Glass blowing equipment

A technology of glass products and equipment, which is applied in the field of glass product blowing equipment, can solve the problems of low efficiency of artificial blown glass products and difficulty in ensuring product quality, and achieve the effect of consistent shape and size, improved efficiency, and guaranteed product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is further described in detail by specific embodiments:

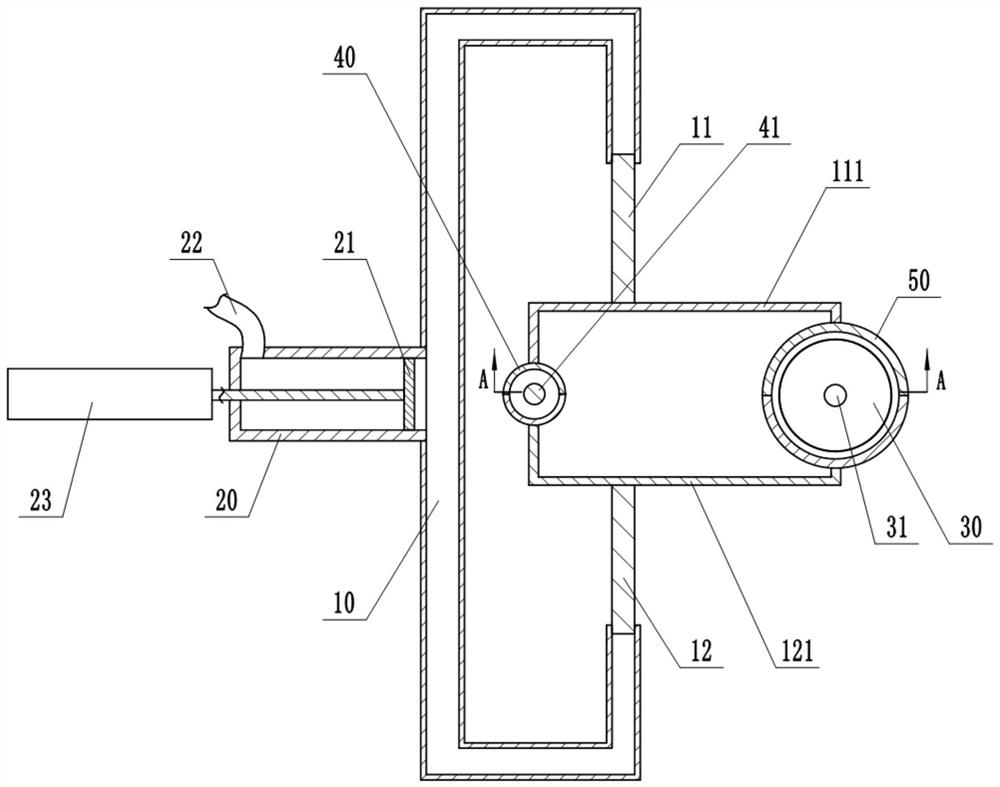

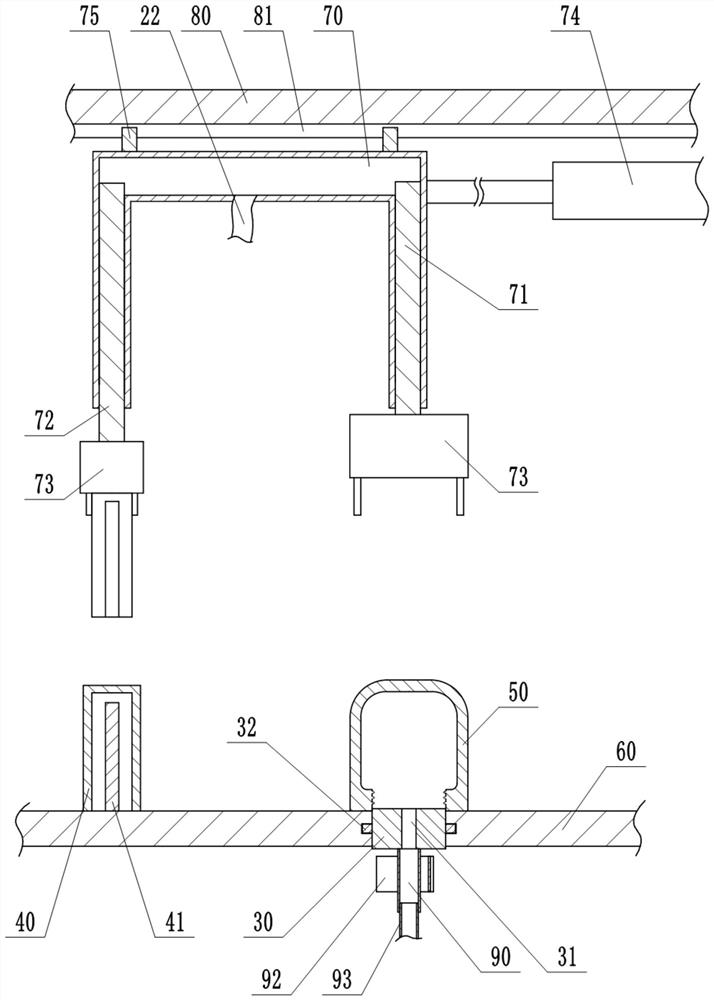

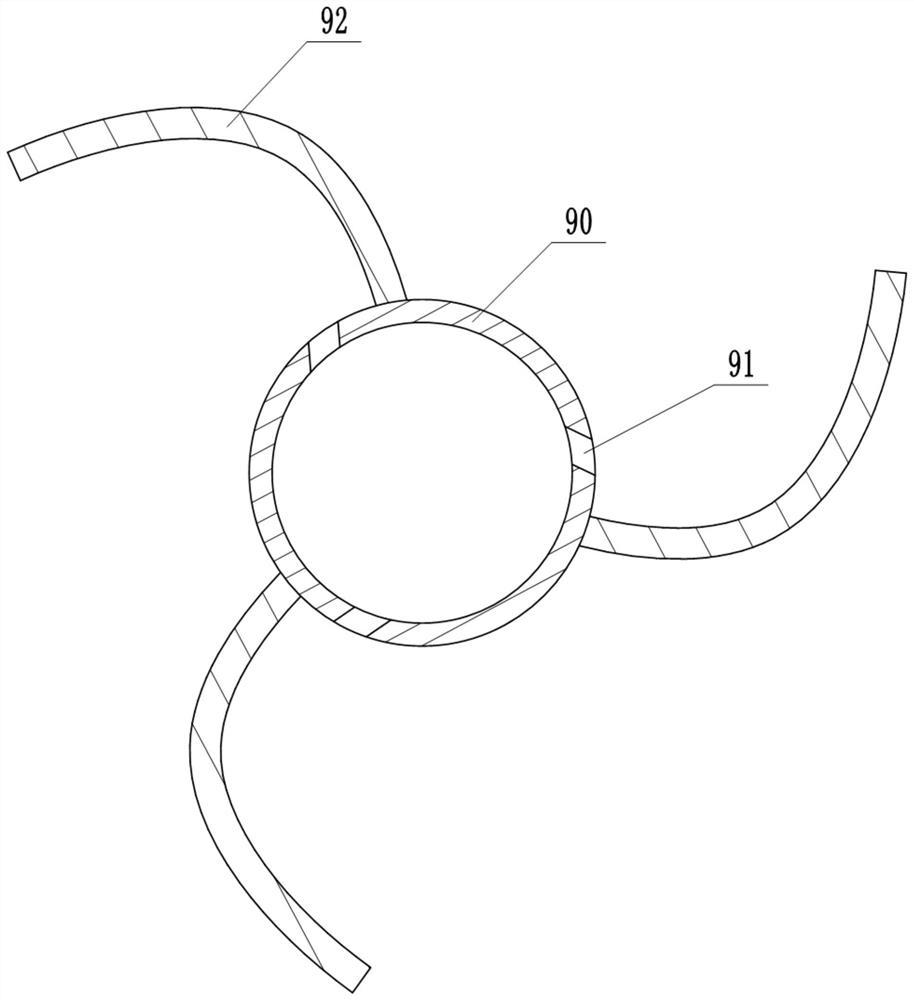

[0020] Reference numerals in the accompanying drawings include: connecting pipe 10, first push rod 11, first bracket 111, second push rod 12, second bracket 121, piston cylinder 20, piston 21, flexible tube 22, second drive part 23, chassis 30, vent 31, annular block 32, press mold 40, inner core 41, blow mold 50, table 60, communication pipe 70, second plunger 71, first plunger 72, clamping 73 , the first driving part 74 , the slider 75 , the frame 80 , the guide rail 81 , the conduit 90 , the through hole 91 , the arc blade 92 , and the air pipe 93 .

[0021] This embodiment is basically as figure 1 , figure 2 Shown: glass blowing equipment, including table 60, pressing mechanism, blowing mechanism, feeding mechanism and power mechanism. The pressing mechanism is used to press the molten glass frit into a shape that is convenient for subsequent blowing. The pressing mechanism includes two symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com