Tamping coal blending coking method, product thereof and blended coal for coking

A coal blending coking and coking coal technology, applied in the coking oven, petroleum industry, etc., can solve the problems of unbalanced structure and geographical distribution, and achieve the effects of reducing the consumption of coking coal resources, ensuring the quality of coke, and reducing the cost of coal blending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

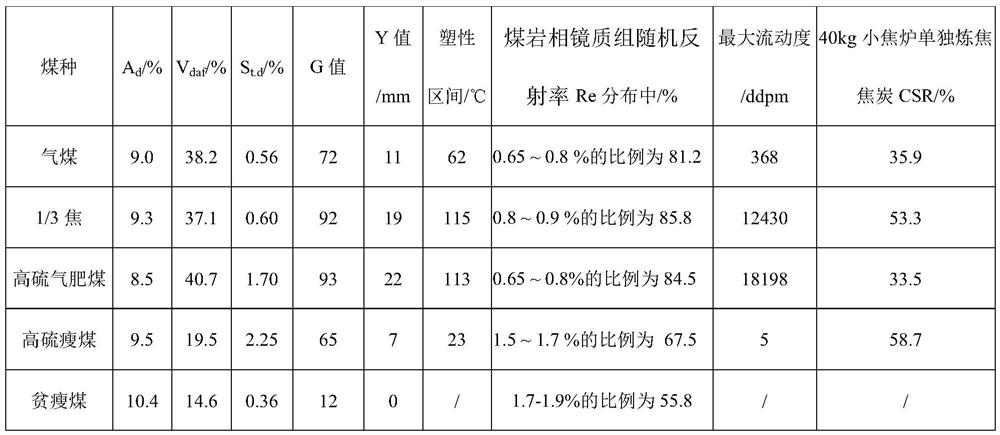

[0067] This embodiment provides a coking method for tamping coal blending, including the step of mixing individual coking coals, and the individual coking coals and their weight percentages are as follows: gas coal 15%, 1 / 3 coking coal 30%, gas fertilizer 10% coal, 15% high-sulfur lean coal, and 30% lean lean coal. The quality indicators of each single coking coal used in Example 1 are listed in the following Table 1.

[0068] Table 1

[0069]

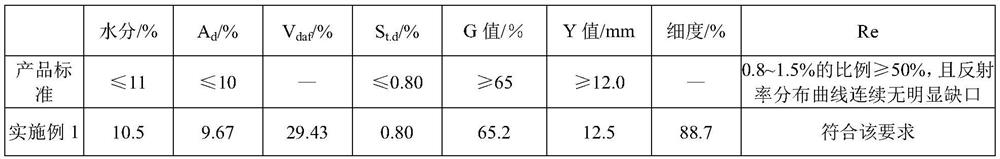

[0070] The gas coal is pre-crushed, and the volume percentage of fineness (less than 3mm) particles after pre-crushing is 87.8%, and then each single coal is mixed according to the above weight percentage, and then put into the pulverizer together to make the coal into the furnace fine The volume percentage of high-density (less than 3mm) particles is 88.7%, and the bulk density is 1.03t / m 3 . The index data of the blended coal prepared are shown in Table 2.

[0071] Table 2

[0072]

[0073] Among them, "—" indicates that th...

Embodiment 2

[0080] This embodiment provides a coking method for tamping coal blending, including the step of mixing individual coking coals, and the individual coking coals and their weight percentages are as follows: gas coal 5%, 1 / 3 coking coal 40%, gas fertilizer Coal 5%, high-sulfur lean coal 10%, lean lean coal 30%, the quality index of each single coking coal used in embodiment 2 is the same as table 1.

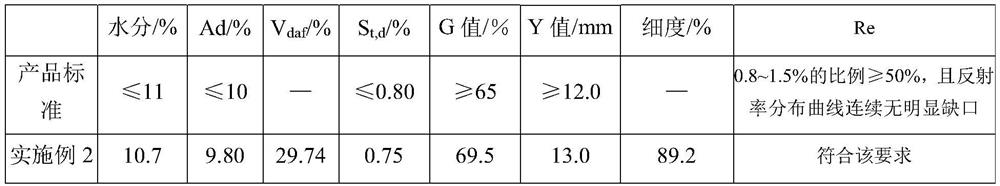

[0081] The gas coal is pre-crushed, and the volume percentage of fineness (less than 3mm) particles after pre-crushing is 87.8%, and then each single coal is mixed according to the above weight percentage, and then put into the pulverizer together to make the coal into the furnace fine The volume percentage of high-density (less than 3mm) particles is 89.2%, and the bulk density is 1.03t / m 3 . The index data of the blended coal prepared are shown in Table 4.

[0082] Table 4

[0083]

[0084] Among them, "—" indicates that there is no requirement for this indicator in the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com