Water immersion ultrasonic geometric accuracy calibration system

A geometric accuracy and calibration system technology, applied in the field of geometric measurement, can solve the problems of unreproducible calibration methods, low calibration accuracy, and high calibration difficulty, and achieve the effect of random installation position, high degree of automation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

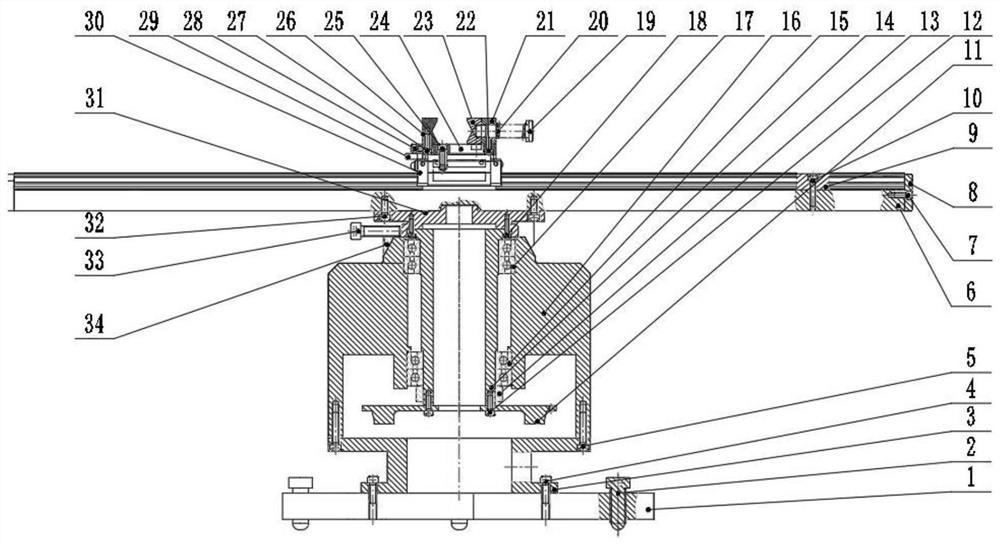

[0071] refer to figure 1 , a preferred embodiment of the present invention provides a water immersion ultrasonic geometric accuracy calibration system, comprising:

[0072] The base includes a bottom support seat 1 and a bottom connection seat 3, and the bottom support seat 1 is provided with several adjustment nails 2 along the circumference; On the upper end surface, the bottom connection seat 3 adopts a hollow structure and the side wall is provided with a threading hole for the convenience of the line passing through;

[0073] Rotary measuring device, including:

[0074] The vertical axis mounting base 16 is fixed on the upper end surface of the bottom connecting base 3 by the second hex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com