A deformable polishing disc based on thermoplastic material

A thermoplastic material, grinding and polishing technology, used in grinding tools, grinders, optical surface grinders, etc., can solve the problems of surface deformation of grinding and polishing discs, removal of large materials, high rigidity requirements, and achieve low cost, improve stability, and improve processing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make those skilled in the art better understand the solutions of the present application, the following will clearly and completely describe the technical solutions in the embodiments of the present application with reference to the accompanying drawings in the embodiments of the present application.

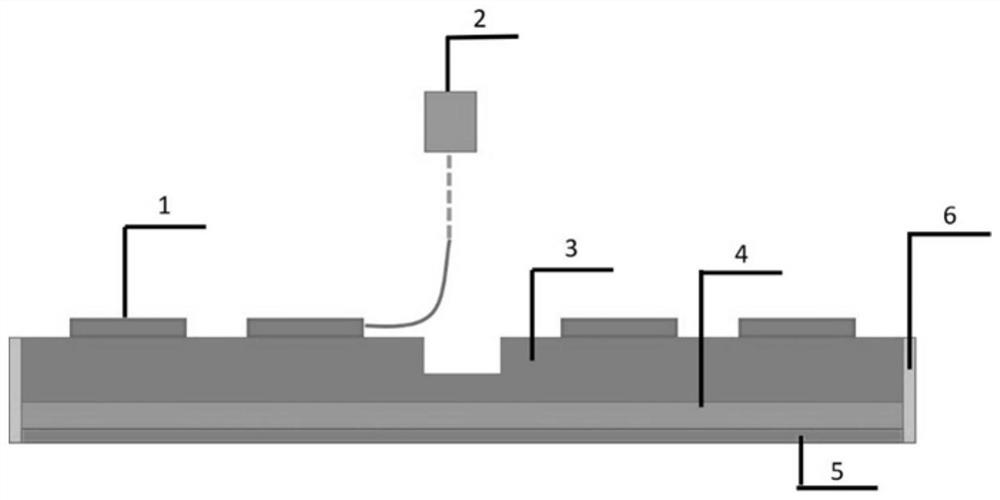

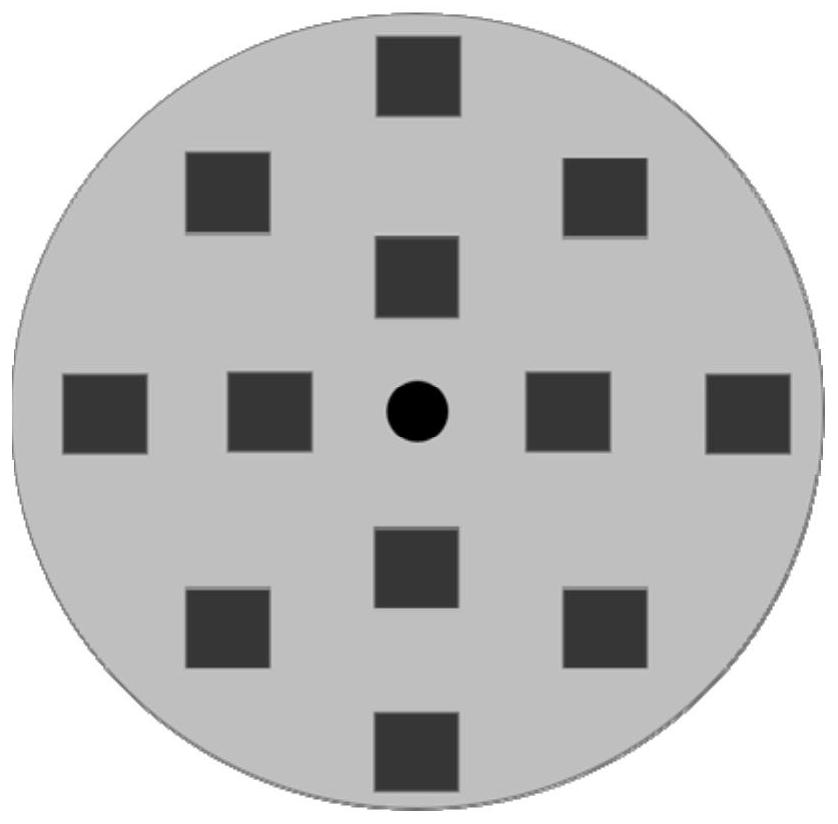

[0025] see figure 2 , which is a schematic cross-sectional view of a thermoplastic material-based deformation grinding disc provided in this embodiment. A deformation grinding and polishing disc based on thermoplastic material, comprising two or more electric heating sheets 1, a numerical control power supply 2, a sealing ring 6, and a rigid base 3, a flexible layer 4, and a deformed base plate 5 which are of the same size and are all disc structures;

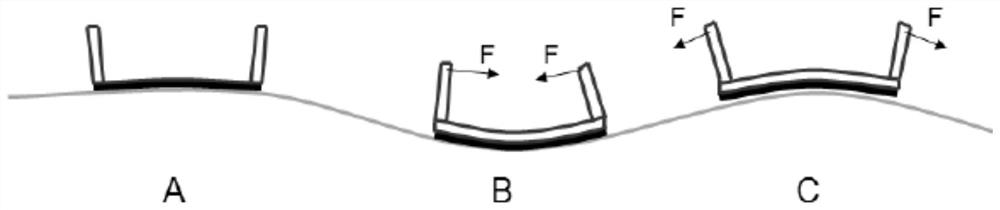

[0026] The electric heating sheet 1 is evenly arranged on the rigid base 3 and heats the rigid base 3; at the same time, a flexible layer 4 and a deformable substrate 5 are sequentially laid under the rigid ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com