Mud pressure feed type horizontal directional drilling engineering geological investigation hole internal testing device

A testing device and horizontal directional technology, applied in directional drilling, drilling equipment and methods, measurement, etc., can solve the problems of inability to directly apply horizontal holes, time-consuming, and inability to ensure instrument safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

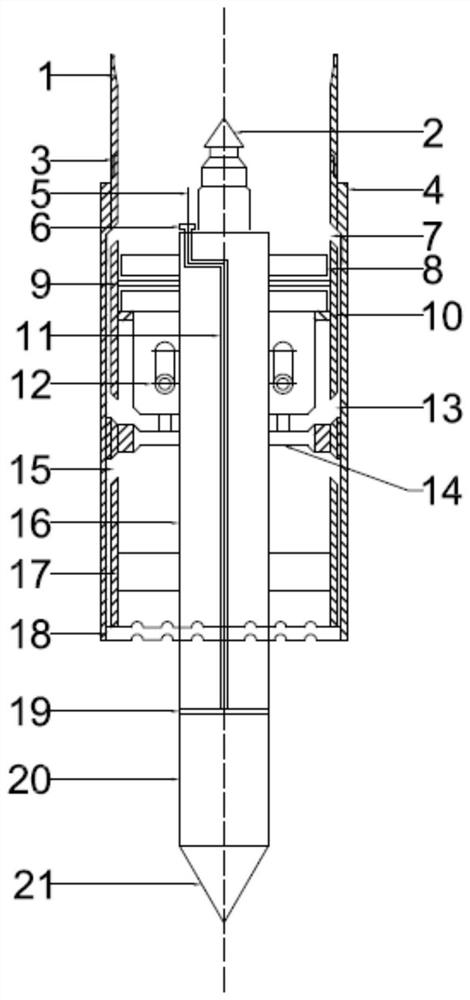

[0018] see below figure 1 A mud pressure-feeding type horizontal directional drilling engineering geological survey hole testing device according to the present invention will be described in detail.

[0019] like figure 1 As shown, the mud pressure-feeding type horizontal directional drilling engineering geological survey hole testing device provided by the present invention includes a drilling tool, a sealing pressure-feeding mechanism, an in-position reporting mechanism and an overall mechanism of the testing device. Wherein, drilling tool comprises single-wall drill pipe 1, double-wall drill pipe 4, centering ring 17 and drill bit 18, and drill bit 18 is connected at the bottom of double-wall drill pipe 4, and centering ring 17 is positioned at the inside of double-wall drill pipe 4 and is close to it. At the bottom, the single-wall drill pipe 1 and the double-wall drill pipe 4 are threadedly connected by a joint 3, and the single-wall drill pipe 1 is a conventional drill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com