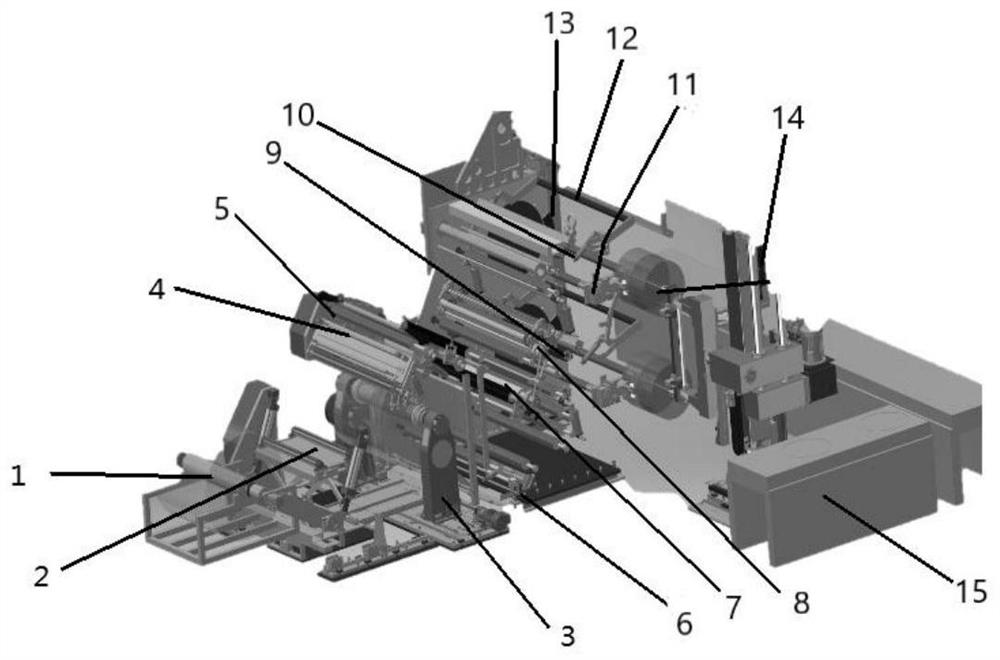

Full-automatic four-axis splitting machine

A fully automatic, shaft-divided technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of manual cutting and other problems, and achieve the effect of enhanced safety, easy sorting and rectification, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

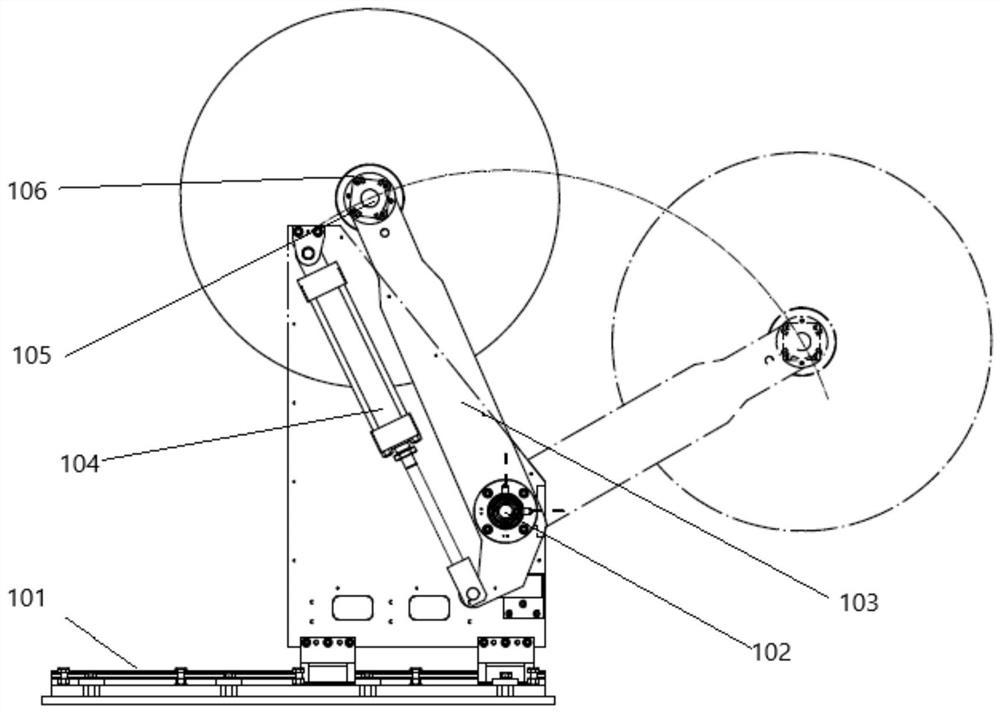

[0051] Implementation method: After the original raw material of the first volume is cut and rolled, it stays on the two winding shafts near the inner side, starts the PLC control program, and the upper and lower two 360-degree turntables are combined with the function of ordinary motor + reducer and the function of oil cylinder. Under the push, it turns 180 degrees from inside to outside, and transfers the 2 rewinding shafts carrying the finished coil materials to the outer side of the rewinding operation side, and at the same time, the 2 unloaded reeling shafts are transferred to the inner side to continue the next round of cutting, Winding work. So repeatedly.

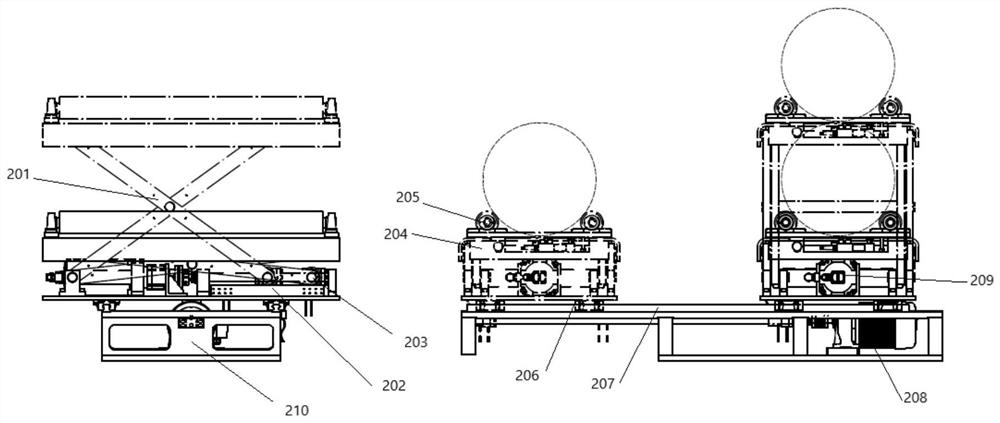

[0052] Fully automatic unloading rack: It is located outside the slitting machine and is an independent mechanism used with the automatic four-axis slitting machine.

[0053] Implementation method: The finished coil material transferred to the outer side of the winding operation side is driven by the pusher motor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com