A vent block structure with adjustable gap and die-casting mold containing it

A technology for die-casting molds and exhaust blocks, which is applied in the field of die-casting molds. It can solve the problems of restricting the use of exhaust blocks with valves, low reliability of mechanical devices, and low matching accuracy, so as to increase the efficiency of material/gas output and improve compatibility. and reliability, the effect of ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

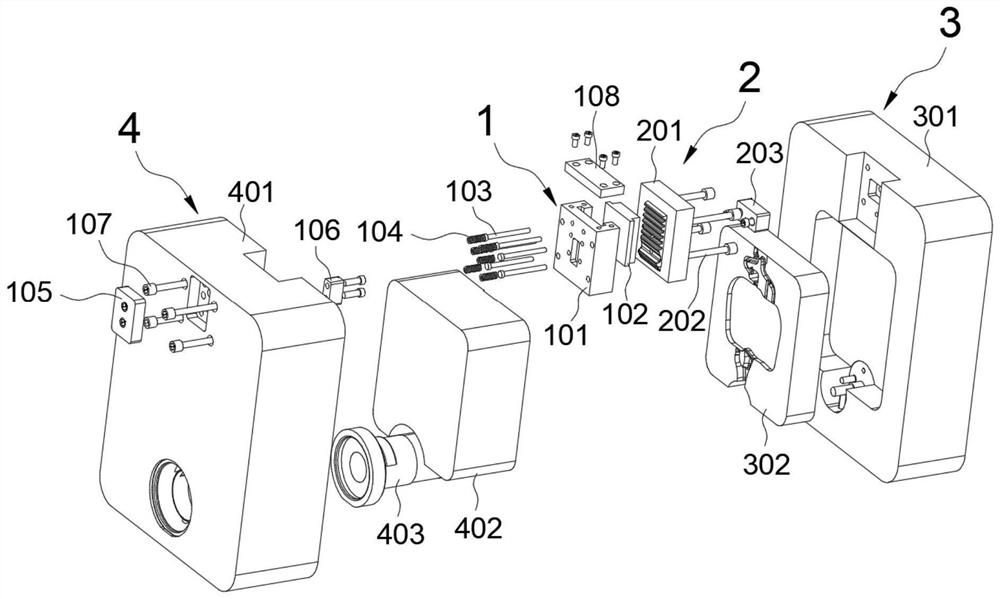

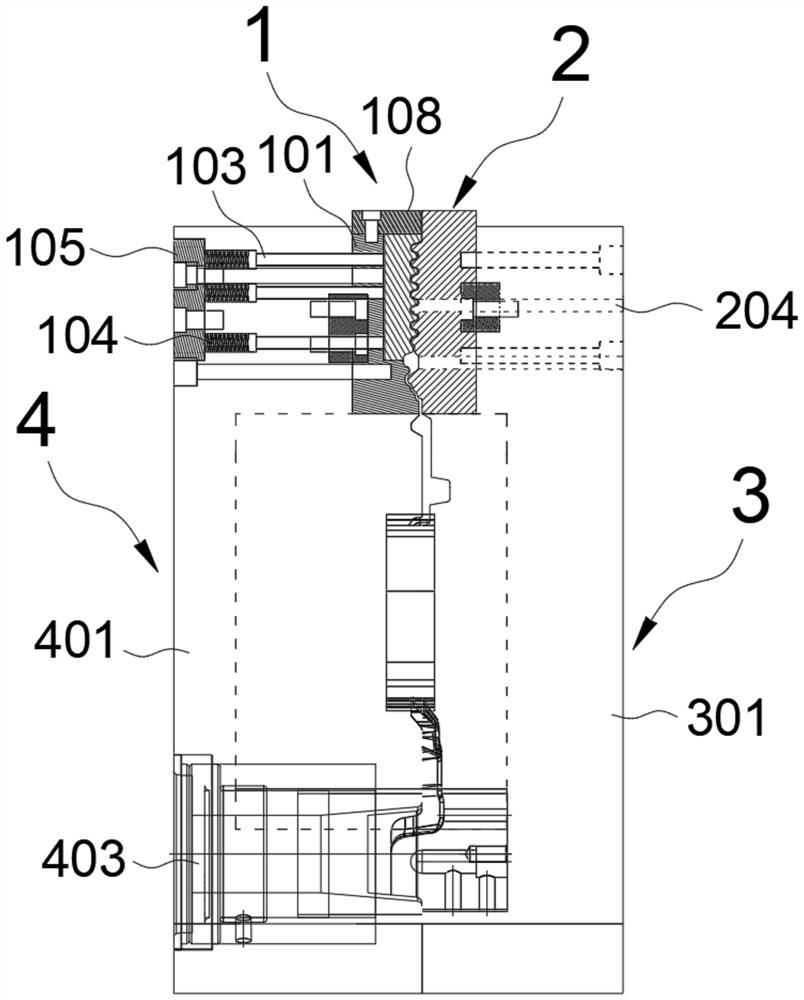

[0039] see figure 1 and figure 2 , the venting block structure with adjustable gap in the preferred embodiment of the present invention includes a first venting block assembly 1 and a second venting block assembly 2, and the two venting block assemblies are respectively arranged on the movable mold 3 and the fixed mold 4 After the movable mold 3 is matched with the fixed mold 4, the corresponding matching of the two exhaust block components can be completed, and an exhaust gap is formed between the two.

[0040] Specifically, in a preferred embodiment, the first exhaust block assembly 1 is arranged on the fixed mold 4 , and the second exhaust block assembly 2 is arranged on the movable mold 3 . Wherein, the first exhaust block assembly 1 includes the first exhaust block 101, the movable exhaust block 102 and the pre-top elastic member, and the first exhaust block 101 is provided with an accommodating groove corresponding to the movable exhaust block 102. The groove communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com