Horizontal logistics flying probe testing machine

A flying probe testing machine and logistics technology, applied in printed circuit testing, electronic circuit testing, measuring electricity and other directions, can solve the problems of limited structure design, reduce testing efficiency, increase testing cost, etc., achieve good versatility, improve testing Efficiency, satisfying the effect of test work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

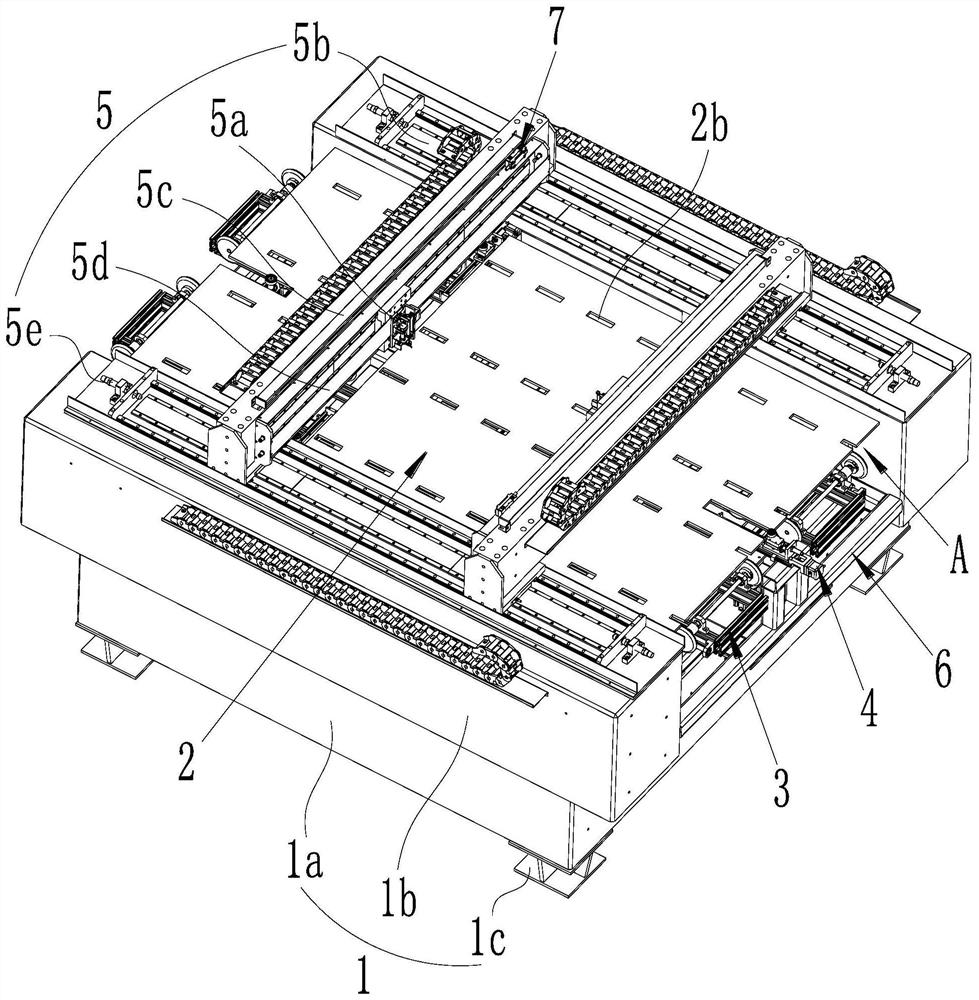

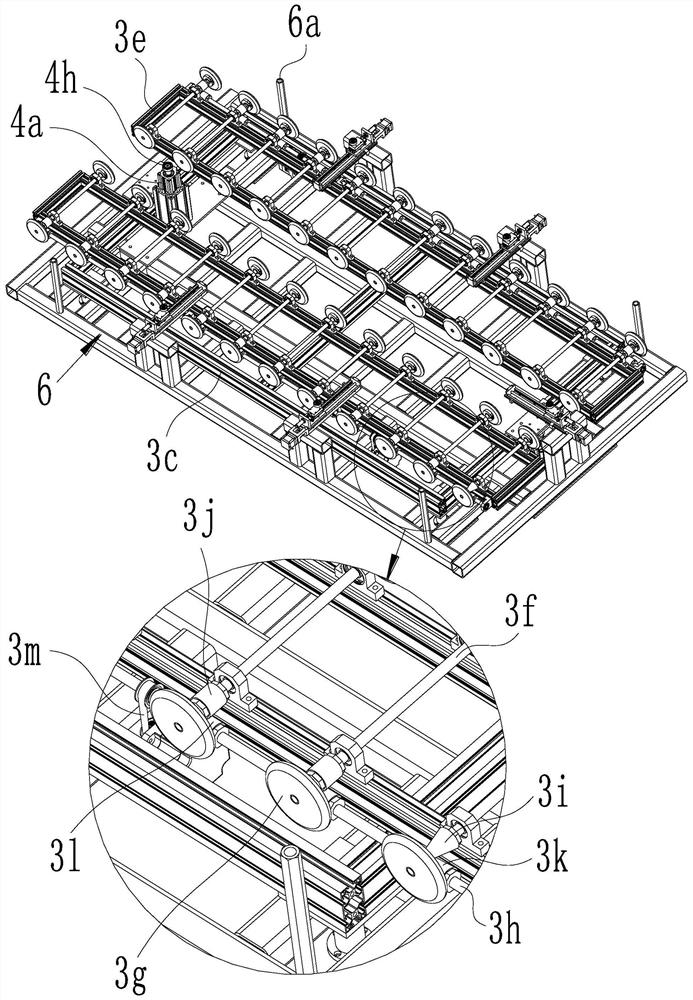

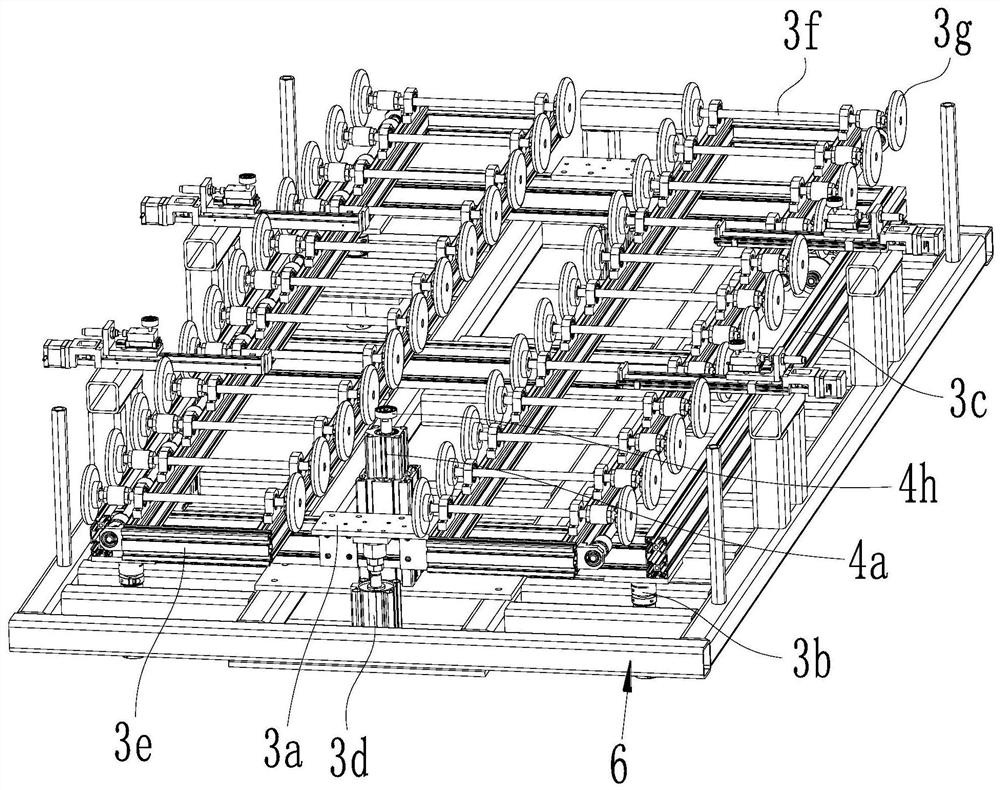

[0040] Such as figure 1 As shown, a horizontal logistics flying probe testing machine mainly includes an equipment mounting base 1 and a detection platform 2 installed on the equipment mounting base 1 , a logistics feeding mechanism 3 , a glass substrate centering mechanism 4 and a detection mechanism 5 .

[0041] The equipment mounting base 1 includes a base 1a, two side bases 1b oppositely arranged on the upper part of the base 1a, and several legs 1c installed on the lower part of the base 1a. By adjusting the height of each leg 1c, the whole set of equipment can be leveled.

[0042] See figure 1 with Figure 5 , the base 1a and the two side bases 1b jointly form a "U"-shaped structure, the detection platform 2 is installed between the two side bases 1b, and is surrounded by the base 1a and the two side bases 1b to form an equipment installation cavity A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com