Assembly type inclined supporting joint steel frame structure

A technology of oblique bracing and steel frame, applied in building components, building structures, protective buildings/shelters, etc., to achieve the effects of good pull-out resistance, reduced bottom load, and not easy to fall off in pairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

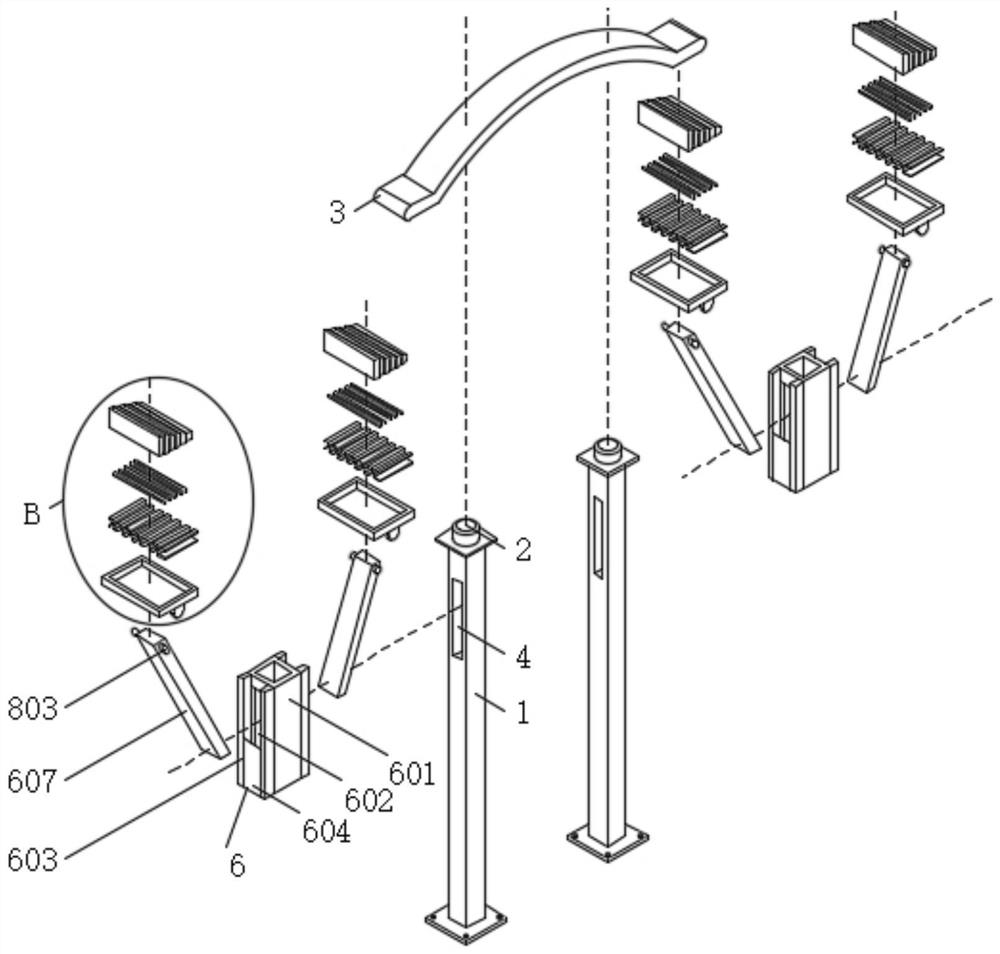

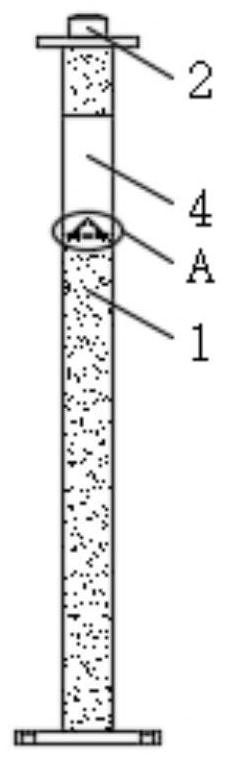

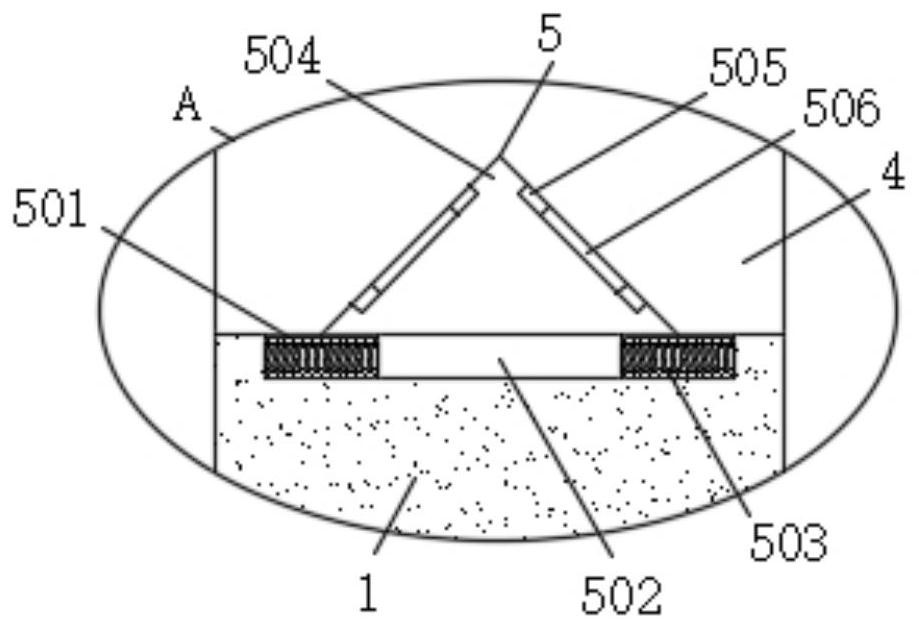

[0037] An assembled obliquely braced node steel frame structure, comprising two receiving beams 1, the tops of the two receiving beams 1 are fixedly connected to the arc-shaped steel frame 3, and a relief The shock bearing 2, the side wall of the receiving beam 1 is provided with a first penetration port 4, and a buffer assembly 5 with a force conversion effect is also arranged in the first penetration port 4, and a diagonal support assembly 6 is inserted into the first penetration port 4 .

[0038] By adopting the above-mentioned technical scheme and utilizing the slope effect of the angle seat, the pressure on one of the inclined support frames can be transferred to the other inclined support frame, and the interaction between the two has good pull-out resistance. It is not easy to fall off in twos, which effectively improves its maximum lateral load capacity, and enhances the stability of the installation node, reduces the load at the bottom of the receiving beam, and enhan...

Embodiment 2

[0051] An assembled obliquely braced node steel frame structure, comprising two receiving beams 1, the tops of the two receiving beams 1 are fixedly connected to the arc-shaped steel frame 3, and a relief The shock bearing 2, the side wall of the receiving beam 1 is provided with a first penetration port 4, and a buffer assembly 5 with a force conversion effect is also arranged in the first penetration port 4, and a diagonal support assembly 6 is inserted into the first penetration port 4 .

[0052] By adopting the above-mentioned technical scheme and utilizing the slope effect of the angle seat, the pressure on one of the inclined support frames can be transferred to the other inclined support frame, and the interaction between the two has good pull-out resistance. It is not easy to fall off in twos, which effectively improves its maximum lateral load capacity, and enhances the stability of the installation node, reduces the load at the bottom of the receiving beam, and enhan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com