A kind of aluminum alloy profile quenching additive and quenching process

A technology of aluminum alloy profiles and additives, applied in the field of quenching fluid, can solve the problems of high toxicity of diisobutyl ketone, blackening of quenching agent, strong irritation, etc., to ensure quality consistency, reduce maintenance times, and excellent flame retardant performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1D

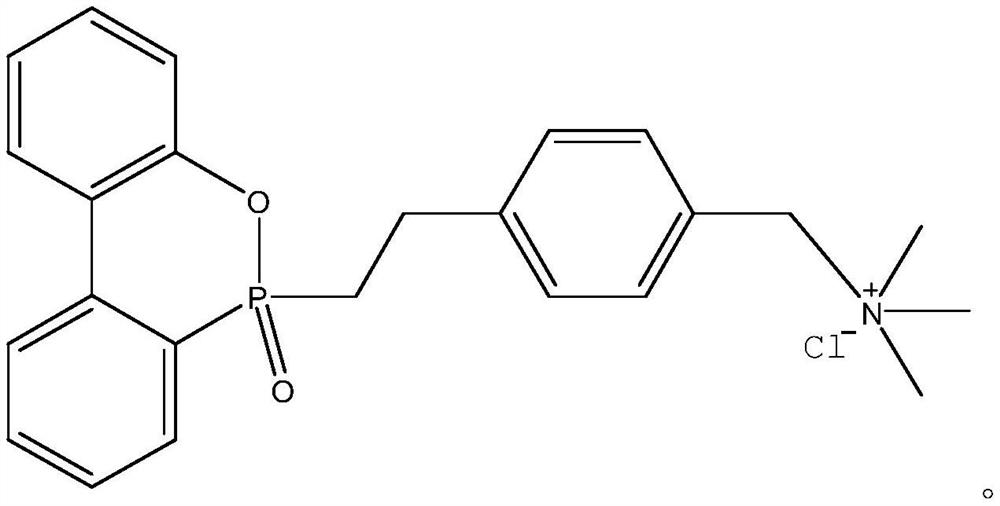

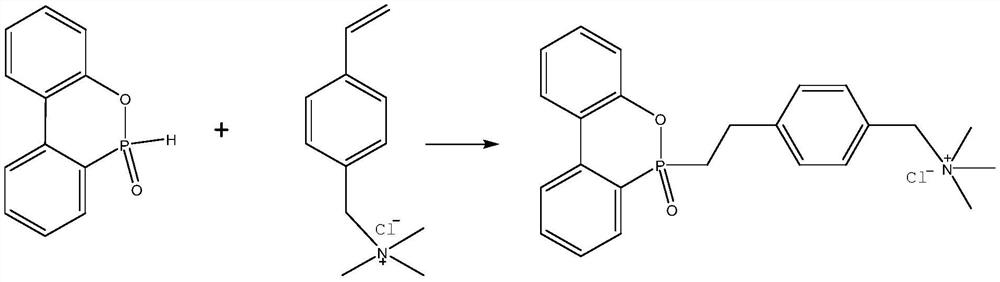

[0022] Example 1 Synthesis of DOPO Derivatives

[0023]

[0024] Add 0.12mol DOPO, 0.1mol N,N,N-trimethyl-p-vinylbenzylammonium chloride (structure above), 1L dichloromethane to the reaction kettle, stir and reflux for 2h, after the reaction is completed, concentrate the reaction liquid, 650 ml of dichloromethane were evaporated, crystallized by cooling, filtered, and dried in vacuo to obtain a white solid with a yield of 98% and a HPLC purity of 99.2%. 1 H-NMR (D-CCl 3 , ppm): 7.42(m, 1H), 7.2~7.3(m, 4H), 7.11(s, 1H), 7.06(m, 2H), 6.98(m, 2H), 6.8~6.9(m, 2H), 5.2 (m, 2H), 3.13 (m, 9H), 2.9 (m, 2H), 1.6 (m, 2H).

Embodiment 2

[0026] Based on 100 parts by weight of the whole quenching agent, 15 parts by weight of PAG stock solution and 85 parts by weight of deionized water were prepared. The use of the quenching liquid in the company's production line: the outlet temperature of the profile is controlled at 550 ℃, and 2 tons of aluminum alloy profiles are processed continuously. The surface of the profile begins to show changes such as bending and streaks, and the quenching liquid turns black and has peculiar smell. Flavor is produced.

Embodiment 3

[0028] Based on 100 parts by weight of the quenching agent as a whole, configure 15 parts by weight of PAG stock solution, 8 parts by weight of quenching additives, and 77 parts by weight of deionized water;

[0029] Wherein, based on 100 parts by weight of the quenching additive, 40 parts by weight of polydimethylsiloxane, 30 parts by weight of benzalkonium chloride, and 30 parts by weight of DOPO derivatives shown in the examples;

[0030] The use of the quenching liquid in the company's production line: the outlet temperature of the profile is controlled at 550 ℃, and 9 tons of aluminum alloy profiles are processed continuously. Slightly dark, no peculiar smell, and no peculiar smell after 2 weeks; PAG, water and additives are supplemented to the initial value, and the profile can be discharged stably.

[0031] Example 3

[0032] Based on 100 parts by weight of the quenching agent as a whole, configure 20 parts by weight of PAG stock solution, 8 parts by weight of quenchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com