Analyzing and monitoring system for dynamic state abnormity of dragging construction of steel truss girder bridge

A monitoring system and dynamic state technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as difficult to meet the needs of high-efficiency and high-stability bridge construction, and achieve the effect of avoiding subsequent safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

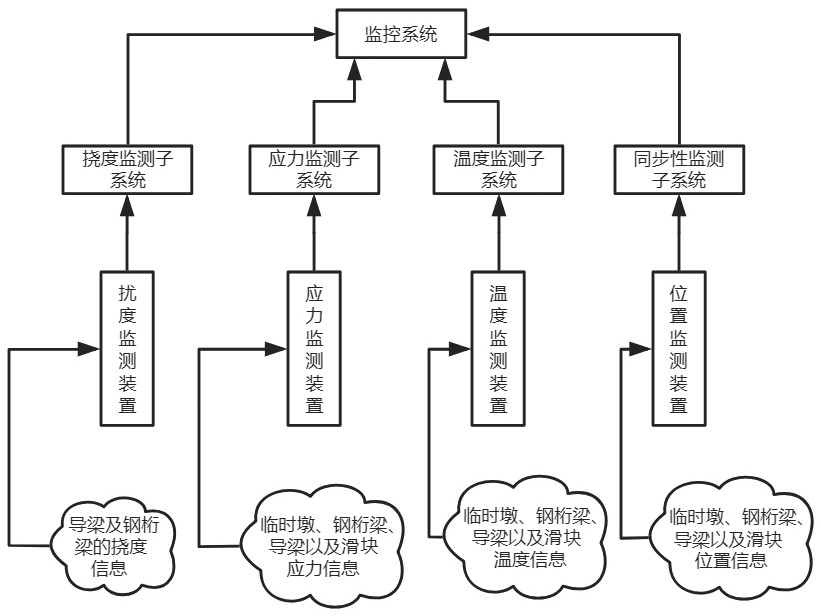

[0034] The monitoring system includes a deflection monitoring subsystem, a stress monitoring subsystem, a temperature monitoring subsystem and a synchronization monitoring subsystem. The monitoring system also includes a main processing control subsystem for collecting and analyzing monitoring data information of the above-mentioned subsystems.

[0035] Preset in the monitoring system:

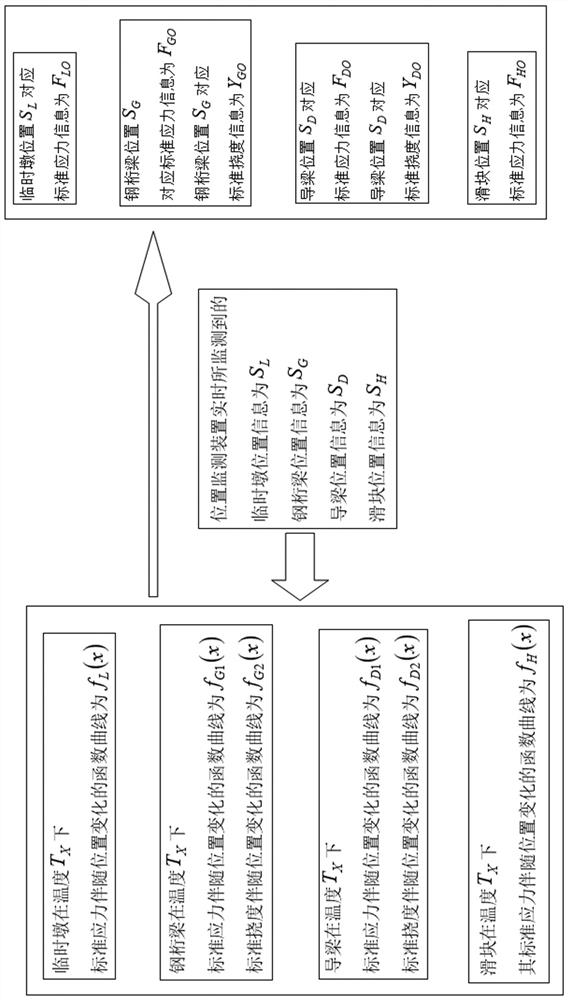

[0036] ①Temporary pier at temperature T X , the function curve of the standard stress along with the position change is f L (x); ②Steel truss girder at temperature T X , the function curve of the standard stress along with the position change is f G1 (x), the function curve of its standard deflection with position change is f G2 (x); ③ guide beam at temperature T X , the function curve of the standard stress along with the position change is f D1 (x), the function curve of its standard deflection with position change is f D2 (x); ④ slider at temperature T X , the function curve of the s...

Embodiment 2

[0041] The synchronization monitoring subsystem is connected with multiple position monitoring devices for data information, and the synchronization monitoring subsystem collects and analyzes the position information of temporary piers, steel truss girders, guide beams and sliders during the steel beam dragging into place process.

[0042] The temporary piers, steel truss girders, guide beams and sliders in the process of being dragged into place are all equipped with independent position monitoring devices, and the position information of the temporary piers monitored by the position monitoring device in real time is S L , the position information of the steel truss girder is S G , the position information of the guide beam is S D , the slider position information is S H .

[0043] The main processing control subsystem finds the position point monitored by the position monitoring device on the function curve of the standard stress or standard deflection of each structure, a...

Embodiment 3

[0051] The deflection monitoring subsystem is connected with multiple disturbance monitoring devices for data information, and the deflection monitoring subsystem collects and analyzes the deflection information of the guide beam and steel truss girder during the process of dragging the steel girder into place.

[0052] The stress monitoring subsystem is connected with multiple stress monitoring devices for data information, and the stress monitoring subsystem collects and analyzes the stress information of temporary piers, steel truss beams, guide beams and sliders in each state and position during the dragging process.

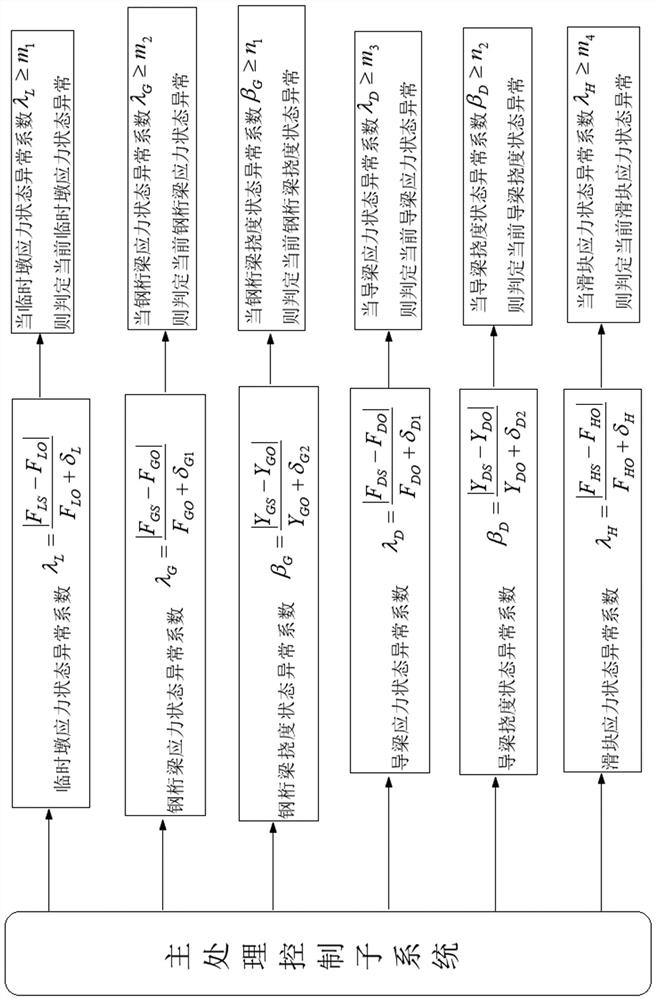

[0053] The main processing control subsystem obtains the actual stress or actual deflection of the real-time position of each structure:

[0054] ①Temporary pier position S L The actual monitored stress information is F LS ;

[0055] ②Steel truss position S G The actual monitored stress information is F GS , steel truss position S G The deflection infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com