Tension maintaining structure, tension maintaining device and vibrating wire type equipment

A holding device and pulling force technology, applied in the field of pulling force holding device, pulling force holding structure, and vibrating wire equipment, can solve the problems of small pulling force and small actual pulling force, and achieve stable pulling force, improve stability, Easy-to-fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

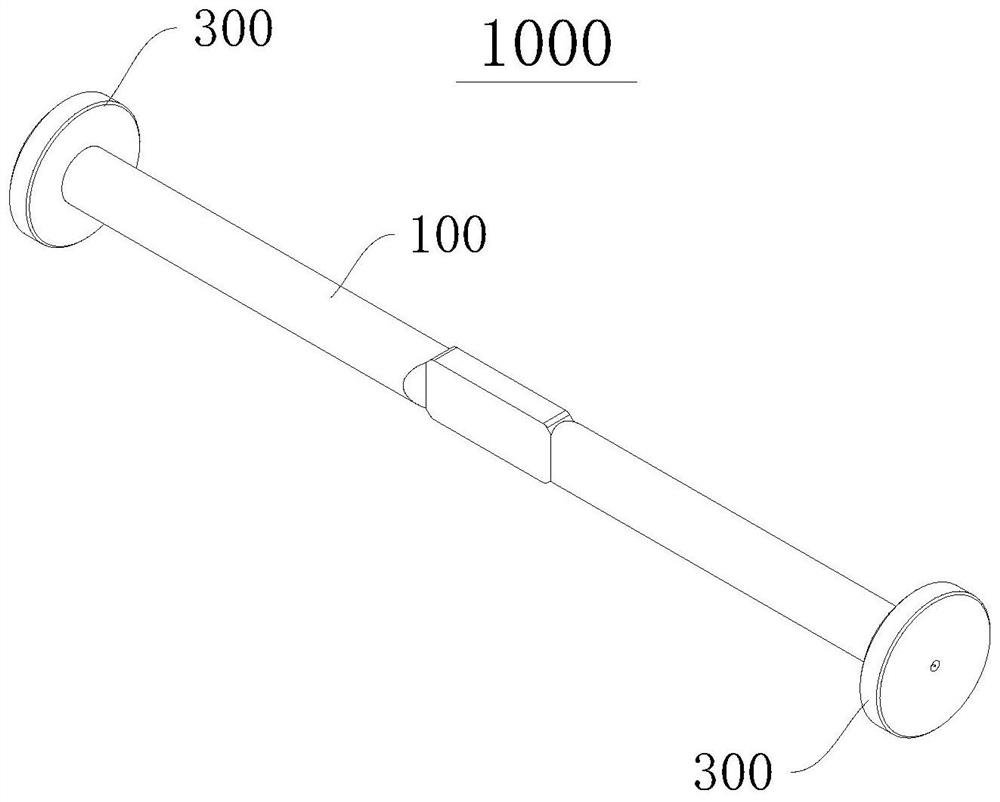

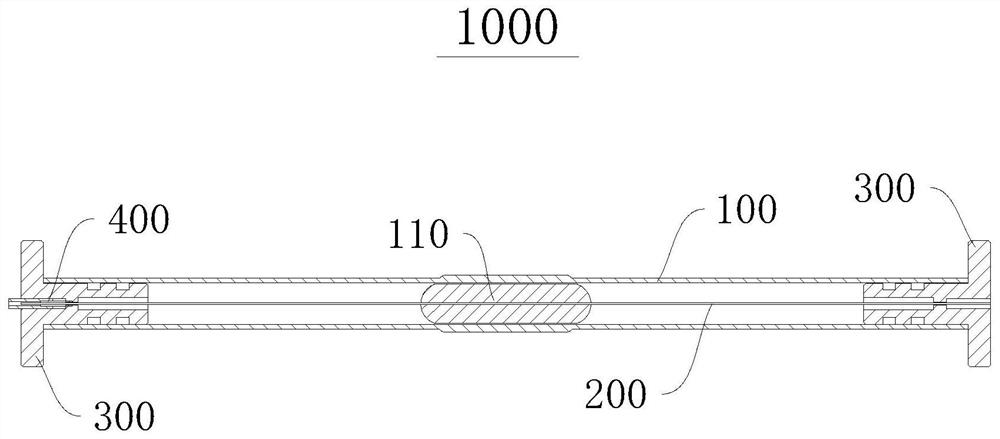

[0061] Please refer to figure 1 and figure 2 , the present embodiment provides a tension maintaining device 1000, suitable for vibrating wire equipment, tension piles, etc., which can keep the tension of the tension string 200 passing through the equipment in the above equipment stable.

[0062] The tension holding device 1000 includes: a protective cover 100 , a base 300 and a fixing assembly 400 . Both ends of the protective cover 100 are equipped with a base 300 , and the pull string 200 can be accommodated in the protective cover 100 and passed through the base 300 . The fixing component 400 fixes the stay string 200 to the base 300 so that the tension of the stay string 200 remains constant.

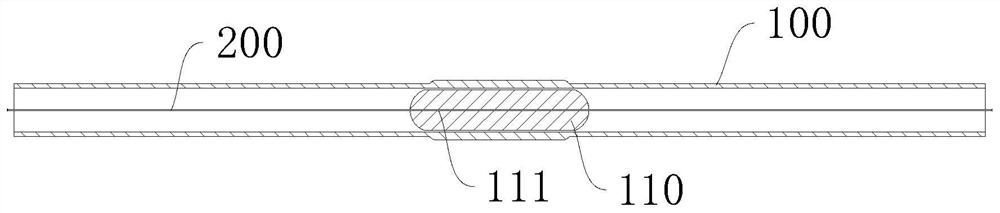

[0063] Please refer to image 3 , the protective sheath 100 is cylindrical as a whole, and the inner cavity of the protective sheath 100 is a hollow pipe passing through the protective sheath 100 along the axial direction. The stay string 200 is accommodated in the inner cavity...

Embodiment 2

[0116] Please refer to Figure 16 , and combined with Figure 15 , the present embodiment provides a vibrating wire device 2000 , the vibrating wire device 2000 includes a pulling string 200 , electromagnetic components (not shown in the figure) and a tension maintaining device 1000 .

[0117] The pull string 200 of the vibrating string device 2000 is fixed by a tension holding device 1000, the pull string 200 is arranged in the protective cover 100, and the two ends of the pull string 200 extend into the extension section 320 and the seat body 310 respectively, and are connected by the connecting piece 410 and stiffener 420 are fixed.

[0118] The electromagnetic components are installed in the hollow pipe of the protective cover to detect the change of the vibration frequency of the string 200 .

[0119] The vibrating wire device 2000 uses the tension holding device 1000 to fix the tension string, and the tension of the tension string remains unchanged at the initial prese...

Embodiment 3

[0122] Please refer to Figure 17 , this embodiment provides a tension holding structure 3000 , the tension holding structure 3000 includes the base 300 , the connecting piece 410 and the reinforcing piece 420 of the tension holding device 1000 in the first embodiment.

[0123] The base 300 can be used to connect with other objects, such as being installed on a concrete pile. In this way, by cooperating the base 300 and the fixing assembly 400, one end of the stay string 200 can be fixed, and the other end of the stay string 200 can be fixed. It can be used to connect with other objects that need to be subjected to tension, and the tension holding structure 3000 can continuously provide stable tension to other objects.

[0124] The tension maintaining structure 3000 can be applied to tighten and reinforce electric piles, and can be used to tension electric wires, but is not limited thereto.

[0125] Please refer to Figure 18 , in a modification of this embodiment, the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com