Resuscitator tray suitable for cold storage tubes of various specifications, and application method

A resuscitator and cold storage tube technology, applied in the direction of internal accessories, etc., can solve the problems of troublesome use of cold storage tubes, delaying time, affecting the work efficiency of staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

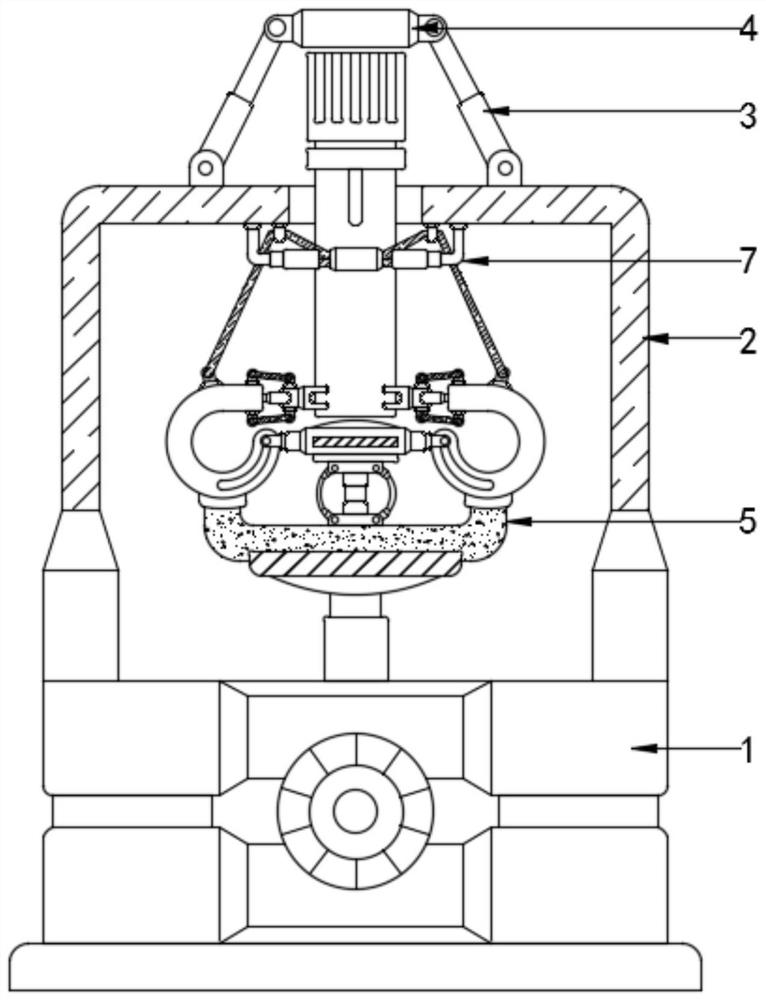

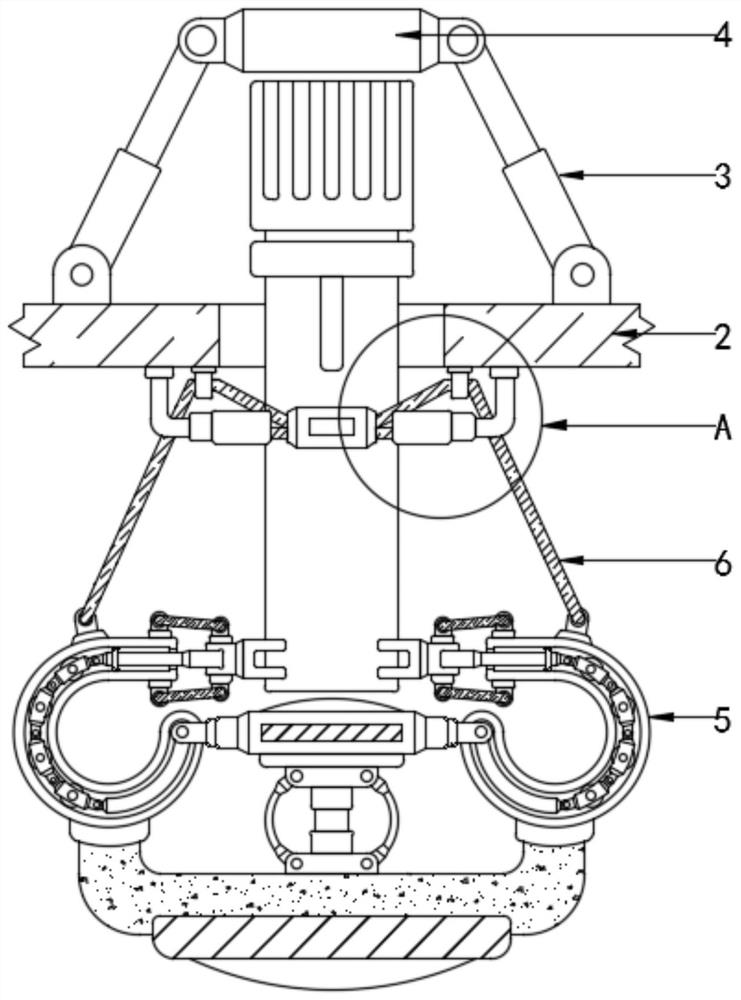

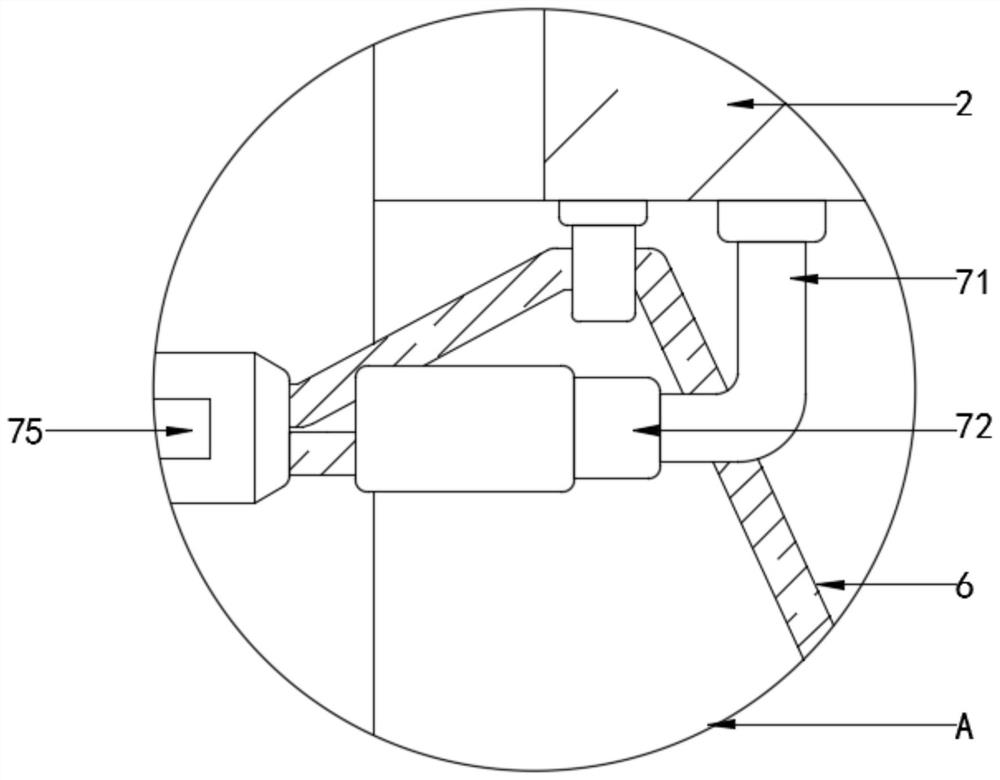

[0038] A suitable method for cold storage tubes of various specifications, comprising the following steps:

[0039] S0, pull up the lower pressure plate 4, and drive the constant pressure rod 3 to turn over;

[0040] S1. Insert a 2ml cold storage tube through the shell 2, and release the lower pressing plate 4, so that the lower pressing plate 4 can generate pressure and restrictive force on the cold storage tube;

[0041] S2. The cold storage tube of 2ml moves down under the action of pressure, and pushes the pressure plate 53 to move down by 1cm, while the elastic iron sheet 52 bends;

[0042] S3, the arc rod 552 moves 1 cm on the pressure plate 53 and the multi-section rod 54, and pushes the connecting head 553 and the moving block 554 to move;

[0043] S4, the extrusion rod 555 moves 1 cm under the action of the moving block 554, and pushes the limit frame 557 to limit the cold storage tube, and the elastic cord 556 also produces a stretch of 1 cm during the process;

[...

Embodiment 2

[0048] A suitable method for cold storage tubes of various specifications, comprising the following steps:

[0049] S0, pull up the lower pressure plate 4, and drive the constant pressure rod 3 to turn over;

[0050] S1. Insert a 3ml cold storage tube through the shell 2, and release the lower pressing plate 4, so that the lower pressing plate 4 can generate pressure and restrictive force on the cold storage tube;

[0051] S2. The cold storage tube of 3ml moves down under pressure, and pushes the pressure plate 53 to move down by 2cm, while the elastic iron sheet 52 bends;

[0052] S3, the arc rod 552 moves 2 cm on the pressure plate 53 and the multi-section rod 54, and pushes the connecting head 553 and the moving block 554 to move;

[0053] S4, the extrusion rod 555 moves 2 cm under the action of the moving block 554, and pushes the limit frame 557 to limit the cold storage tube, and the elastic cord 556 also produces a stretch of 2 cm during the process;

[0054] S5, unde...

Embodiment 3

[0058] A suitable method for cold storage tubes of various specifications, comprising the following steps:

[0059] S0, pull up the lower pressure plate 4, and drive the constant pressure rod 3 to turn over;

[0060] S1. Insert a 5ml cold storage tube through the shell 2, and release the lower pressing plate 4, so that the lower pressing plate 4 can generate pressure and restrictive force on the cold storage tube;

[0061] S2. The cold storage tube of 5ml moves down under the action of pressure, and pushes the pressure plate 53 to move down by 3cm, while the elastic iron sheet 52 bends;

[0062] S3, the arc rod 552 moves 3 cm on the pressure plate 53 and the multi-section rod 54, and pushes the connecting head 553 and the moving block 554 to move;

[0063] S4, the extrusion rod 555 moves 3 cm under the action of the moving block 554, and pushes the limit frame 557 to limit the cold storage tube, and the elastic cord 556 also produces a stretch of 3 cm during the process;

[...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap