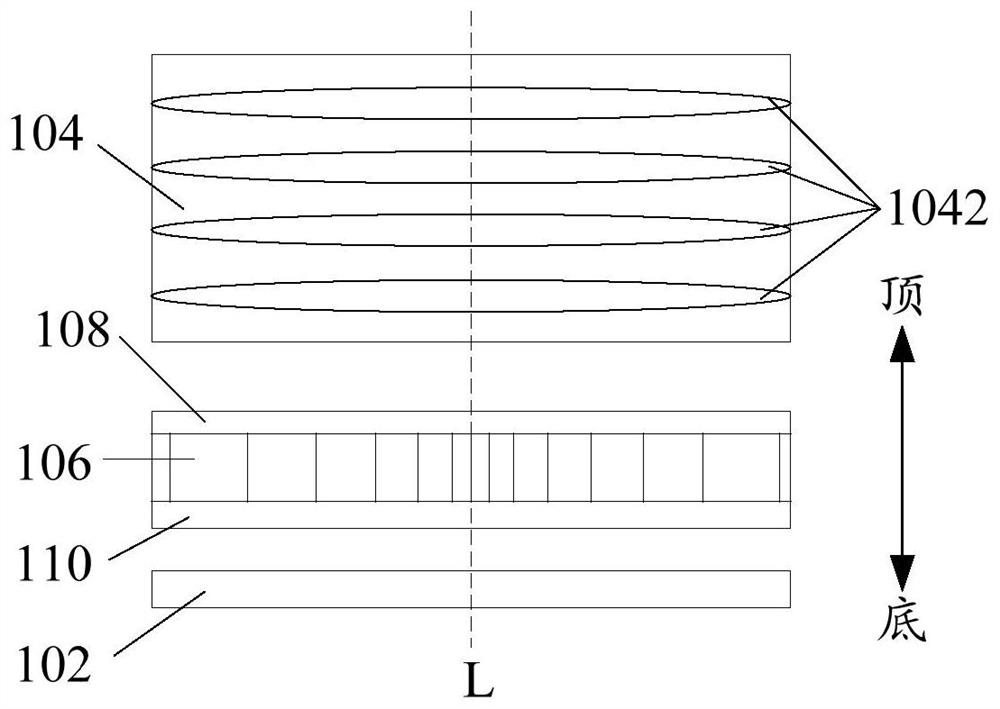

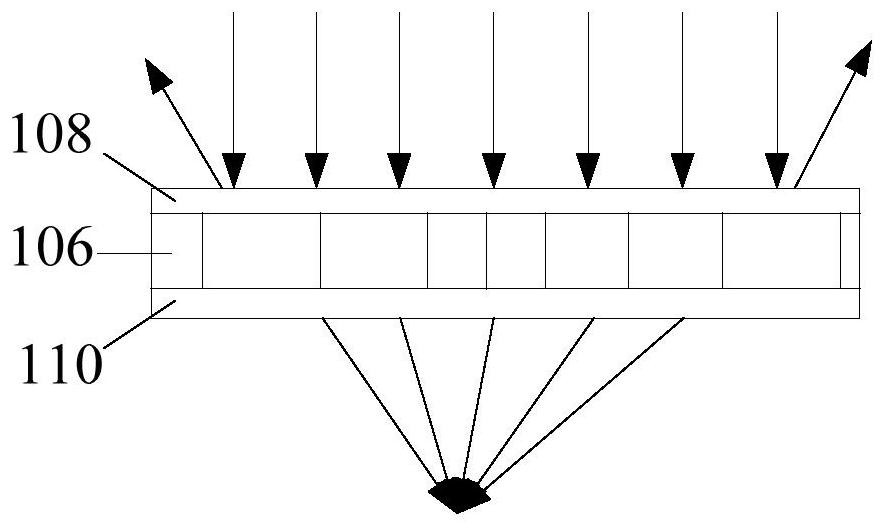

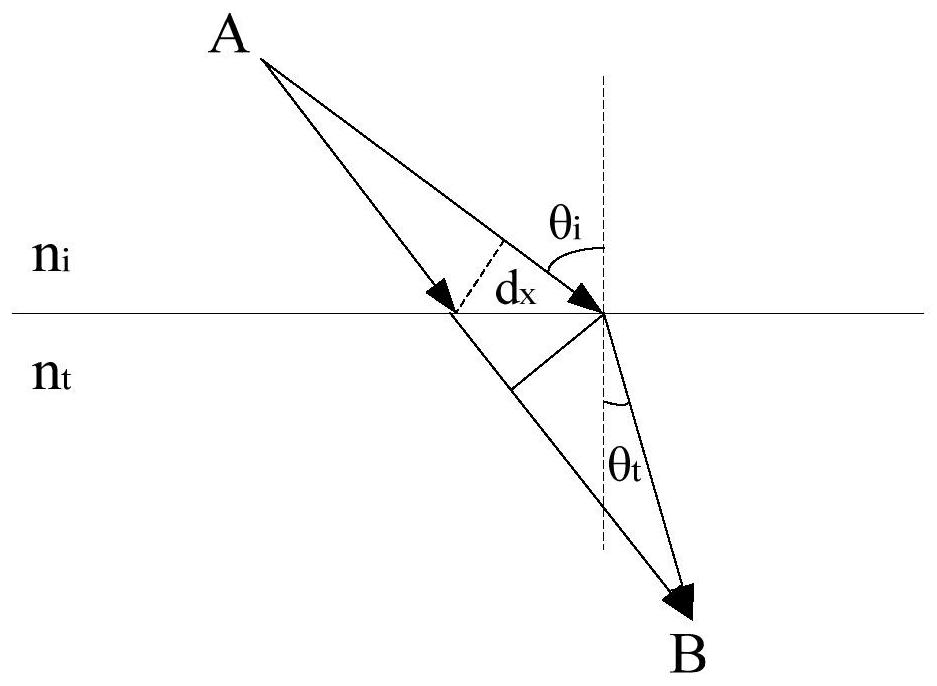

[0063] Specific embodiment one: as Figure 5 As shown, the refractive index distribution of the carrier 106 may vary along the optical axis L, and the darker the color, the greater the refractive index. Using the microelement method, the carrier 106 is sliced, and the division accuracy of the slice is higher ( Figure 5 N in the middle corresponds to the number of slices in the L direction of the optical axis. The larger N is, the smaller the calculation error is. In practice, it can be considered according to specific needs. For example, the optical path change of each micro-element can be set as one percent of the center wavelength, thereby setting a specific N value.

[0064] Typical conic-type refractive index profile: where z is the optical axis, n 0 is the refractive index at z=0, and a is the distribution coefficient. The analytical solution of the corresponding path is:

[0065]

[0066]

[0067] where p 0 , l 0 、m 0 is the direction cosine of the initia...

specific Embodiment 2

[0068] Specific embodiment two: as Figure 6 As shown, in a plane perpendicular to the optical axis L, the refractive index of the carrier 106 gradually changes around the optical axis L, and the darker the color, the larger the refractive index.

[0069] The index of refraction is consistent with the shade of the color, throughout the text. At this time, the micro-element slice will be parallel to the optical axis L, and the slice precision is similar to that in method 1, and the optical path can be controlled within one hundredth of a wavelength ( Figure 6 N in the middle corresponds to the number of slices in the radial direction of the optical axis L, the larger N is, the smaller the calculation error is, and it can be considered according to specific needs, for example, the optical path change of each micro-element can be set to one percent Center wavelength, so as to set a specific N value. For the basic quadratic index profile: Relevant parameters are consistent wi...

specific Embodiment 3

[0073] Specific embodiment three: as Figure 7 As shown, the refractive index distribution of the carrier 106 changes along the optical axis L, and in a plane perpendicular to the optical axis L, the refractive index of the carrier 106 also gradually changes around the center of the optical axis L, and the darker the color The greater the refractive index. In this case, binary slicing is required.

[0074] Figure 7 Among them, M and N respectively correspond to the number of slices in the direction of the optical axis L and the radial direction, and it is also necessary to ensure an optical path difference with an accuracy of one hundredth of a wavelength. This two-dimensional change mode makes it have more degrees of freedom in light manipulation, and is more helpful to the design optimization of the bearing member 106 .

[0075] The above three specific implementation methods all deal with the carrier 106 , so that the number of lenses 1042 in the lens assembly 104 can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com