Atomized liquid drop coalescence simulation method in whole shaft

A simulation method and technology in the wellbore, applied in design optimization/simulation, instrumentation, electrical digital data processing, etc., to achieve the effects of ensuring accuracy, improving calculation accuracy, and facilitating timely adjustment of the simulation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

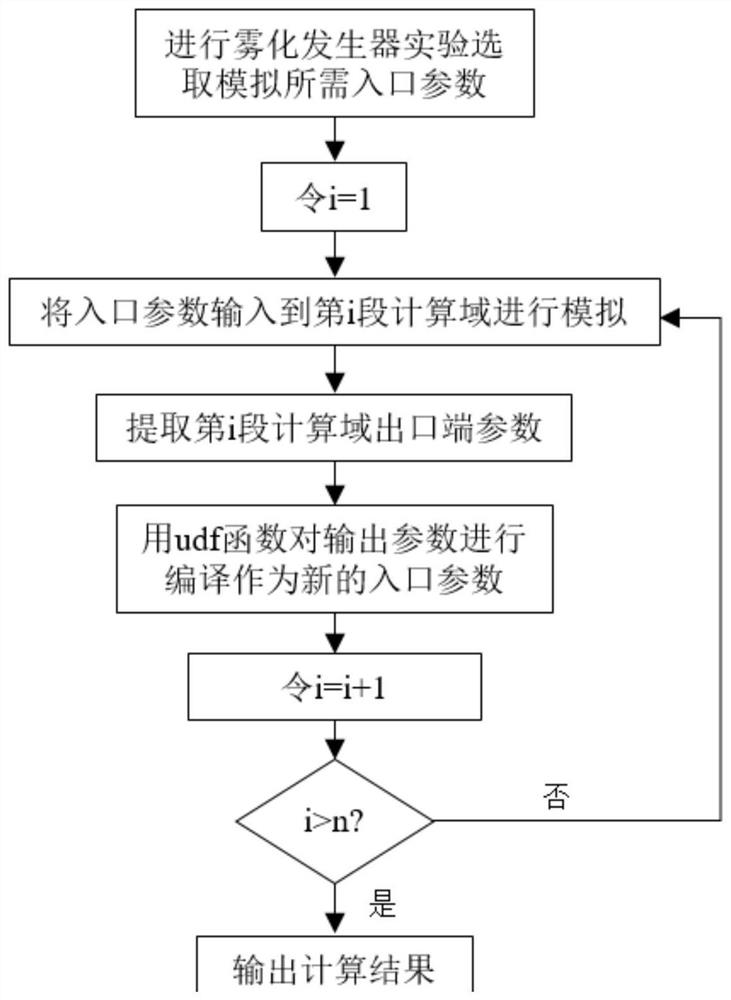

[0034] A method for merging and simulating atomized liquid droplets in a full wellbore, comprising the following steps:

[0035] S1: Through the atomization generator experiment, obtain the gas-liquid parameters corresponding to the optimal atomization rate under the experimental conditions, including the gas inlet flow rate v g , Liquid inlet velocity v l , gas-liquid volume ratio V, gas density ρ g , acid liquid density ρ l , gas viscosity μ g , acid viscosity μ l , injection pressure P 0 , inlet temperature T, droplet size D, surface tension σ. The parameters optimized by the experiment are used as the initial conditions of the numerical simulation, and the specific parameters are shown in Table 1.

[0036] Table 1 parameter setting table

[0037]

[0038]

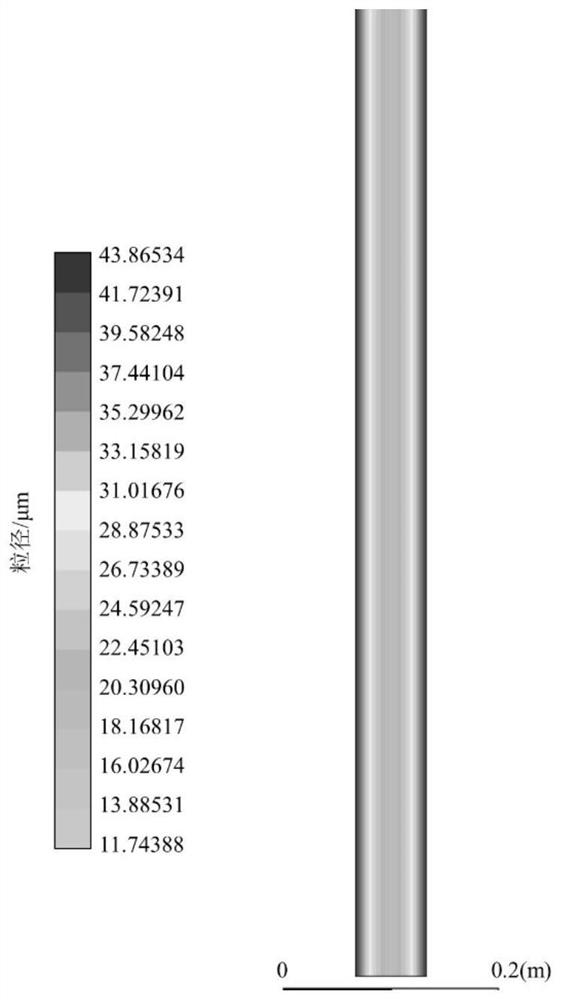

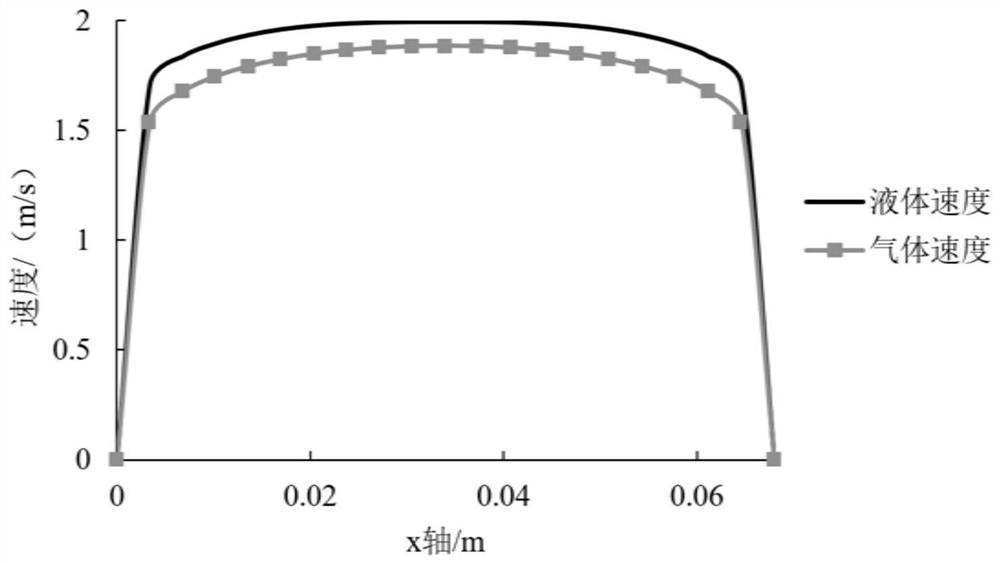

[0039] S2: Based on the gas-liquid parameters in S1, the flow model and droplet size change model of the atomized acid in the wellbore are given; after the acid liquid and gas are atomized at the wellhead, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com