Cleaning arm for atomizer and using method of cleaning arm

A technology for cleaning arms and atomizers, used in spray devices, liquid spray devices, etc., can solve the problems of surface scaling, inconvenience, loss of atomization function, etc., to extend service life, reduce maintenance costs, and keep the surface dry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

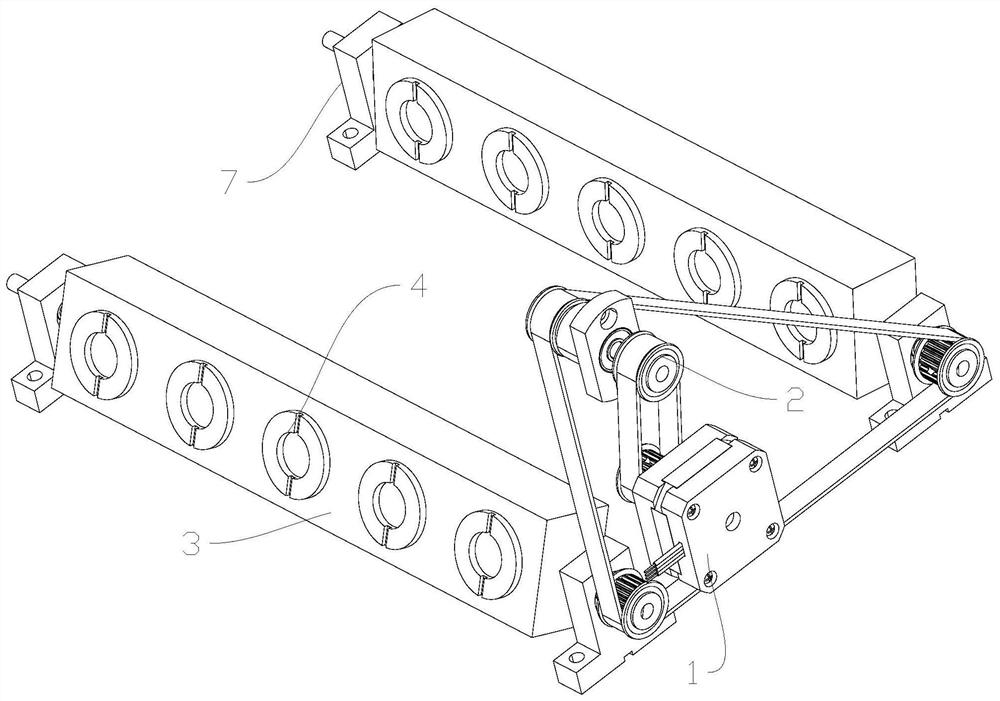

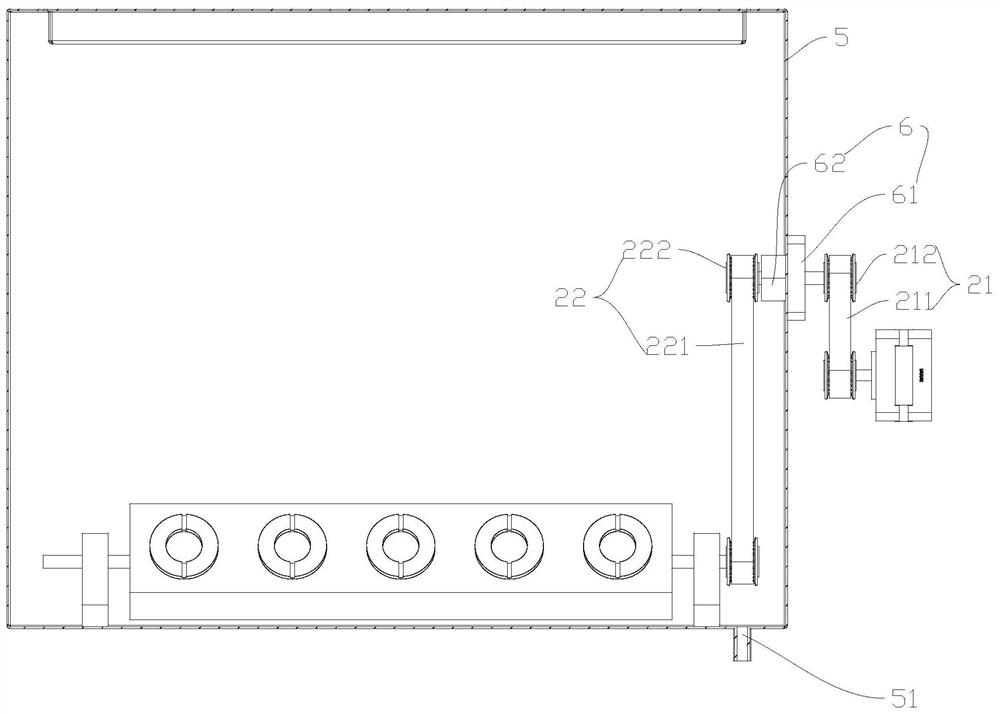

[0022] like figure 1 Shown, a kind of cleaning arm for atomizer, comprising: stepper motor 1, band rotating assembly 2 and atomizing arm 3; the output end of stepper motor 1 is connected with the input end of band rotating assembly 2; The output end of the assembly 2 is connected with one end of the atomizing arm 3; the upper surface of the atomizing arm 3 is screwed with several atomizing sheets 4; Through the starting of the stepping motor 1, the first driving belt 211 rotates with the rotating assembly 2 so that the atomizing arm 3 can follow the rotation direction of the rotating assembly 2, and the atomizing sheets 4 arranged at equal intervals on the atomizing arm 3 also rotate. It changes with the change of the atomizing arm 3 , thereby changing the initial position of the atomizing sheet 4 on the atomizing arm 3 .

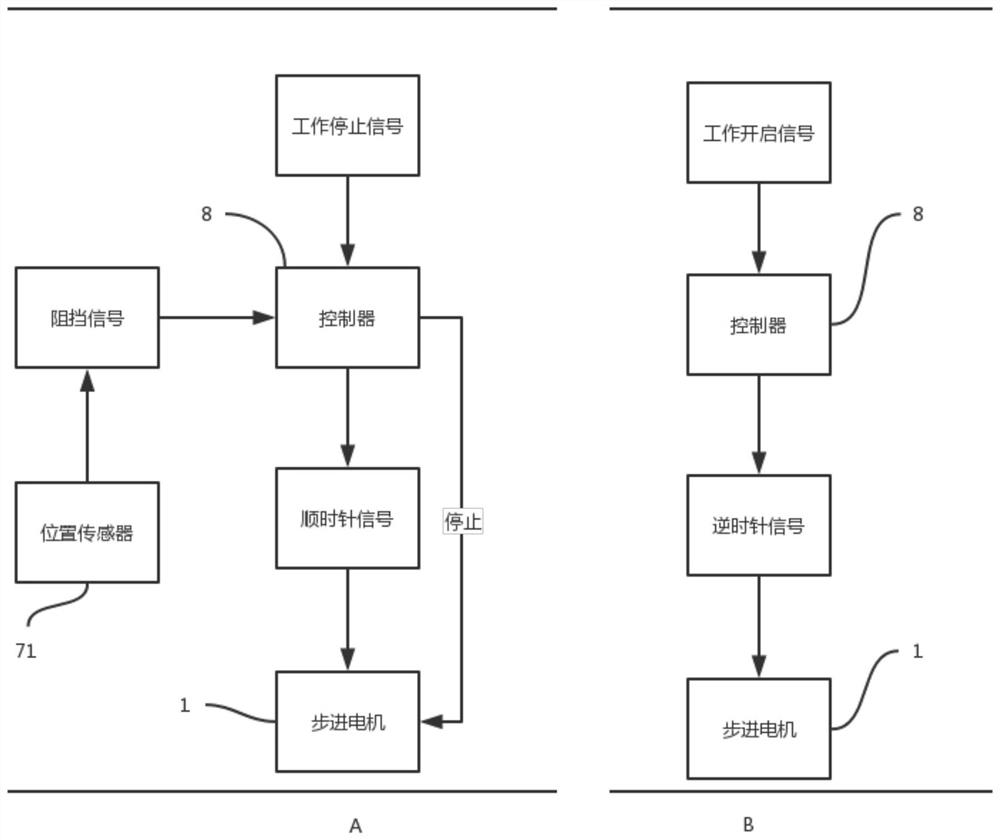

[0023] like figure 2 As shown in middle A, a method for using a cleaning arm for an atomizer includes: detecting a work stop signal through the controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com