Primary frequency modulation method of single-shaft combined cycle unit of single-burning low heat value blast furnace gas

A combined cycle unit, blast furnace gas technology, applied in the direction of combined combustion mitigation, mechanical equipment, steam engine installations, etc., can solve the problems of low calorific value and difficult combustion stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

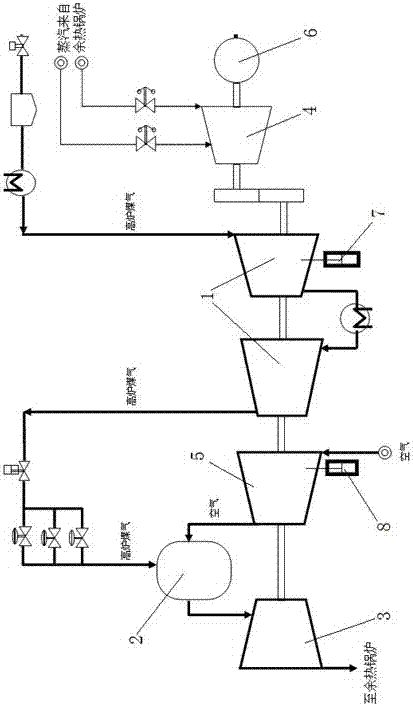

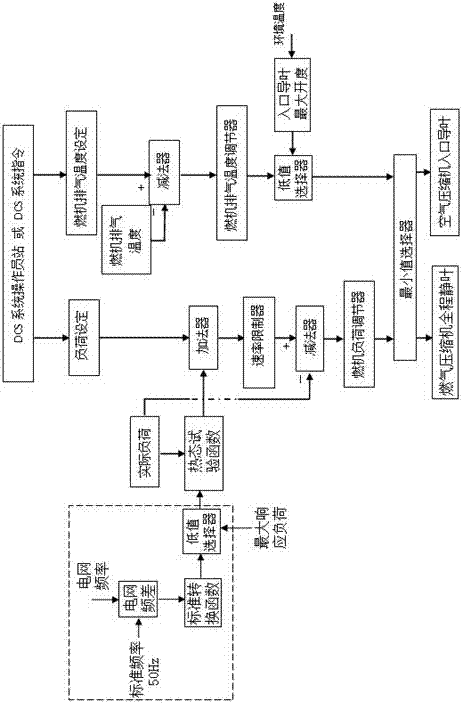

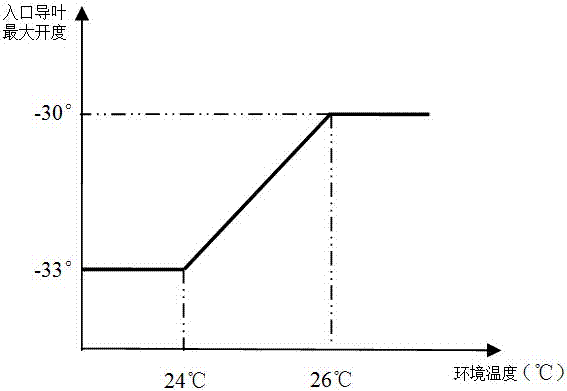

[0030] Such as figure 1 As shown, it is a block diagram of the system operation principle of the single-shaft combined cycle unit applied in the present invention. The blast furnace gas is compressed by the multi-stage gas compressor 1 after dedusting and sent to the combustion chamber 2 for combustion, and then the gas turbine 3 does work. The gas turbine 3 The high-temperature exhaust gas is sent to the waste heat boiler to heat the feed water to generate steam, and then enters the steam turbine 4 to do work. The combustion air used in the combustion chamber 2 is supplied by the air compressor 5, and the gas flow can be adjusted by adjusting the angle of the full-range stator blade 7 of the gas compressor 1. The adjustment of the amount of combustion-supporting air is realized by adjusting the angle of the inlet guide vane 8 of the air compressor 5; when the gas compressor 1 is multi-stage, the adjustment of the gas amount is usually adjusted by the full-range vane of the fir...

Embodiment 2

[0048] The input terminal of the DCS distributed control system detects that the grid frequency is 50.073 Hz, and the angle of the entire stator blade is 62°. First, the required load response value is calculated to be -3MW, and the amplitude is less than 6MW. Therefore, the actual load response value is equal to -3MW. The output of the machine load regulator reduces the command of the full-range stator blade angle of the gas compressor, so that the full-range stator blade angle is reduced from 62° to 60.5°, and the corresponding actual adjustment value of the full-range stator blade angle is 1.5°. Unit load is reduced by 2.6MW within 30 seconds, with a maximum reduction of 3MW.

Embodiment 3

[0050] The input terminal of the DCS distributed control system detects that the grid frequency is 49.887Hz, and the angle of the stator blades throughout the process is 72.2°. First, the load response requirement value is calculated to be +6MW, and the amplitude is equal to 6MW. Therefore, the actual load response value is equal to +6MW. The output of the machine load regulator increases the command of the full-range stator blade angle of the gas compressor, so that the full-range stator blade angle is opened from 72.2° to 74.8°, and the corresponding actual adjustment value of the full-range stator blade angle is 2.6°. Unit load increases by 4.2MW within 30 seconds, with a maximum increase of 6.3MW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com