Large-flow anti-blocking inspection well cover

An anti-clogging, manhole cover technology, applied in waterway systems, water conservancy projects, artificial islands, etc., can solve problems such as poor drainage of manhole covers, avoid the impact of traffic and public safety, increase drainage, and prevent blocking of drainage holes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

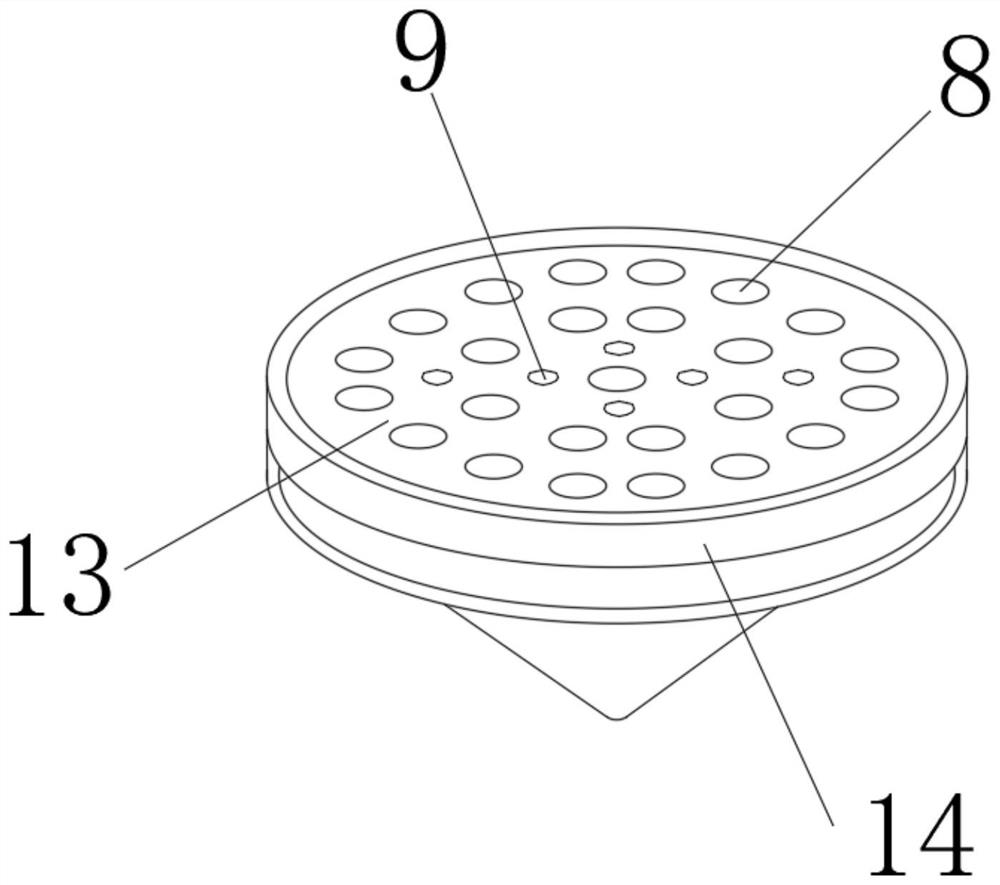

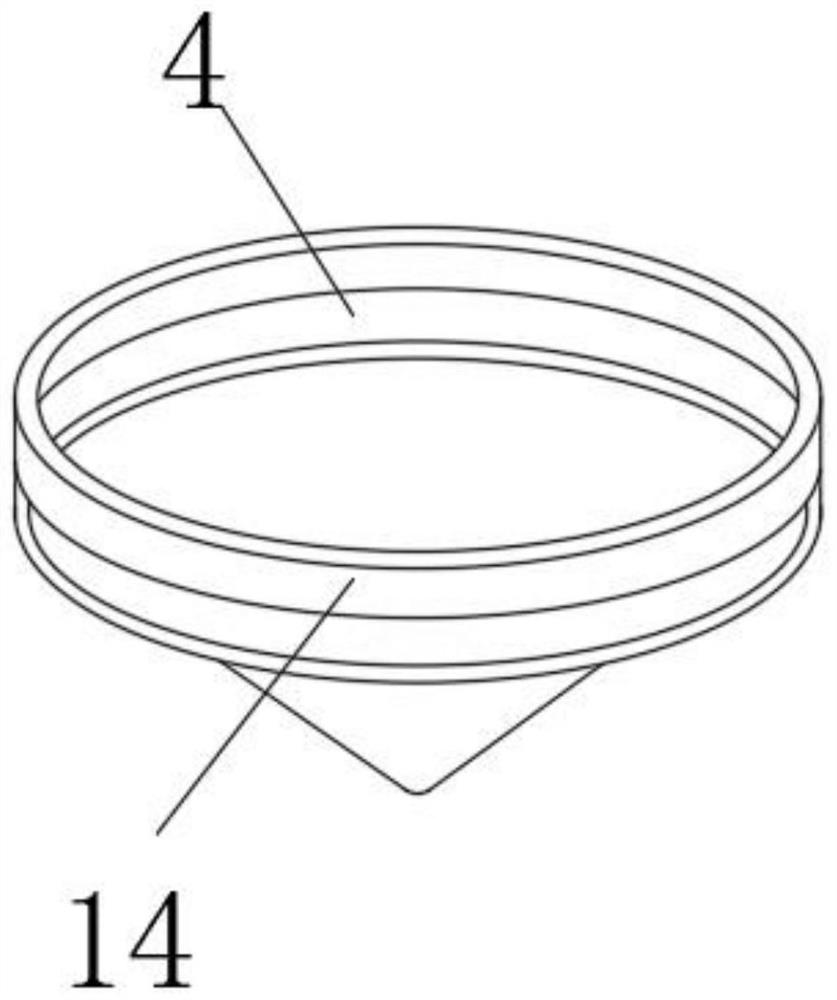

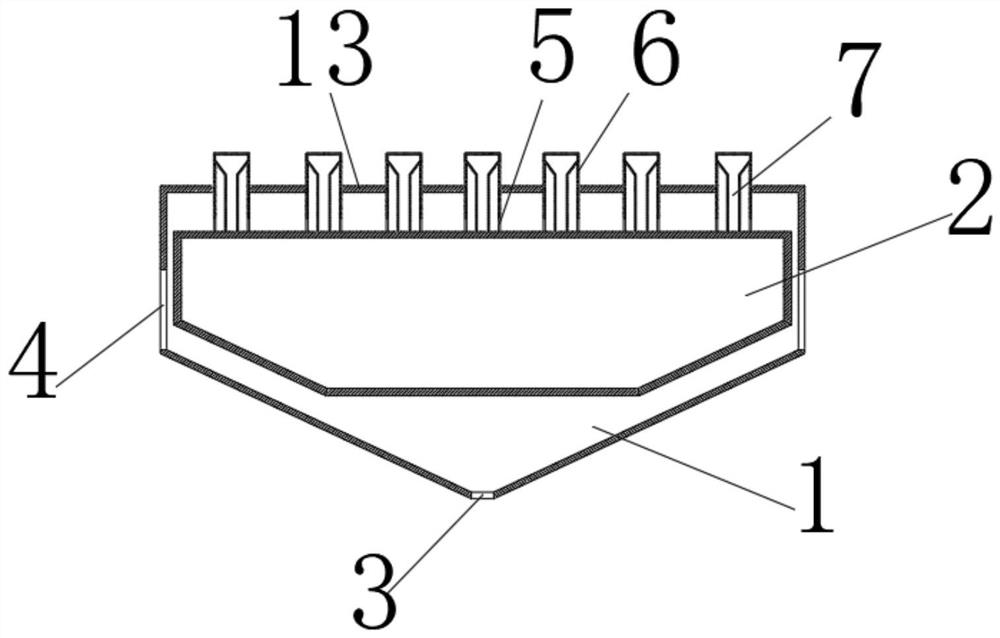

[0026] Such as Figure 1 to Figure 3 As shown, a large-flow anti-clogging manhole cover includes an outer shell 14 fixedly connected to the inner wall of the sewer and a cover plate 13 arranged on the top of the outer shell 14, and several cover components are slidably arranged on the cover plate 13. The outer casing 14 includes a cavity 1 inside, and a control part connected with the cover assembly is arranged in the cavity 1, and the control part controls the cover assembly according to the amount of accumulated water in the cavity 1. The degree of movement on the cover plate 13 changes the amount of water entering the cover plate 13 .

[0027] The control part includes a hollow trapezoidal buoy 2, the bottom of the buoy 2 does not fit the cavity 1, the top is fixedly connected to the pole 7, and the bottom of the buoy 2 does not fit the cavity 1 for the purpose of Reserve enough space to prevent the bottom of the buoy 2 from being too tight with the cavity 1, resulting in ...

Embodiment 2

[0031] Such as figure 1 , figure 2 , Figure 4 and Figure 5 As shown, a large-flow anti-clogging manhole cover includes an outer shell 14 fixedly connected to the inner wall of the sewer and a cover plate 13 arranged on the top of the outer shell 14, and several cover components are slidably arranged on the cover plate 13. The outer casing 14 includes a cavity 1 inside, and a control part connected with the cover assembly is arranged in the cavity 1, and the control part controls the cover assembly according to the amount of accumulated water in the cavity 1. The degree of movement on the cover plate 13 changes the amount of water entering the cover plate 13 .

[0032] In this embodiment, the cover assembly includes a "T"-shaped strut 7 that runs through the cover plate 13, and the bottom of the strut 7 is provided with a limit plate 12. The interior of the strut 7 is hollow and the bottom is sleeved with Sliding rod 11, the bottom of the limiting plate 12 is provided wi...

Embodiment 3

[0037] Such as figure 1 , figure 2 and Figure 6 As shown, a large-flow anti-clogging manhole cover includes an outer shell 14 fixedly connected to the inner wall of the sewer and a cover plate 13 arranged on the top of the outer shell 14, and several cover components are slidably arranged on the cover plate 13. The outer casing 14 includes a cavity 1 inside, and a control part connected with the cover assembly is arranged in the cavity 1, and the control part controls the cover assembly according to the amount of accumulated water in the cavity 1. The degree of movement on the cover plate 13 changes the amount of water entering the cover plate 13 .

[0038] The cover plate 13 is provided with a first water inlet 9 and a second water inlet 8 sleeved on the outside of the pole 7. The first water inlet 9 is mainly used for drainage when the rainfall is small, and the flowing water passes through the first water inlet. The water outlet 9 enters the cavity 1, and is discharged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com