Metal rib material and non-metal rib material connecting device and method

A connecting device, a non-metallic technology, applied in the connection of rods, connecting components, buildings, etc., can solve the problems of complex structure, unfavorable application promotion, unsuitable for permanent structures, etc., and achieve the effect of simple structure and reliable anchoring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

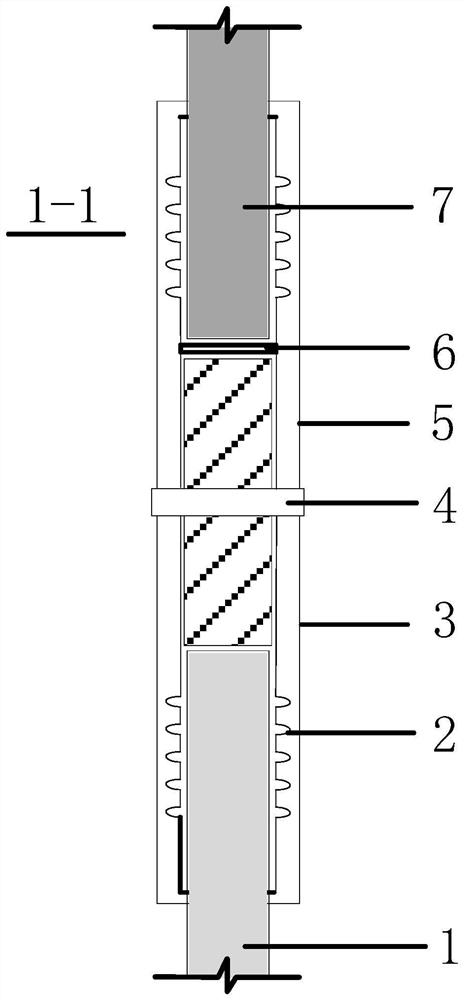

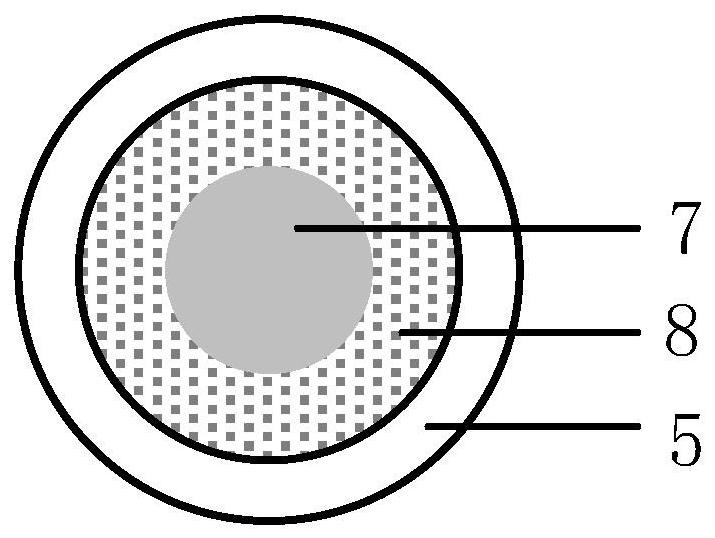

[0020] The main structure of the connecting device between metal and non-metal bars in this embodiment includes non-metal bars 1, annular groove 2, first connecting sleeve 3, two-way nut 4, second connecting sleeve 5, rubber pad 6 and metal Rib 7; the first connecting sleeve 3 and the second connecting sleeve are respectively set on the ends of the non-metallic rib 1 and the metal rib 7, the first connecting sleeve 3 and the second protecting sleeve are connected by a two-way nut 4, and the first connecting sleeve 3 and the second connecting casing are provided with threads on the inner wall close to the two-way nut 4, and the remaining part of the inner wall is distributed with annular grooves 2, and epoxy resin 8 is injected in the annular groove 2, so that the first connecting casing 3 and the non-metallic The rib 1, the second connecting casing 5 and the metal rib 7 are tightly fitted, and the rubber pad 6 is arranged at the junction of the thread and the annular groove on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com