Coal blending method for improving coke quality in coke oven carbonization chamber with width below 500mm

A technology of coke quality and carbonization chamber, which is applied in the field of coal blending to improve the quality of coke in coke ovens with a width of less than 500mm in the carbonization chamber.

Active Publication Date: 2014-11-05

武汉钢铁有限公司

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Song Zikui et al. developed a classification and evaluation method for 1/3 coking coal, coking coal and other coal types (such as the coking coal blending method application number 201010599230.6 involving 1/3 coking coal), and proposed differe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a coal blending method for improving coke quality in an coke oven carbonization chamber with the width below 500mm, and the coal blending method comprises the following steps: 1) identifying the mass percentage of each single coal in blended coal; 2) controlling the ash content in the blended coal to be Ad<10%, the sulfur content to be St,ad < 0.9%, and G value to be 75-78; 3) directly blending coking coal with the fineness of not less than 60% for coking without passing through of a pulverizer; mixing each coking coal with the fineness of less than 60% in the mass percentage determined in the step 1), then passing through the pulverizer, controlling the fineness to be 75% +/-3%; mixing the coking coal passing through the pulverizer and the coking coal which does not pass through the pulverizer, mixing by a belt process, then entering into a coal tower for standby coking. The method, under the premise of ensuring of the coke quality, combines the actual width of the coke oven carbonization chamber to realize the optimal mixing use of different kinds of coal and different coal resources, and greatly reduces the cost of coal blending.

Description

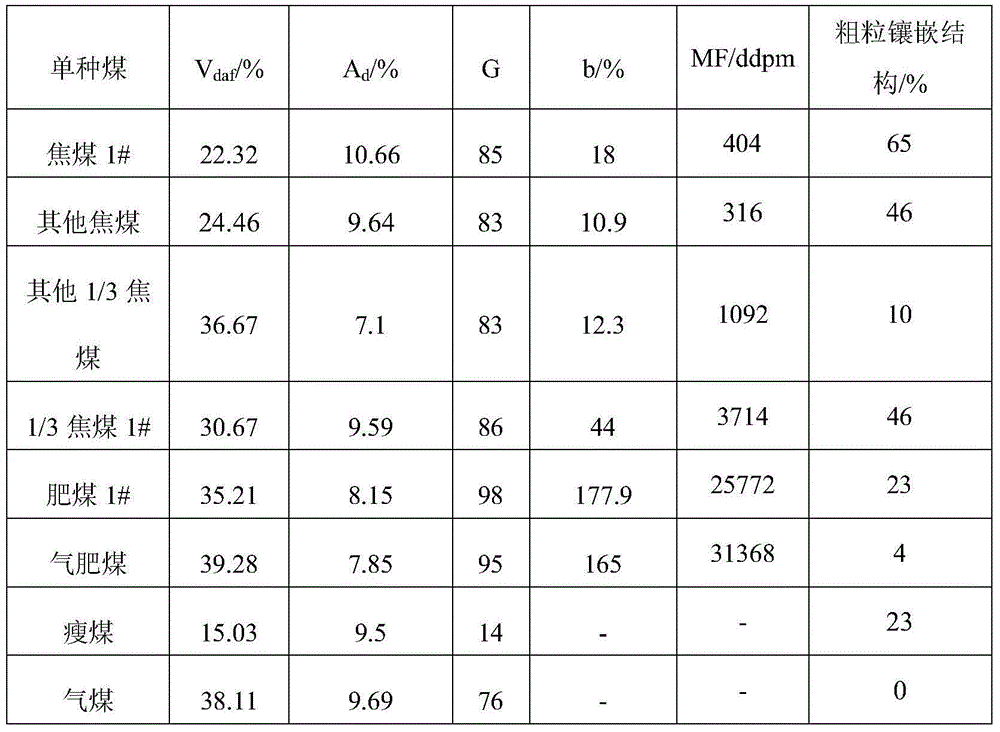

technical field [0001] The invention belongs to the technical field of coking coal blending, and in particular relates to a coal blending method for improving the coke quality of a coke oven in a carbonization chamber with a width of less than 500 mm. Background technique [0002] my country's iron and steel industry continues to develop, and the large-scale blast furnace has promoted the vigorous development of large-volume coke ovens. However, the distribution of coke ovens in my country is still dominated by coke ovens with narrow carbonization chambers below 500mm. The width of the carbonization chamber is different, so that the distance from the heating side to the center of the coke cake is different, and the uniformity of colloid formation and decomposition is different, which ultimately affects the quality of coke. The width of the carbonization chamber is narrowed, the width uniformity of the coke cake is improved, and the fluidity and expansion required for blendi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10B57/04

Inventor 张雪红项茹薛改凤刘睿陈鹏宋子逵鲍俊芳詹立志任玉明王元生

Owner 武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com