Enameled wire painting device convenient for high-precision adjustment, and use method thereof

A technology of painting device and enameled wire, applied in the direction of insulating conductors/cables, etc., can solve the problems of non-concentric coating of insulating layer, unreasonable installation position, abrasion of painting molds, etc., to ensure the consistency of paint film and ensure coating The effect of paint uniformity and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

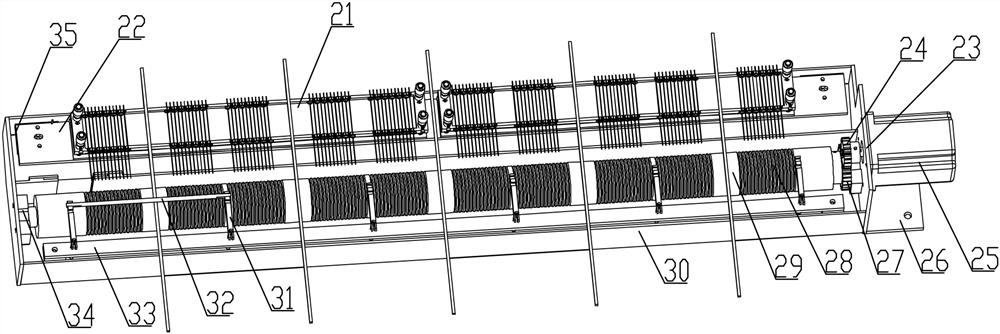

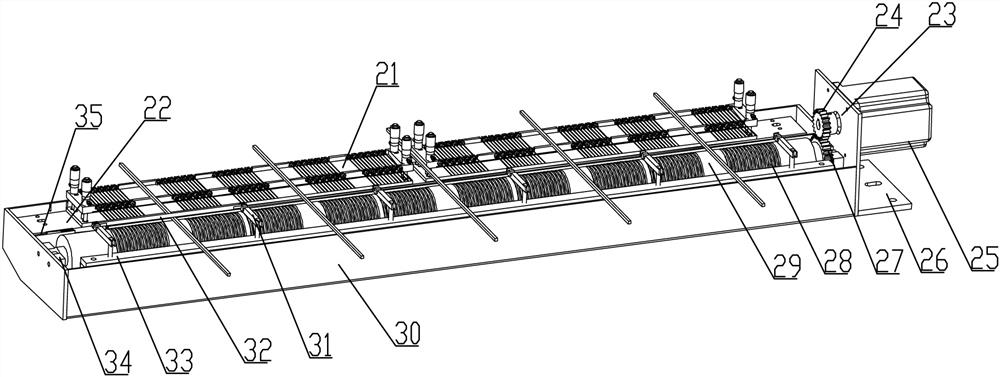

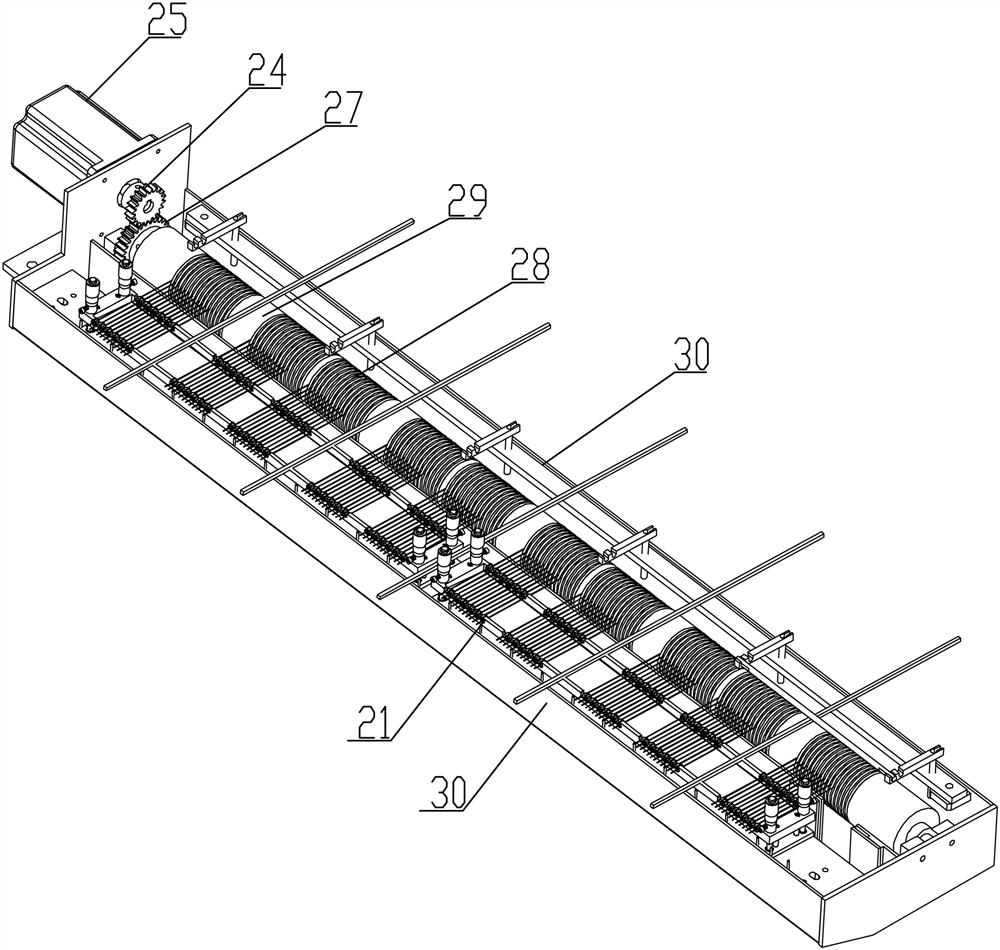

[0049] see Figure 1-11 , an enameled wire painting device that is convenient for high-precision adjustment, it includes a paint storage box 30 for holding insulating varnish, and one side of the inside of the paint storage box 30 is rotated and installed with a paint roller through a symmetrically arranged bearing seat 34 29. The paint roller 29 is processed with a groove 28 for accommodating insulating paint, and the paint roller 29 is connected with a power device for driving it to rotate; the other side of the paint storage box 30 passes through The lug plate 35 is supported by a horizontal plate 22, on which multiple groups of mold support structures 21 that can individually adjust the position of the painting mold are selectively installed on the horizontal plate 22 according to the needs of use; on the inner wall of the paint storage box 30, And a crossbeam 33 is fixed on the side where the paint roller 29 is located, and the limit rod 32 is supported by a support arm 3...

Embodiment 2

[0061] A method for using an enameled wire painting device that is convenient for high-precision adjustment includes the following steps:

[0062] Step 1, support and install the entire mold support structure 21 on the horizontal plate 22, and then install the entire painting device on the production line;

[0063] Step 2, passing the metal conductor 8 to be painted through the paint mold 10 on the paint mold support and the U-shaped groove 9 on the other side plate;

[0064] Step 3: Detect the position of the metal conductor 8 in the painting mold 10. When the center of the metal conductor 8 deviates from the center of the painting mold 10, selectively rotate the knobs of the differential head at the four corners to adjust the lifting sleeve 6, and then adjust the front, rear, left, and right heights of the mold mounting plate 13 to realize the coincidence of the central axis of the painting mold 10 with the central axis of the metal conductor 8, thereby ensuring the uniformi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com