Rotatable pin insulator

A pin-type insulator, insulator technology, applied in the direction of pin-type insulators, insulators, electrical components, etc., can solve the problems of no cable retraction and fastening, insulator clips can not be disassembled and installed, etc., to improve efficiency, The effect of improving usability and usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

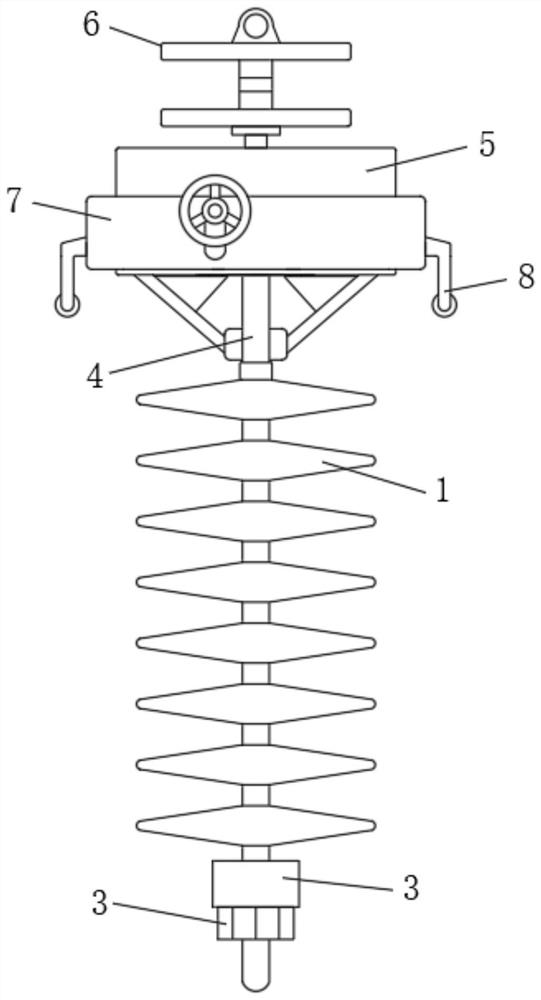

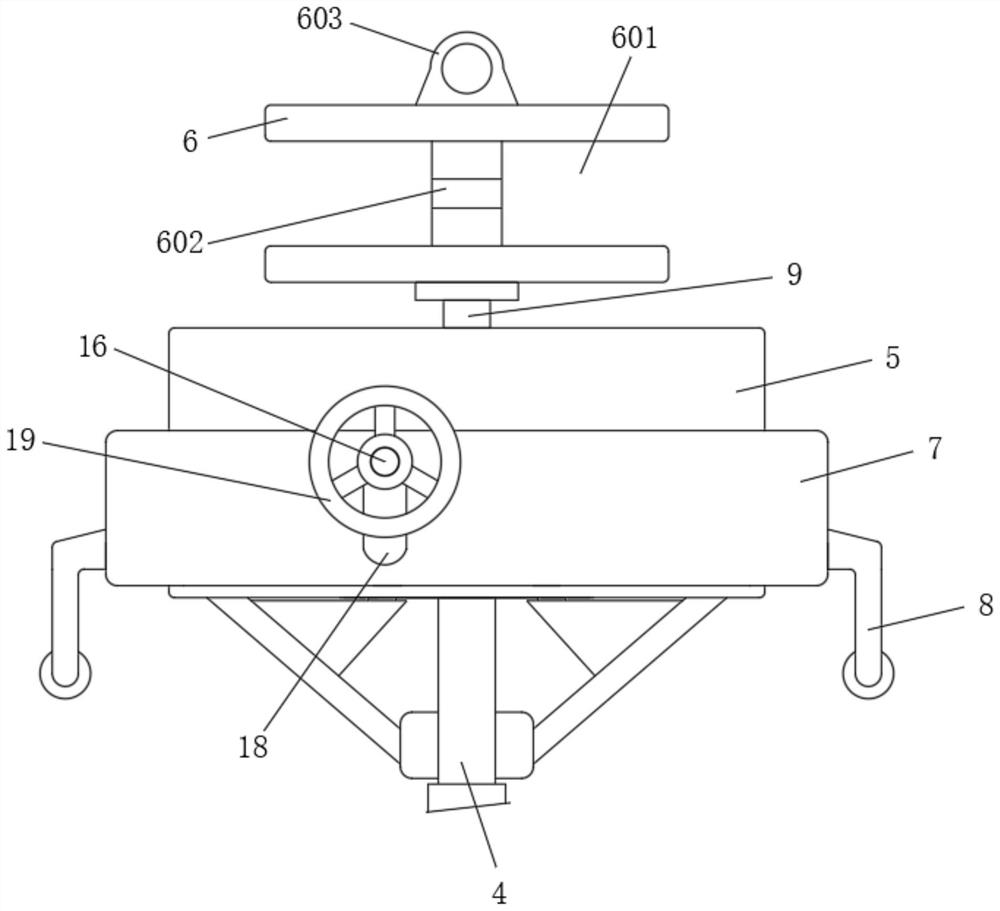

[0028] Embodiment one, by Figure 1 to Figure 4 Given, the present invention includes a pin insulator body 1, a connecting threaded pin 2 is installed on the bottom of the pin insulator body 1, a fixing nut 3 is connected to the surface of the connecting threaded pin 2, and a connecting rod 4 is installed on the top of the pin insulator body 1 , a fixed block 5 is installed on the top of the connecting rod 4, a cable reel 6 is installed on the top of the fixed block 5, a cover box 7 is installed on the surface of the fixed block 5, and an operating lever is fixedly installed on the bottom of both ends of the cover box 7 8;

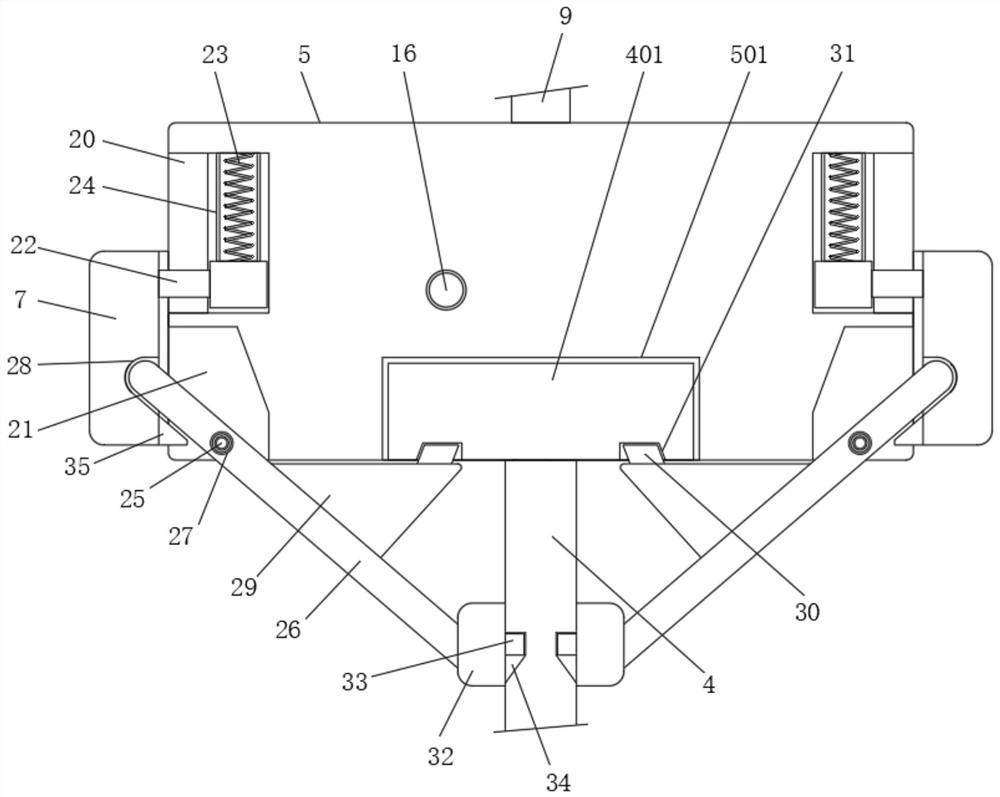

[0029] The top of the connecting rod 4 is fixedly connected with a block 401, and the middle part of the bottom of the fixed block 5 is provided with a groove 501, and the block 401 is snapped in the inside of the groove 501. By setting the block 401 and the groove 501, the fixed block 5. Can be installed stably and effectively;

[0030] The middle part ...

Embodiment 2

[0031] Embodiment two, on the basis of embodiment one, by Figure 4 Given, the surface of the rotating gear 11 is meshed with a fixed locking tooth 12, one end of the fixed locking tooth 12 is rotated and installed inside the adjustment cavity 10 through a fixed pin 13, and an extrusion plate 14 is fixedly installed on the upper part of the fixed locking tooth 12. A return spring 15 is installed between one side of the pressure plate 14 and the side wall of the adjustment cavity 10 , so that the fixed latch 12 can stably and effectively fix the rotating gear 11 .

Embodiment 3

[0032] Embodiment three, on the basis of embodiment two, by figure 2 , image 3 with Figure 4Given, the other side of the extrusion plate 14 is provided with a runner 17, and the circumferential surface of the runner 17 is equidistantly provided with extrusion bumps, and the ends of the extrusion bumps are in rolling contact with the other side of the extrusion plate 14. , the middle part of the runner 17 is rotatably equipped with a turn bar 16, and the turn bar 16 is rotatably installed in the inside of the adjustment chamber 10, so that the fixed latch 12 can be regulated so as to be separated from the turn gear 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com