Method and device for pulse vibration electrochemical grinding of end face of rotary part

A technology for electrochemical grinding and rotating parts, which is applied in metal processing equipment, manufacturing tools, electrolytic components, etc., can solve the problems of difficult process adjustment, complex structure of composite tools, and difficult manufacturing, and achieves simple tool structure design and improved processing. Locality, stray corrosion suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings.

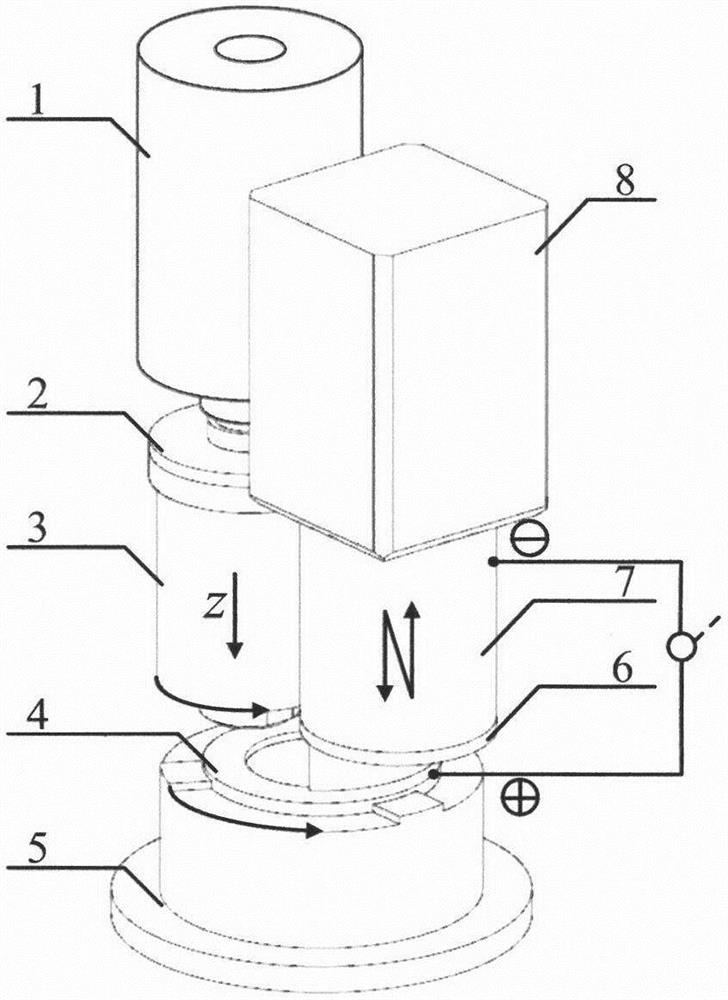

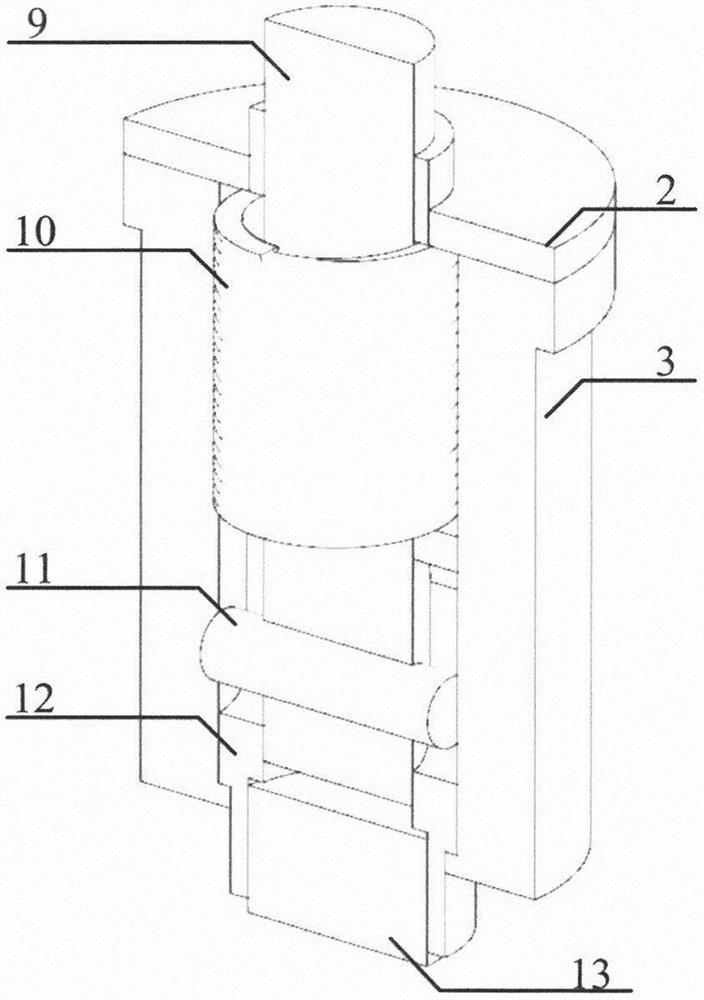

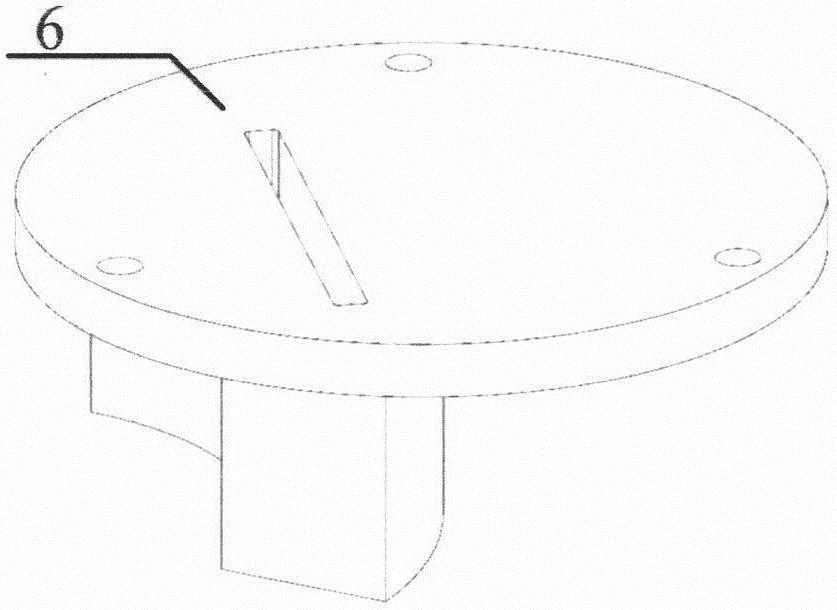

[0017] like figure 1 Shown is the pulse vibration electrochemical grinding processing device for the end face of the rotary part, such as figure 2 Abrasive hold-down device shown. The pulse vibration electrochemical grinding processing device includes a mechanical grinding device, a pulse vibration electrochemical processing device and a rotary part rotating device, wherein the mechanical grinding device includes an electric spindle 1, a pressure plate 2, a positioning sleeve 3, a rotating mandrel 9, and a compression spring 10. , cylindrical pin 11, moving shaft sleeve 12, grinding tool 13, cylindrical grinding tool 13 is fixedly connected to moving shaft sleeve 12 through set screws, and the side wall of moving shaft sleeve 12 is provided with a symmetrical waist-shaped hole, and there is a gap with the positioning sleeve 3 Matching, the top of the positioning sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com