Improved high-speed cooking range

An improved, high-speed technology, applied in household stoves/stoves, household stoves, combustion types, etc., can solve the problems of easy flame injury, high stove temperature, natural gas waste, etc., to achieve fast heating speed and low energy consumption , strong practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

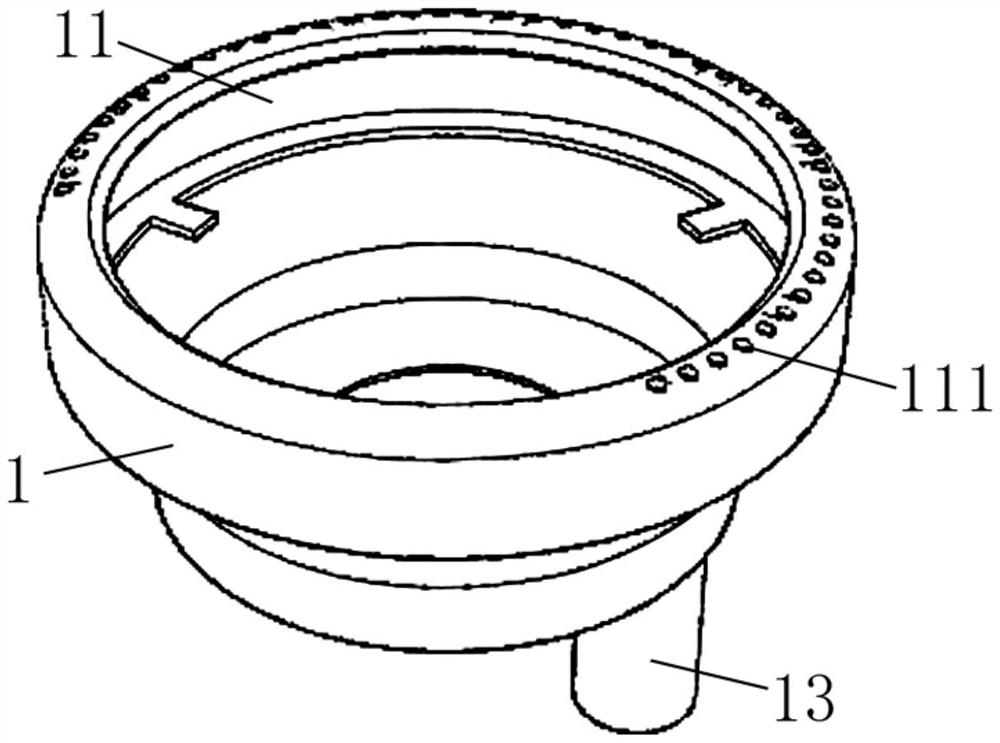

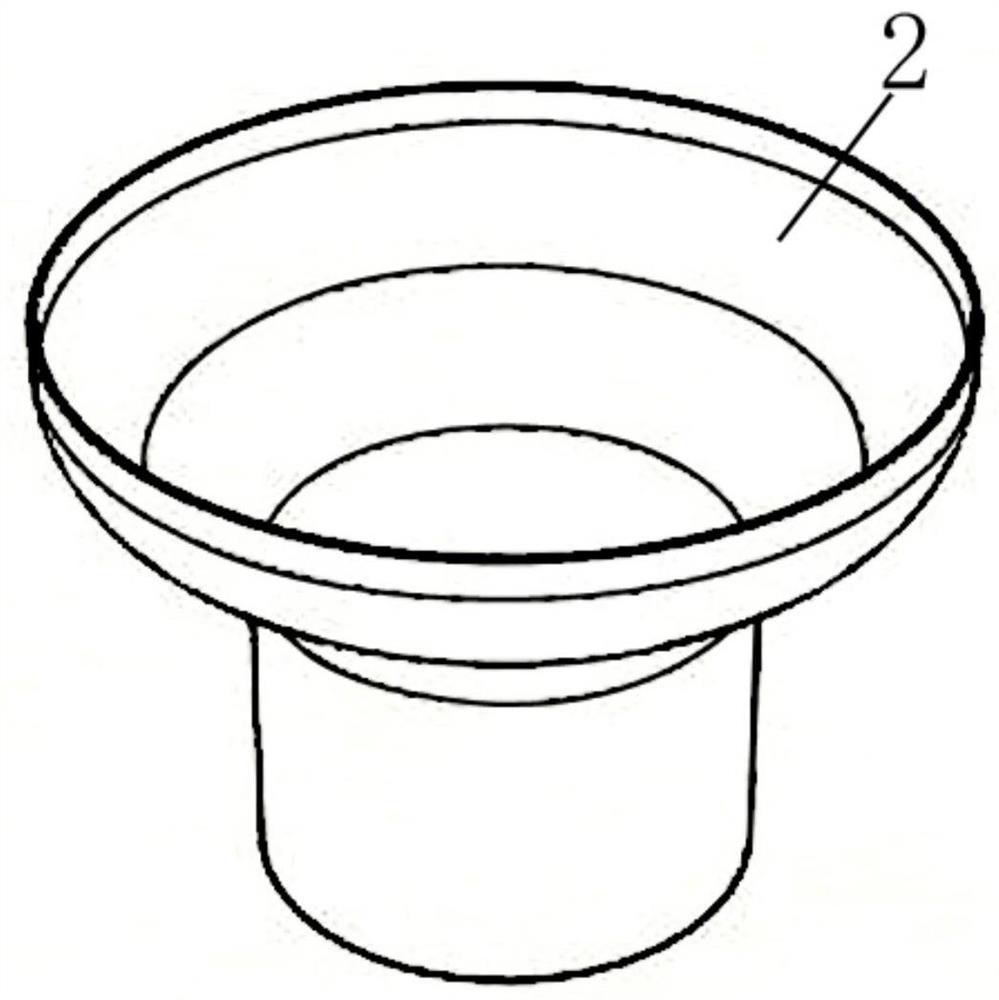

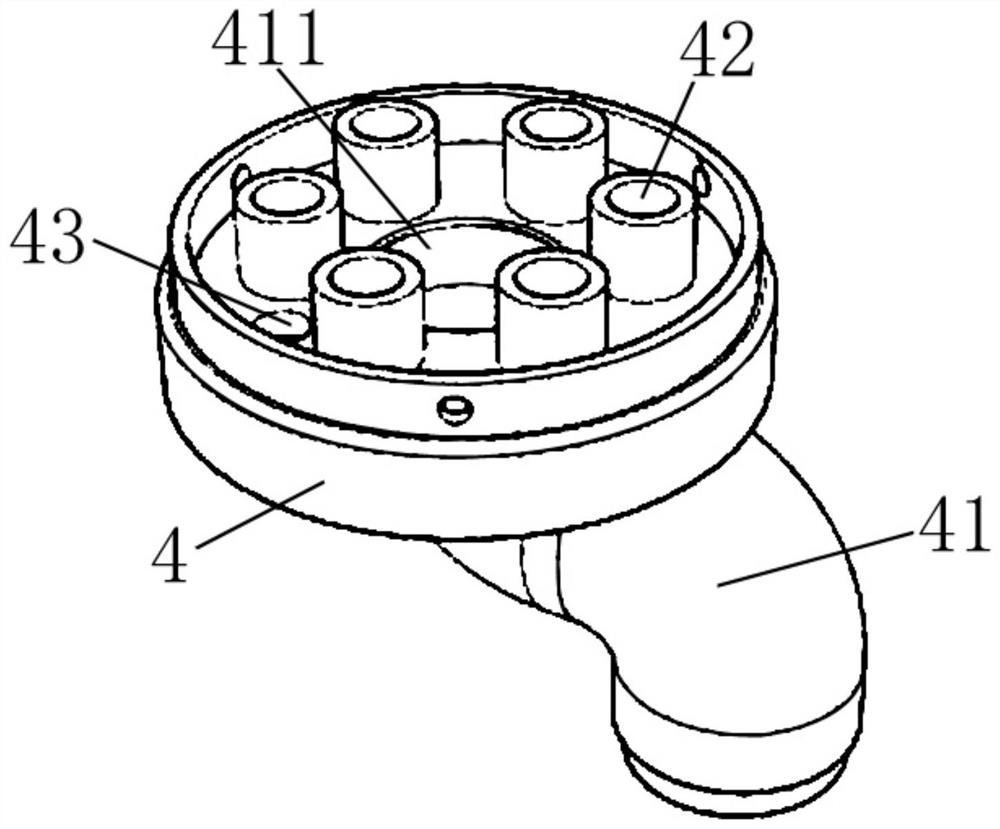

[0049] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an improved high-speed stove, which is composed of a round basin type return seat 1, a round basin type support seat 2, a spray gun type heating furnace seat, an air intake base 4, and a blower, is characterized in that,

[0050] The top edge of the round basin-type return seat 1 is bent inwards to form a circle of fire-blocking return flow grooves 11, and a plurality of circular pressure relief through holes 111 are drilled downward from the top surface of the round basin-type return seat 1;

[0051] The top surface of the round basin type return seat 1 is open, the middle part of the bottom surface of the round basin type return seat 1 is integrally formed with a circular through hole, and the bottom surface of the round basin type return seat 1 is also integrally formed with a vertical return pipe 13. The upper nozzle 411 of the return pipe 13 is located at the side of the circular through ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap