A flame-retardant thermoplastic polyurethane composite material

A technology of thermoplastic polyurethane and composite materials, which is applied in the field of flame retardant materials, can solve the problems of low flame retardant efficiency of composite materials, reduced heat release and smoke release, and achieves reduced heat release rate, good flame retardant effect, and reduced Effect of total heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A flame retardant thermoplastic polyurethane composite, prepared according to the following steps:

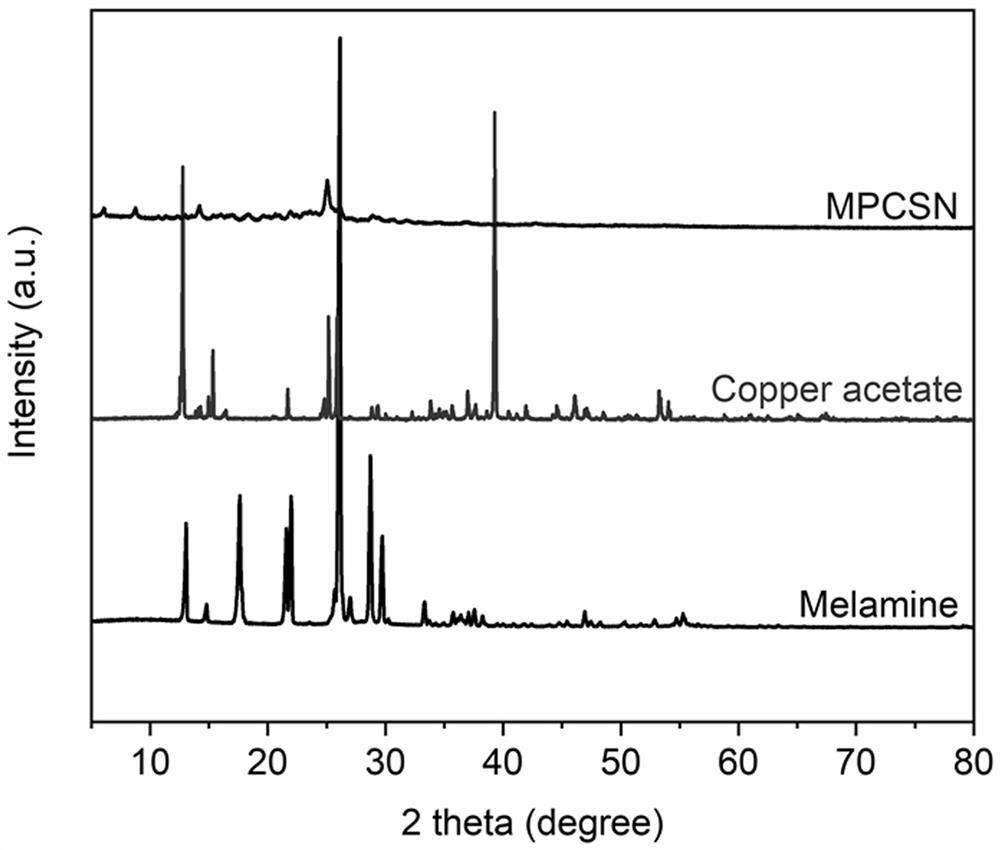

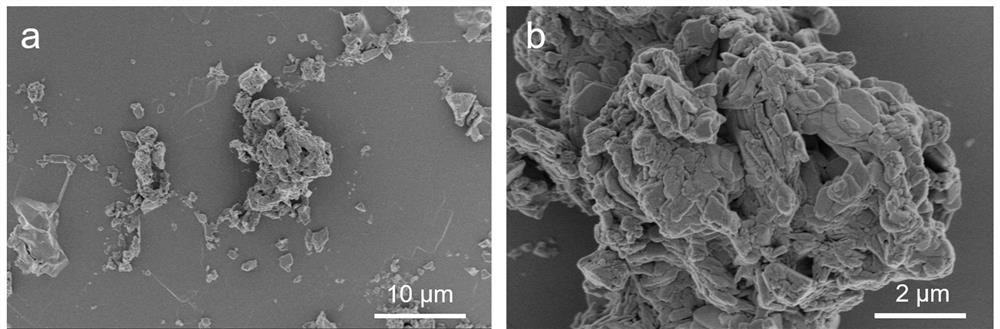

[0031] (1) 1.76 parts of copper with copper, 9 parts of melamine and 100 ml of deionized water were taken in 250 ml of three neck round bottom flasks, and the mechanical agitator was installed, and the mixture was stirred at room temperature for 30 minutes.

[0032] (2) EtOAc EtOAc EtOAc EtOAc EtOAc.

[0033] (3) The mixture was centrifuged once, and the deionized water was washed 3 times, no water ethanol was washed once, and the dried over 60 degrees Celsius was dried for 24 hours to obtain a "melamine-phytic acid-copper ion" super molecular network flame retardant.

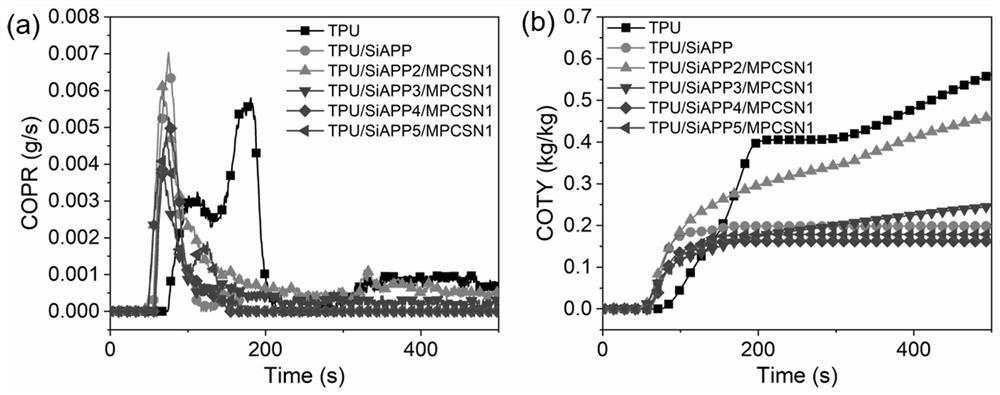

[0034] (4) Take 54 parts of thermoplastic polyurethane in double roller mill, which is completely melted at 185 degrees Celsius, add 4 parts of silicon-wrapped polyphosphate, 2 parts "melamine-phytic acid-copper ion" super molecular network flame retardant Melting is mixed.

[0035] (5) Place the sample after...

Embodiment 2

[0037] A flame retardant thermoplastic polyurethane composite, prepared according to the following steps:

[0038] (1) 1.76 parts of copper with copper, 9 parts of melamine and 100 ml of deionized water were taken in 250 ml of three neck round bottom flasks, and the mechanical agitator was installed, and the mixture was stirred at room temperature for 30 minutes.

[0039] (2) EtOAc EtOAc EtOAc EtOAc EtOAc.

[0040] (3) The mixture was centrifuged once, and the deionized water was washed 3 times, no water ethanol was washed once, and the dried over 60 degrees Celsius was dried for 24 hours to obtain a "melamine-phytic acid-copper ion" super molecular network flame retardant.

[0041] (4) Take 54 parts of thermoplastic polyurethane in double roller mill, which makes it completely melted at 185 degrees Celsius, add 4.5 parts of silicon-wrapped polyphosphate, 1.5 parts "melamine-phytic acid-copper ion" super molecular network flame retardant Melting is mixed.

[0042] (5) Place the sa...

Embodiment 3

[0044] A flame retardant thermoplastic polyurethane composite, prepared according to the following steps:

[0045] (1) 1.76 parts of copper with copper, 9 parts of melamine and 100 ml of deionized water were taken in 250 ml of three neck round bottom flasks, and the mechanical agitator was installed, and the mixture was stirred at room temperature for 30 minutes.

[0046] (2) EtOAc EtOAc EtOAc EtOAc EtOAc.

[0047] (3) The mixture was centrifuged once, and the deionized water was washed 3 times, no water ethanol was washed once, and the dried over 60 degrees Celsius was dried for 24 hours to obtain a "melamine-phytic acid-copper ion" super molecular network flame retardant.

[0048] (4) Take 54 parts of thermoplastic polyurethane in double roller mill, which makes it completely melted at 185 degrees Celsius, add 4.8 parts silicon wrap copolyphosphate, 1.2 parts "melamine-phytic acid-copper ion" super molecular network flame retardant Melting is mixed.

[0049] (5) Place the sample a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com