Thermal power plant main steam pressure control method

A main steam pressure and pressure control technology, which is applied in the direction of electric fluid pressure control, fluid pressure control, non-electric variable control, etc., can solve the problems of frequent fluctuations in main steam pressure, and achieve the effect of improving the performance of AGC and primary frequency modulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

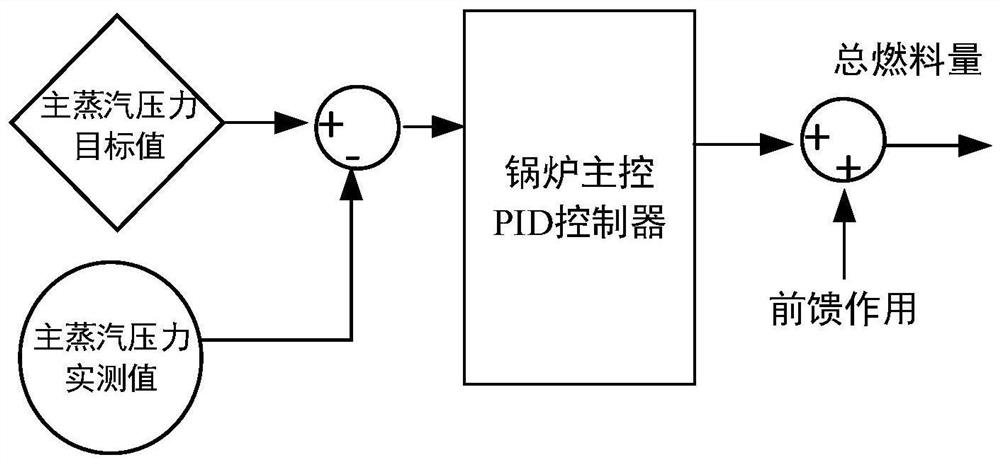

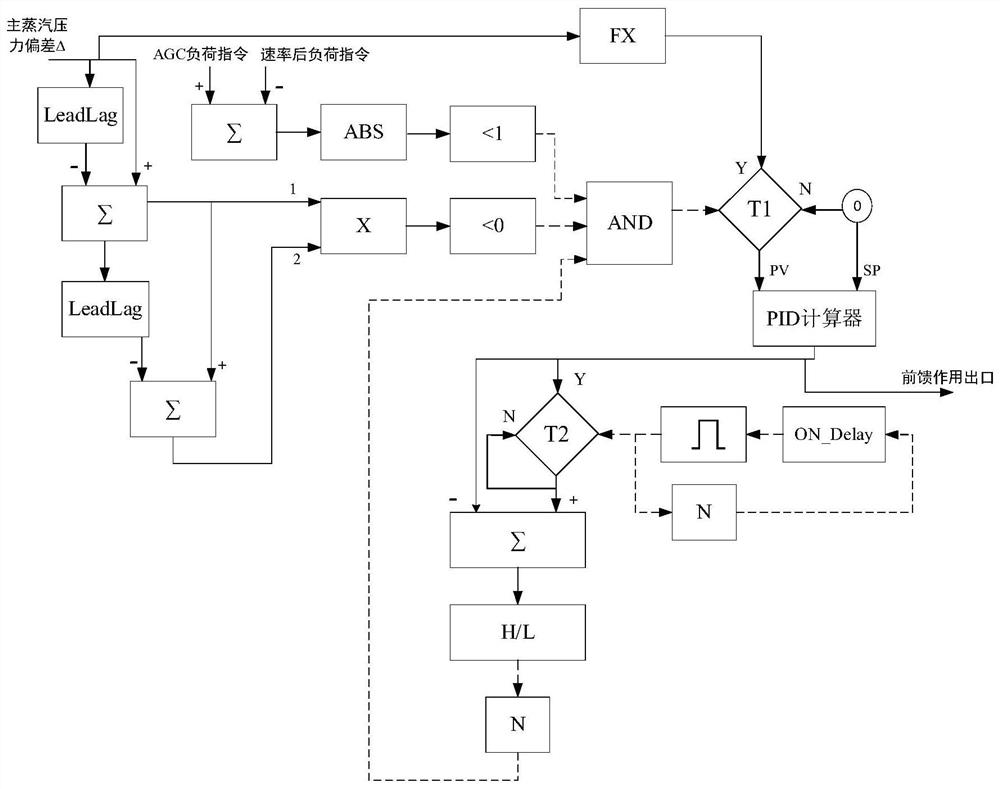

[0044] To solve the problem of frequent fluctuations of the main steam pressure, it is necessary to solve the problem of the balance point of the fuel quantity of the unit under different coal qualities. The invention provides a method for controlling the main steam pressure of a thermal power plant such as figure 2 As shown, it includes adding a feed-forward value to the main control PID controller of the boiler, that is, the feed-forward PID controller. The feed-forward PID controller includes a PID calculator with pure integral action and a PID input control module based on it and a PID The calculation module moves the balance point of the fuel quantity through the feed-forward PID controller to accumulate the deviation of the main steam pressure. in:

[0045] (1) PID input control module

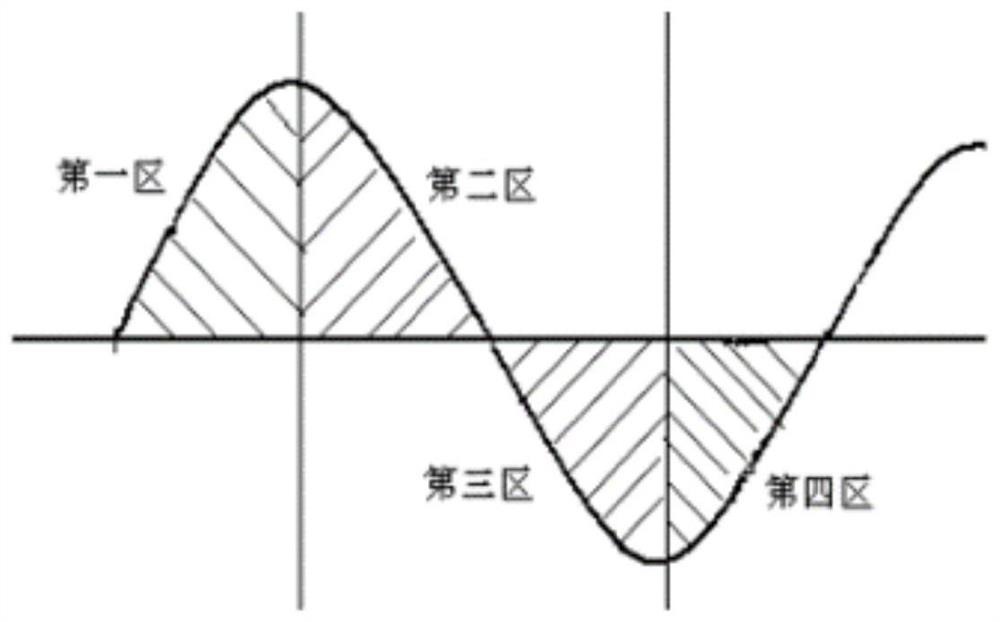

[0046] Main steam pressure deviation: Δ=SP-PV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com