Optical imaging lens

An optical imaging lens and imaging surface technology, applied in optics, optical components, instruments, etc., can solve the problem of unclear shooting of the details of the optical imaging lens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

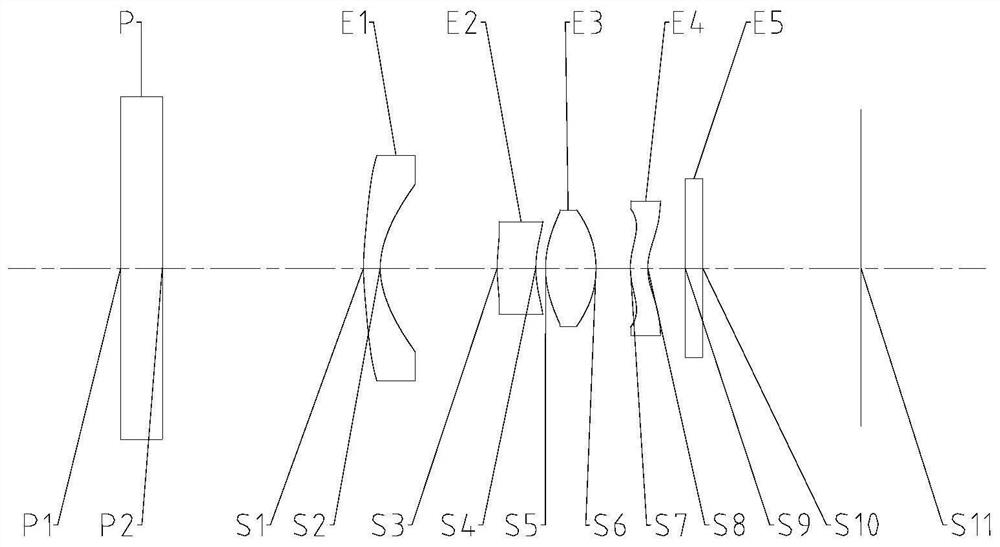

[0059] Such as Figure 1 to Figure 30 As shown, along the optical axis, from the object side of the optical imaging lens to the image side of the optical imaging lens, the plane glass, the first lens, the second lens, the third lens and the fourth lens are sequentially included; the image side of the first lens is a concave surface; The fourth lens has a negative refractive power; wherein, half the Semi-FOV of the maximum field of view of the optical imaging lens satisfies: Semi-FOV>40°; the effective focal length f1 of the first lens and the combination of the second lens and the third lens The focal length between f23 satisfies: -1.0<f23 / f1<-0.5.

[0060] By arranging plane glass on the object side of the first lens, the plane glass can protect the rear lens, and at the same time, the image side of the first lens is set as a concave surface, and the fourth lens is set as a negative refractive power, which can maintain light Under the premise of good convergence, the optical...

Embodiment 2

[0078] Such as Figure 1 to Figure 30 As shown, along the optical axis, from the object side of the optical imaging lens to the image side of the optical imaging lens, plane glass is sequentially included; a first lens, a second lens; a third lens and a fourth lens, and the image side of the first lens is a concave surface; The fourth lens has a negative refractive power; wherein, half the Semi-FOV of the maximum field of view of the optical imaging lens satisfies: Semi-FOV>40°; the air interval T12 between the first lens and the second lens on the optical axis and the optical When the imaging lens is in the minimum object distance state, the distance BFL1 between the image side of the fourth lens and the imaging surface of the optical imaging lens on the optical axis satisfies: 0<T12 / BFL1<1.0.

[0079] By arranging plane glass on the object side of the first lens, the plane glass can protect the rear lens, and at the same time, the image side of the first lens is set as a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com