Thermoplastic resin composition

A thermoplastic resin and composition technology, applied in the field of modified thermoplastic resin composition and thermoplastic resin composition, can solve the problems of content not exceeding 30%, difficult to popularize and apply in a large range, high cost of copolymer, and improve weld line defects. , low price, safe use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

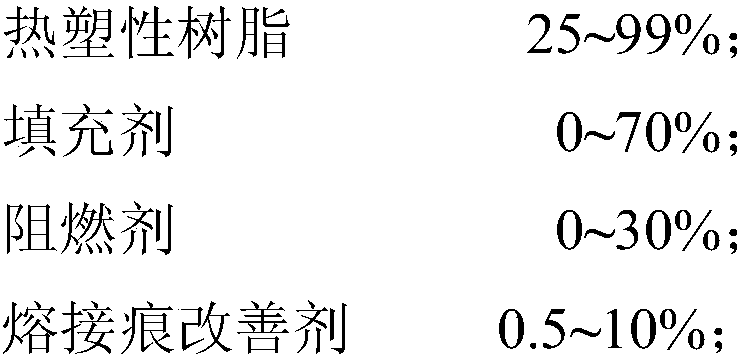

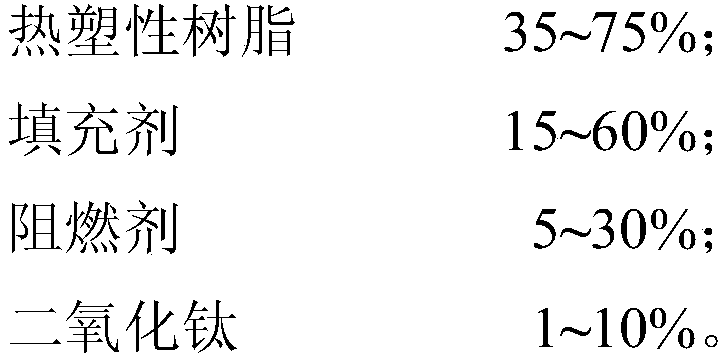

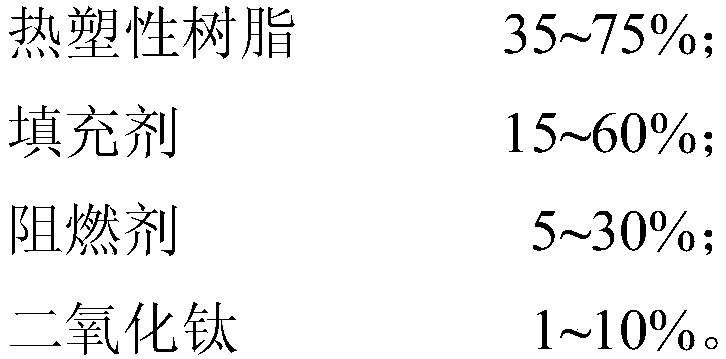

Method used

Image

Examples

Embodiment 1~ Embodiment 13

[0054] According to the material ratio in Table 1, the components of thermoplastic resin, weld line improving agent and other additive materials were mixed uniformly first, and then extruded and granulated by twin-screw extruder. The length-to-diameter ratio of the twin-screw extruder is 40:1, the screw speed is 280r / min, the strands are watered and pelletized. After the particles are dried (usually in a vacuum oven at 80°C for 5-8 hours), the standard specimens corresponding to the test are molded in the injection molding machine, and the performance test is carried out. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com