Miniature turbojet igniter

An igniter and turbojet technology, which is used in machines/engines, jet propulsion devices, turbines/propulsion fuel delivery systems, etc., can solve problems such as difficulty, prevent potential safety hazards, improve atomization effects, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

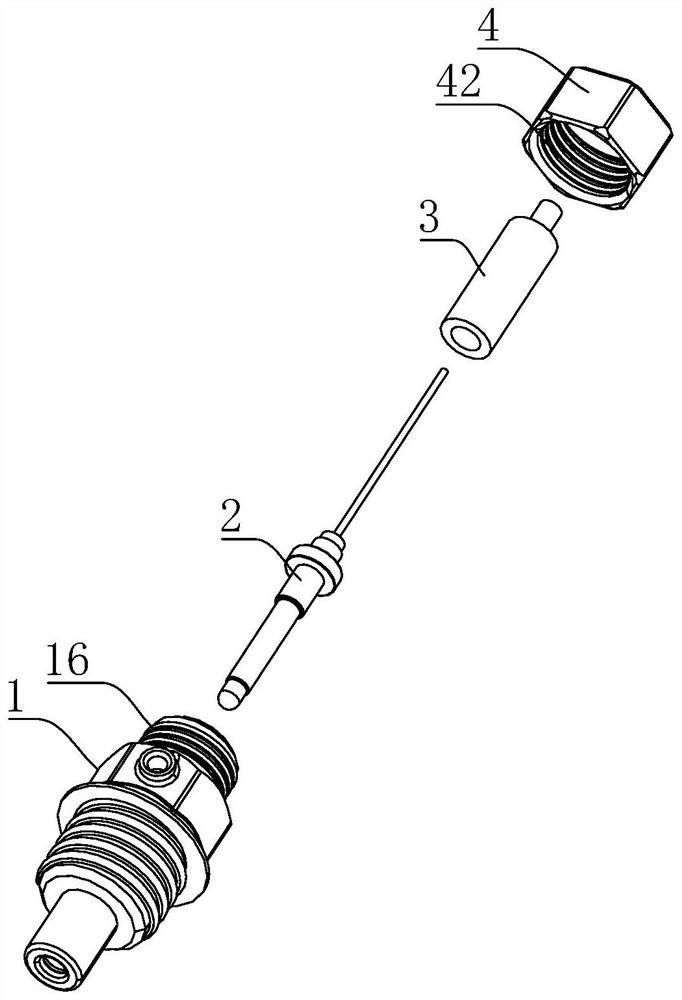

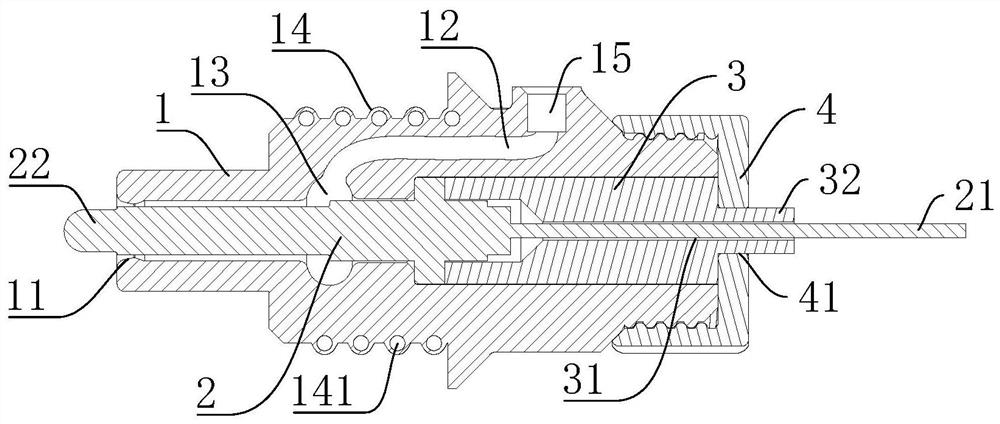

[0027] A miniature turbojet igniter, comprising an igniter housing 1, a heating core 2, an insulating ceramic body 3 and a cap 4; the igniter housing 1 is a hollow shell and wraps the insulating ceramic body 3, The insulating ceramic body 3 has a shaft hole 31 along the axial direction, the heating core 2 is inserted through the shaft hole 31 and exposes its positive end 21, and the cap 4 is connected to the igniter housing 1 The head, and the central hole 41 of the cap 4 surrounds the protruding part 32 of the insulating ceramic body 3; the negative end 22 of the heating core 2 passes through the shrinkage outlet at the tail of the igniter housing 1 11 and extend outward; the interior of the igniter housing 1 has an oil pipeline 12 and a pressure stabilizing chamber 13, and the oil passage communicates with the pressure stabilizing chamber 13.

Embodiment 2

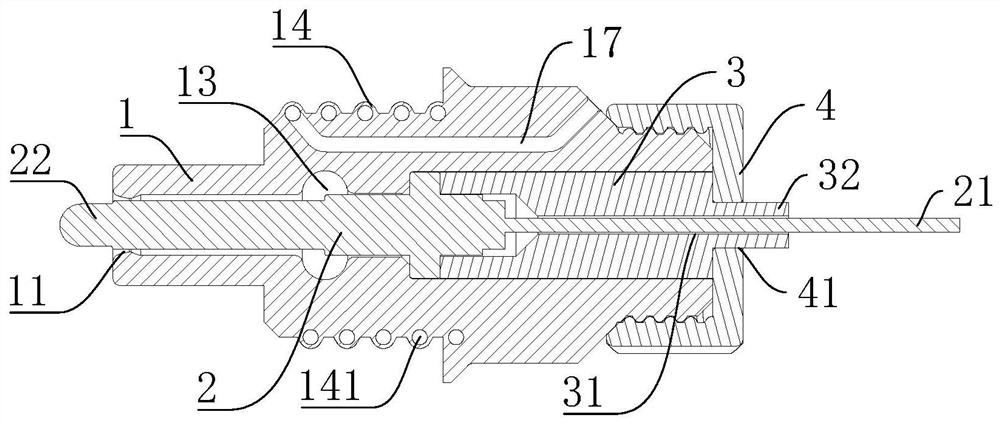

[0029] A miniature turbojet igniter, comprising an igniter housing 1, a heating core 2, an insulating ceramic body 3 and a cap 4; the igniter housing 1 is a hollow shell and wraps the insulating ceramic body 3, The insulating ceramic body 3 has a shaft hole 31 along the axial direction, the heating core 2 is inserted through the shaft hole 31 and exposes its positive end 21, and the cap 4 is connected to the igniter housing 1 The head, and the central hole 41 of the cap 4 surrounds the protruding part 32 of the insulating ceramic body 3; the negative end 22 of the heating core 2 passes through the shrinkage outlet at the tail of the igniter housing 1 11 and extend outward; the interior of the igniter housing 1 has an oil pipeline 12 and a pressure stabilizing chamber 13, and the oil passage communicates with the pressure stabilizing chamber 13.

[0030] The present invention can increase the initial velocity of the oil, improve the atomization effect, and increase the distance...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap