Implant delivery system and inner tube thereof

A technology for delivery systems and implants, applied in stents and other directions, can solve the problems of complicated and difficult release, large volume of the post-release mechanism, and easily unstable bending after release, so as to achieve no axial shortening, and improve the ease of implementation and performance. Practicality, release the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

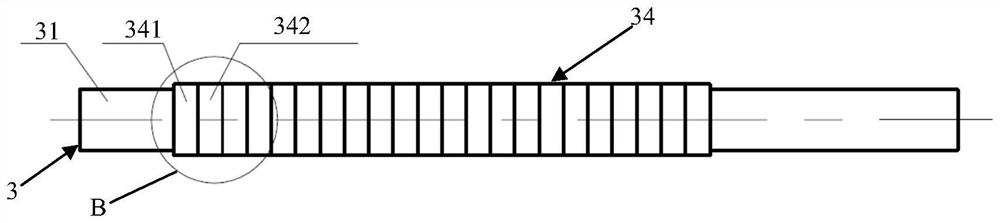

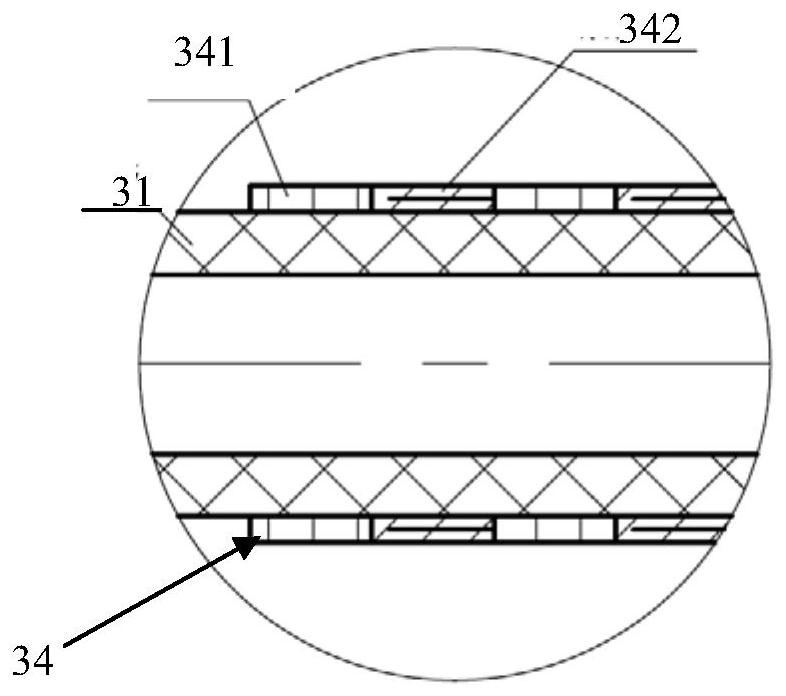

[0041] In this embodiment, the plurality of friction bodies 34 are distributed along the axial direction of the inner tube body 31 , and the first friction layers 341 and the second friction layers 342 are distributed alternately along the axial direction of the inner tube body 31 .

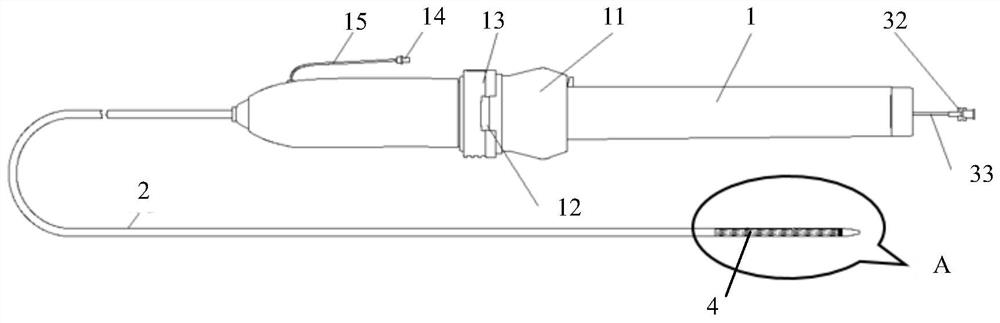

[0042] figure 2 for figure 1 Schematic diagram of the structure of the inner tube at A. See figure 2 , the inner tube 3 includes an inner tube main body 31, the outer surface of the distal end of the inner tube main body 31 is alternately provided with first friction layers 341 and second friction layers 342 in the axial direction, and the first friction layer 341 is composed of a friction layer having a first friction coefficient. The second friction layer 342 is made of a material with a second coefficient of friction. The material with the first coefficient of friction is a material with a high coefficient of friction, preferably silica gel or polyurethane; the material with the second co...

Embodiment 2

[0046] It is different from the alternate distribution of the first friction layer 341 and the second friction layer 342 in Embodiment 1. The friction body 34 of this embodiment includes the first friction layer 341 and the second friction layer 342 distributed along the radial direction of the inner pipe main body, and the first friction layer 341 is located on the inner pipe main body 31 and between the second friction layer 342 . See Image 6 , the friction layer 34 provided on the outer surface of the inner pipe body 31 at the place where the bracket 4 is placed has a first side 343 and a second side 344; the first side 343 has a first friction layer 341, and the second side 344 has a second friction layer 342 . When the friction body 34 is in the first state, the friction body 34 is folded in the axial direction of the inner tube main body 31, the first side 343 has a first surface 3431 and a second surface 3432, and at least the second surface 3432 of the first side 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com