Real ship slamming pressure peak forecasting method

A slamming, real ship technology, applied in the field of real ship slamming pressure peak prediction, can solve the problems of test measurement results distortion, small scale, unable to reflect the relative speed of waves and hulls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

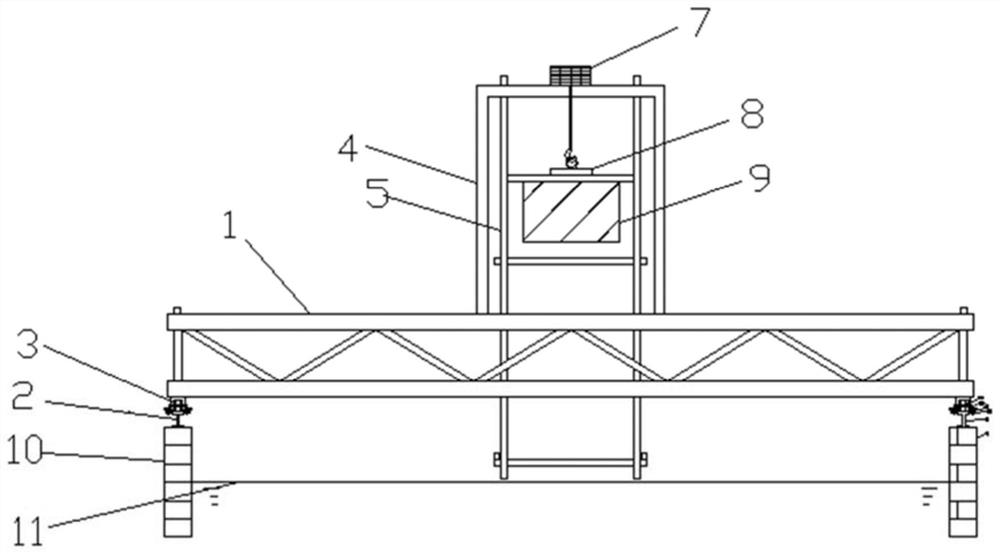

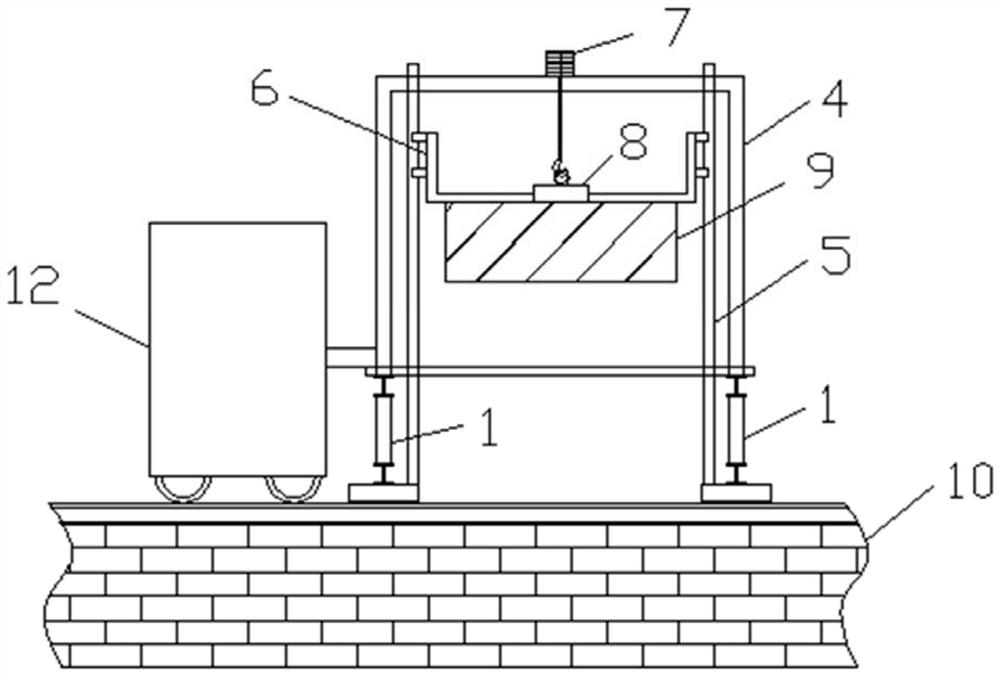

[0052] 1) The mobile drop test device is mainly composed of three parts: a mobile bracket, a sliding module and a lifting module. The mobile bracket is composed of a truss structure 1 across the pool and a rolling wheel 3 running along the track 2 of the towing pool. The specifications of the side and rolling wheels 3 are determined according to the guide rails of the pool; the sliding module is composed of an external steel strong frame 4, a built-in stainless steel rail 5 and a connecting member 6 that can slide on the rails. The steel strong frame 4 is processed sufficiently strong, generally Fastened by bolts, nuts and connecting angle irons, the connecting member 6 and the stainless steel rail 5 are connected by guide wheels to ensure that the sliding module can fall vertically along the stainless steel rail 5; the lifting module is composed of an electric crane 7 and an electromagnet 8, The electric hoist 7 is installed on the top of the strong frame 4, and the model can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com