Suspended painting system for vertical enamelling machine

A paint system and enameling machine technology, applied in electrical components, circuits, and conductor/cable insulation, etc., can solve problems such as insufficient eccentricity of paint layer, uneven paint layer thickness, and actual production problems, and achieve the improvement of jitter amplitude. , to ensure the effect of paint uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

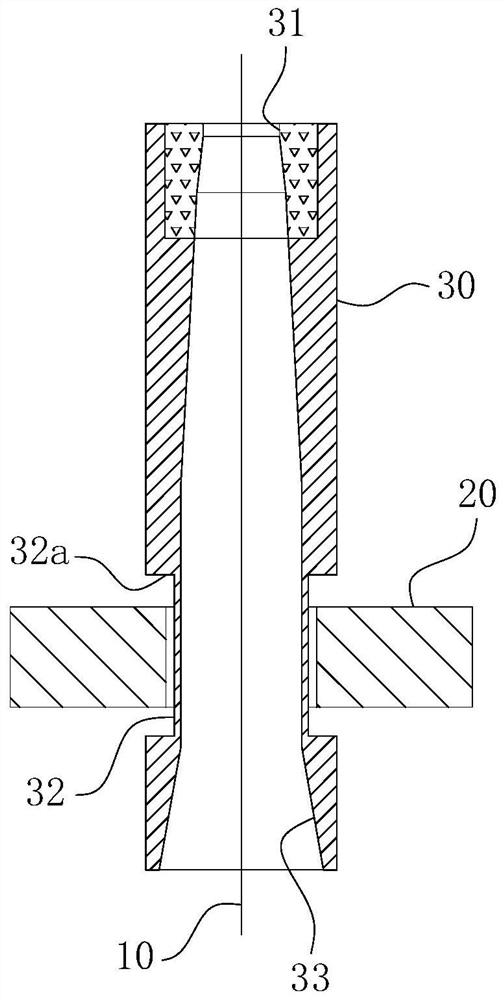

[0020] For ease of understanding, combined here Figure 2-3 Concrete implementation structure and workflow of the present invention are further elaborated as follows:

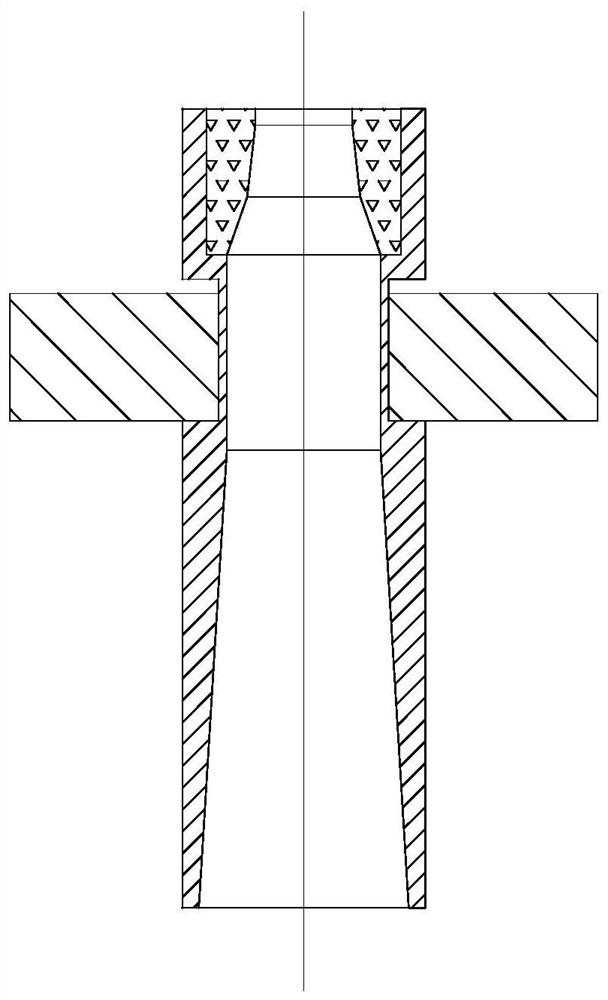

[0021] Specific embodiments of the present invention are constructed with reference to Figure 2-3 shown, which is similar to figure 1 The inverted state of the structure, that is, the presented and figure 1 The structure shown is the opposite of a top-heavy structure.

[0022] In actual design, such as figure 2 As shown, it also includes a sleeve-shaped body, and a snap ring 32 is arranged on the lower part of the body so as to facilitate snapping into the slot 21 of the fixed beam 20 . In order to ensure the radial movement limit of the enamelled mold 30, it may be considered to arrange an additional positioning beam, and fix the positioning beam to the notch of the card slot 21 through the insertion of the vertical pin.

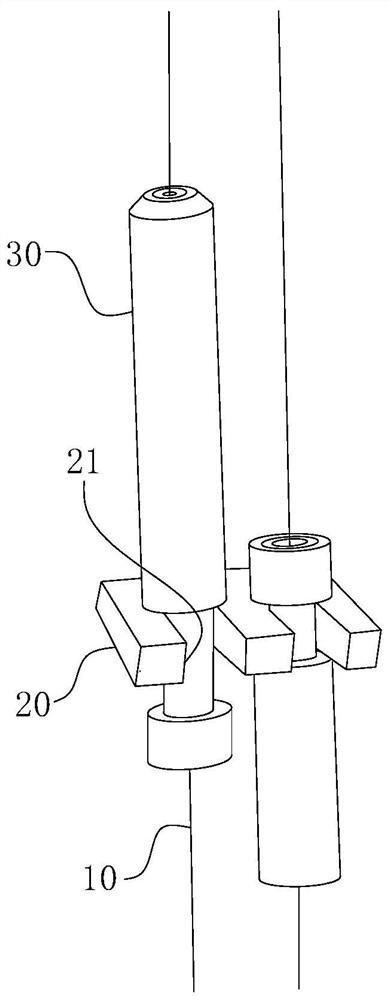

[0023] When the present invention works normally, wire a is as image 3 Shown fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com