Antenna assembly and mobile terminal

An antenna assembly and antenna technology, which is applied to antenna parts, antennas, antenna grounding devices, etc., can solve the problems of poor PIM performance at the connection point, and achieve the effects of low interface resistivity, low cost, and simple combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

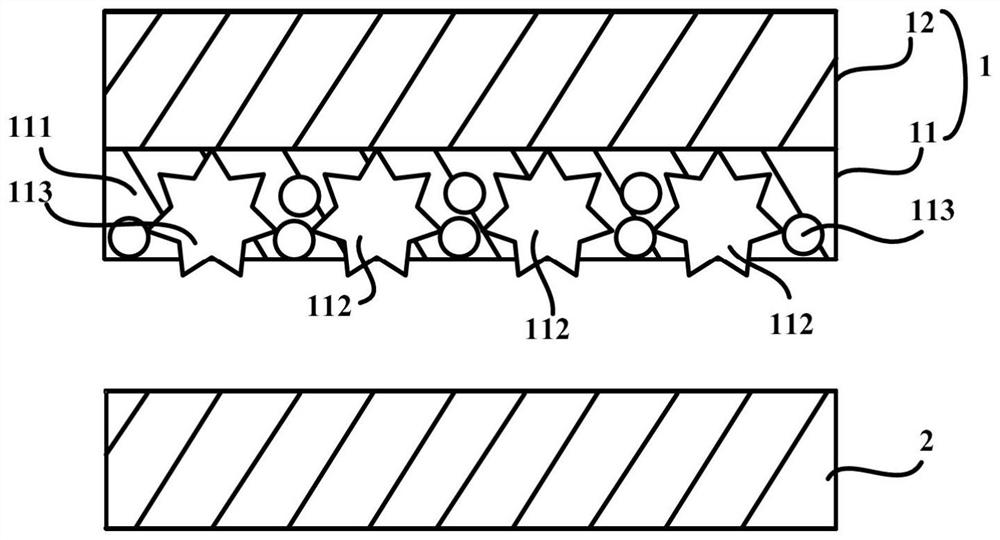

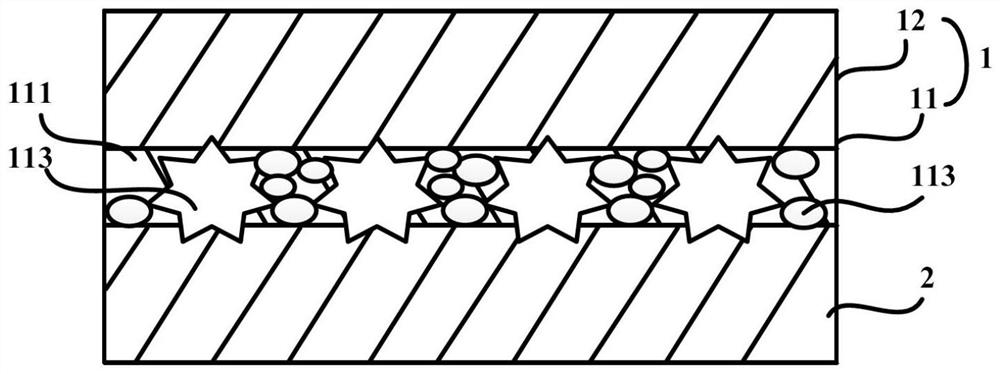

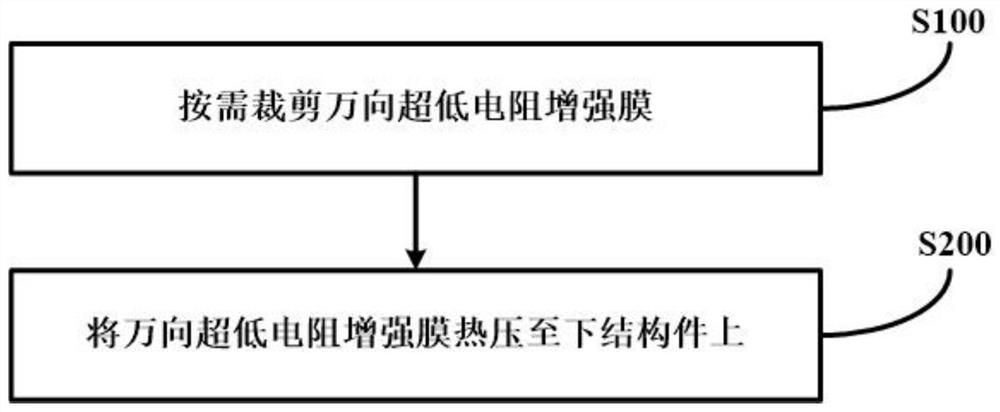

[0084] In the first embodiment, in the antenna grounding point in the antenna assembly, the universal ultra-low resistance enhancement film needs to be hot-pressed on the metal middle frame or metal middle plate (ie, the lower structural member) of the mobile terminal, so as to realize the contact of the antenna. interconnection of points. Among them, the material of the upper structural member of the universal ultra-low resistance enhancement film is selected as copper with gold plating on the surface, and the universal conductive adhesive applied on the surface of the upper structural member is required not to bring a large resistivity, and the lower the resistivity is. The better, the stronger the PIM performance, the better, and the universal conductive adhesive is required to be resistant to high temperature and have strong bonding force.

[0085]The mass percentage of each component in the universal conductive adhesive is: the mass percentage of the resin matrix is 70%...

Embodiment 2

[0094] The difference between the second embodiment and the first embodiment is that different hot pressing conditions are used in this embodiment than those in the first embodiment. In this embodiment, the first preset condition is: the pressure is 80N and the temperature is 90°C for 10s. The second preset condition is: keeping the pressure at 150N and the temperature at 200°C for 60s. The resulting resistivity is 12-24 milliohms.

[0095] In other embodiments, the hot pressing conditions can be changed, the structure, material, size and content of the conductive particles can be changed, and the material, size and content of the conductive filler can be changed, and the material of the resin matrix can also be changed. Resistivity, the lowest resistivity can reach 1-2 milliohms, and the change in resistivity will also bring about changes in PIM performance. It is not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com