Novel drip irrigation tape and preparation method thereof

A drip irrigation belt, a new technology, applied in the field of new drip irrigation belt and its preparation, can solve the problems of fracture, drip irrigation belt explosive tube, etc., achieve excellent toughness and strength, prolong oxidation induction time, and low elongation at break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The novel drip irrigation belt in the present application is made from the raw materials of the dosage shown in Table 1, and is specifically prepared by the following method:

[0037] Preparation of shed film recycled material: choose high-pressure material type shed film waste, clean and pulverize the shed film waste;

[0038] The pulverized shed film waste is granulated under the conditions that the temperature of the first stage is 155 °C, the temperature of the second stage is 165 °C, the temperature of the third stage is 170 °C, the temperature of the fourth stage is 175 °C, and the temperature of the head is 180 °C. , for standby, to obtain the regenerated material of the shed film;

[0039] Preparation of drip irrigation belt recycled material: use low-pressure material type drip irrigation belt waste, wash and pulverize the drip irrigation belt waste;

[0040]The crushed drip irrigation tape waste is granulated under the conditions that the temperature of the f...

Embodiment 2-5

[0044] The new drip irrigation tapes of Examples 2-5 are exactly the same as the preparation methods and types of raw materials of Example 1, the difference is that the dosage of each raw material is different, as shown in Table 1 for details.

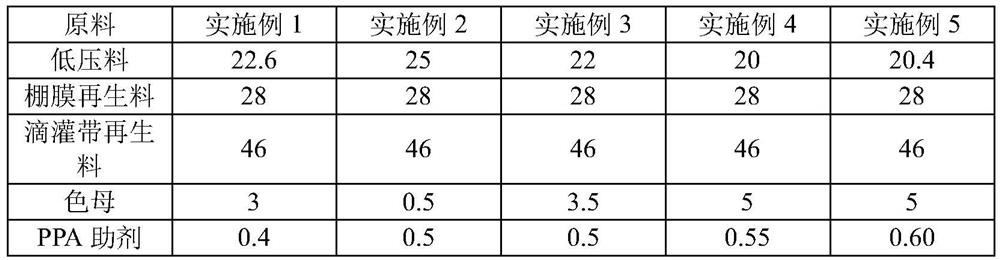

[0045] The dosage of each raw material (unit: kg) of the novel drip irrigation belt of table 1 embodiment 1-5

[0046]

Embodiment 6-8

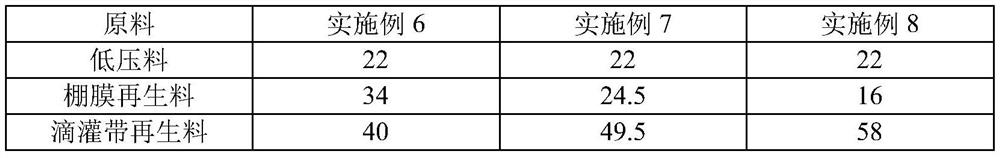

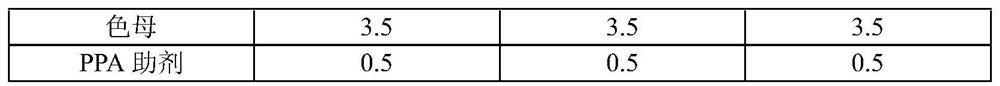

[0048] The new drip irrigation tapes of Examples 6-8 have exactly the same preparation methods and types of raw materials as those of Example 3. The difference is that the dosage of each raw material is different, as shown in Table 2 for details.

[0049] The dosage of each raw material (unit: kg) of the novel drip irrigation belt of table 2 embodiment 6-8

[0050]

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oxidation induction time | aaaaa | aaaaa |

| Oxidation induction time | aaaaa | aaaaa |

| Oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com