Flow guide pipe of gas turbine stator blade in heat pump system and preparation method

A gas turbine and heat pump system technology, which is applied to mechanical equipment, heat treatment equipment, heat treatment furnaces, etc., can solve problems such as insufficient strength, inconsistent deformation, and different thermal expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

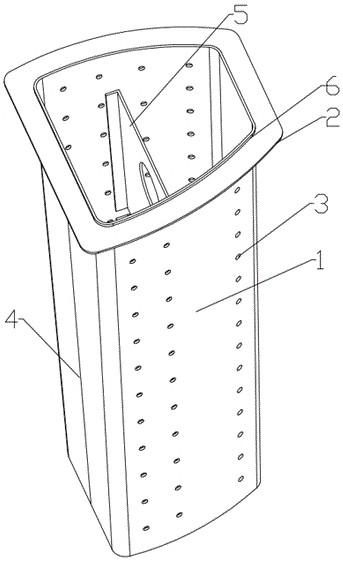

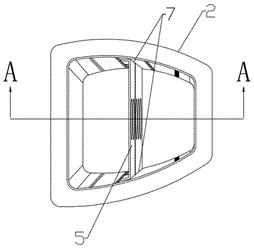

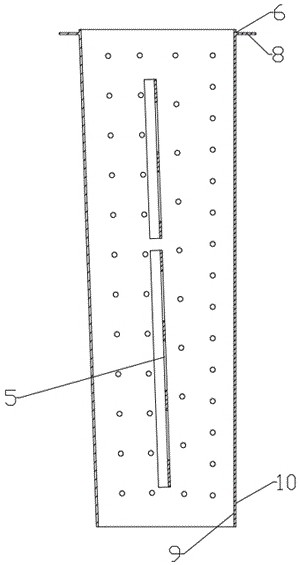

[0050] Such as Figure 4 As shown, a guide pipe for a gas turbine stator blade in a heat pump system includes a ring pipe 1' and an end face 2'. Several cooling holes 3' are arranged on the ring pipe 1', and the ring pipe 1' and the end face 2' are integrally formed. The end face 2' is used for mating connection with the stator blade.

Embodiment 2

[0052] combine Figure 5-8 As shown, a method for preparing a draft tube of a gas turbine stator blade in a heat pump system comprises the following steps:

[0053] S1. Casting the guide tube of the gas turbine stator blade, comprising the following steps:

[0054] S11. Determine the size of the guide tube of the gas turbine stator blade;

[0055] S111. Determine the ring size S of the draft tube:

[0056] ,

[0057] in, Fixed parameters for the wall thickness of the diversion tube, usually 0.1mm-1.0mm; It is the variation parameter of the wall thickness of the draft tube, usually 0mm-5.0mm; is the casting allowance;

[0058] S112. Determine the end face dimension U of the draft tube:

[0059] ,

[0060] in, Fixed parameters for the wall thickness of the draft tube; is the variation parameter of the wall thickness of the draft tube; is the casting allowance;

[0061] S12. Make a casting mold: Make a casting mold according to the size S of the guide tube r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap