Method and system for constructing mesoscopic model for performance prediction of composite materials

A technology for performance prediction and composite materials, applied in special data processing applications, instruments, design optimization/simulation, etc., can solve problems such as reduced modeling efficiency, contact definition, troublesome post-processing of expansion calculation, unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment 1 proposes a construction system for a mesoscopic model for performance prediction of composite materials, including: a determination module for determining the model space and boundaries; a calculation module for calculating particles in each size range according to a predetermined gradation The first model compression module is used to reduce the size of the particles located in the model space, and randomly obtain the compressed model of the particles in the size range that conforms to the predetermined gradation; the particles that intersect the boundary are generated according to the original size, not Generate a compressed model, and only keep the part in the model space; the expansion module is used to expand the area of the compressed model of each particle to obtain the expansion model of the compressed model of each particle; the second compression module is used to expand the expansion model of each particle. Area shrinkage is performed so th...

Embodiment 2

[0079] In Embodiment 2 of the present invention, taking a two-dimensional model as an example, an efficient modeling method for a high-density particle reinforced composite material is introduced and explained, and the method includes the following steps:

[0080] (1) Determine the boundary of the model space;

[0081] (2) Calculate the area sum of the particles in each size range according to the predetermined gradation and according to the formulas such as Wallaven, that is, determine the area sum S of the particles in the size range i to j (i~j) ;

[0082] (3) If the particle is located in the interior of the model space, reduce the size of the particle by α times (α(i~j) ×β, to ensure that there is no interference between particles, the compact model of each particle in the size range i to j can be obtained;

[0083] (4) If the particle intersects the boundary of the model space, the size of the randomly obtained particle model is in the range of i~j, and only the part in...

Embodiment 3

[0111] Embodiment 3 of the present invention provides a two-dimensional efficient modeling method for high-density particle-reinforced composite materials, comprising the following steps:

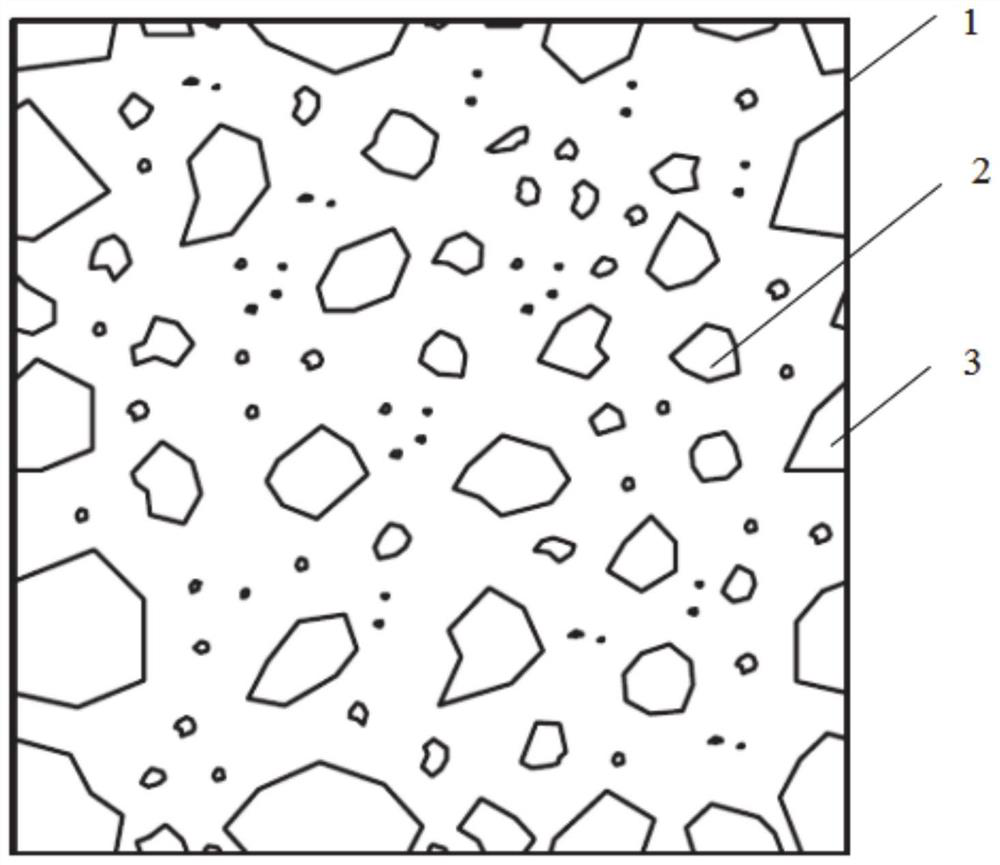

[0112] (1) Determine the boundary of the model space, such as figure 1 The model shown, 1 is the model boundary;

[0113] (2) According to the predetermined gradation, a compact model of the particles is generated, such as figure 1 Medium 2 is the particle compaction model, and the compacted particle size is 0.8 times its original size, that is, α=0.8;

[0114] (3) Divide the particles into two-dimensional solid units and assign them thermal elastic-plastic material properties;

[0115] (4) Divide the boundary of the model into two-dimensional solid elements and give them rigid material properties;

[0116] (5) Define the contact mode between particles and particles and between particles and boundaries as surface-surface contact mode;

[0117] (6) In the model space established in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com