A kind of antibacterial and insect-proof heat-generating composite yarn and preparation method thereof

A technology for preventing moth-eaten and yarn, applied in the field of yarn production, can solve the problems of easy moth-eaten, difficult to store, etc., and achieve the effects of preventing electrostatic layer from falling off, improving strength and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

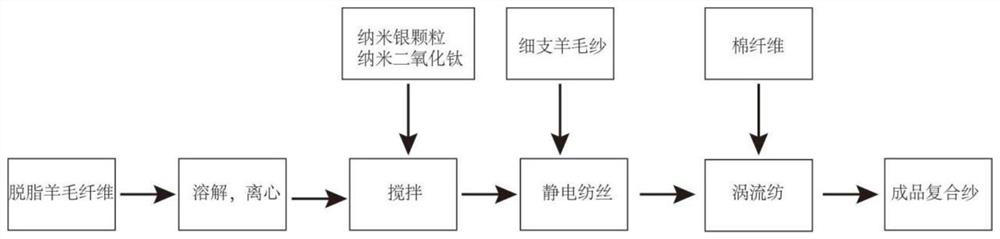

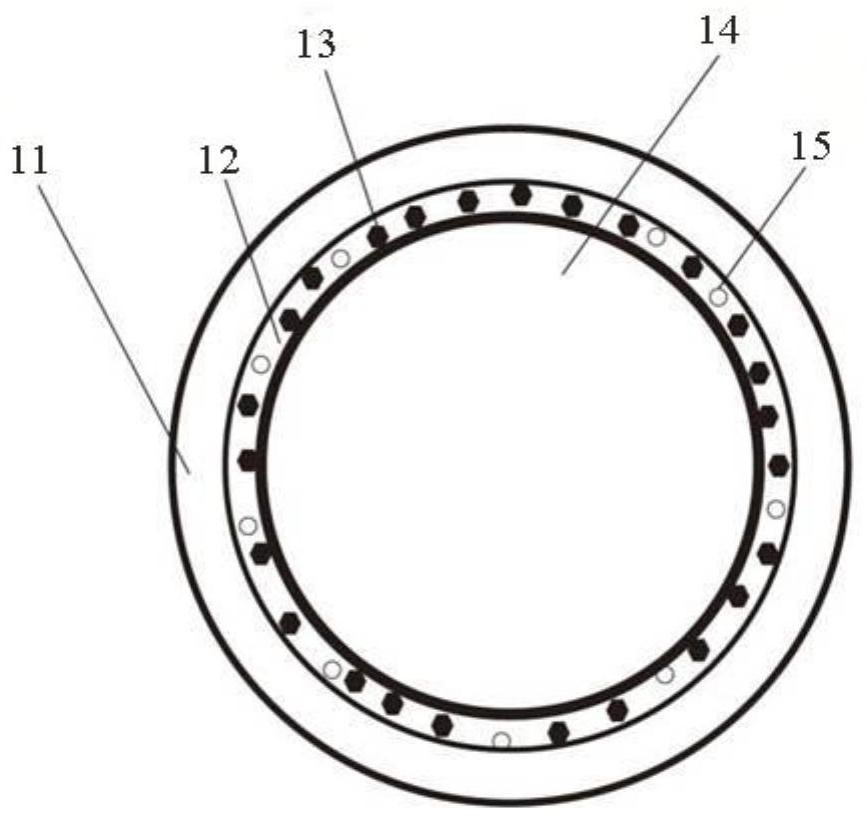

[0032] See Figure 1-2 The present embodiment provides a method for preparing an antibacterial and insect-proof heat-generating composite yarn, comprising the following steps:

[0033] (1) with skimming wool fiber drying, dissolving, centrifugation, add nano silver 15 and nano titanium dioxide 13, wherein nano silver 15 and skimming wool fiber mass ratio are 1:20, and the mass ratio of nano titanium dioxide 13 and skimming wool fiber is 1: 10; Stir, and fix to the surface of the fine-count wool yarn 14 by electrospinning to form a regenerated keratin functional layer 12, thereby obtaining a primary yarn, wherein the thickness of the fine-count wool yarn 14 is 280D / 660F;

[0034] (2) The primary yarn obtained in step (1) is fed into the vortex spinning equipment, wherein the take-up ratio is 0.7, the roller tension is 150CN, the traverse angle is 15deg, and the size of the cotton collector is 4mm; it is blended with cotton fiber and formed on the surface of the primary yarn Th...

Embodiment 2

[0037] The present embodiment provides a method for preparing an antibacterial and insect-proof heat-generating composite yarn, comprising the following steps:

[0038] (1) drying the degreasing wool fiber, dissolving, centrifuging, adding nano silver and nano titanium dioxide, wherein the mass ratio of nano silver and degreasing wool fiber is 1:20, and the mass ratio of nano titanium dioxide and degreasing wool fiber is 1:12; stirring; , fixed to the surface of fine-count wool yarn by electrospinning to form a regenerated keratin functional layer, thereby obtaining primary yarn, wherein the thickness of fine-count wool yarn is 280D / 660F;

[0039] (2) The primary yarn obtained in step (1) is fed into the vortex spinning equipment, wherein the take-up ratio is 0.7, the roller tension is 150CN, the traverse angle is 15deg, and the size of the cotton collector is 4mm; blended with cotton fiber, on the surface of the primary yarn A cotton fiber structural reinforcement layer is fo...

Embodiment 3

[0042] The present embodiment provides a method for preparing an antibacterial and insect-proof heat-generating composite yarn, comprising the following steps:

[0043] (1) drying the degreasing wool fiber, dissolving, centrifuging, adding nano silver and nano titanium dioxide, wherein the mass ratio of nano silver and degreasing wool fiber is 1:30, and the mass ratio of nano titanium dioxide and degreasing wool fiber is 1:10; stirring; , fixed to the surface of fine-count wool yarn by electrospinning to form a regenerated keratin functional layer, thereby obtaining primary yarn, wherein the thickness of fine-count wool yarn is 280D / 660F;

[0044] (2) The primary yarn obtained in step (1) is fed into the vortex spinning equipment, wherein the take-up ratio is 0.7, the roller tension is 150CN, the traverse angle is 15deg, and the size of the cotton collector is 4mm; blended with cotton fiber, on the surface of the primary yarn A cotton fiber structural reinforcement layer is fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com