Shadow maske frame assembly for color cathode ray tube

A cathode ray tube and shadow mask technology, applied in the field of color cathode ray tubes, can solve the problems of limited compensation for the expansion of the shadow mask plate 21a, high cost, and complicated manufacturing of shadow mask frame components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

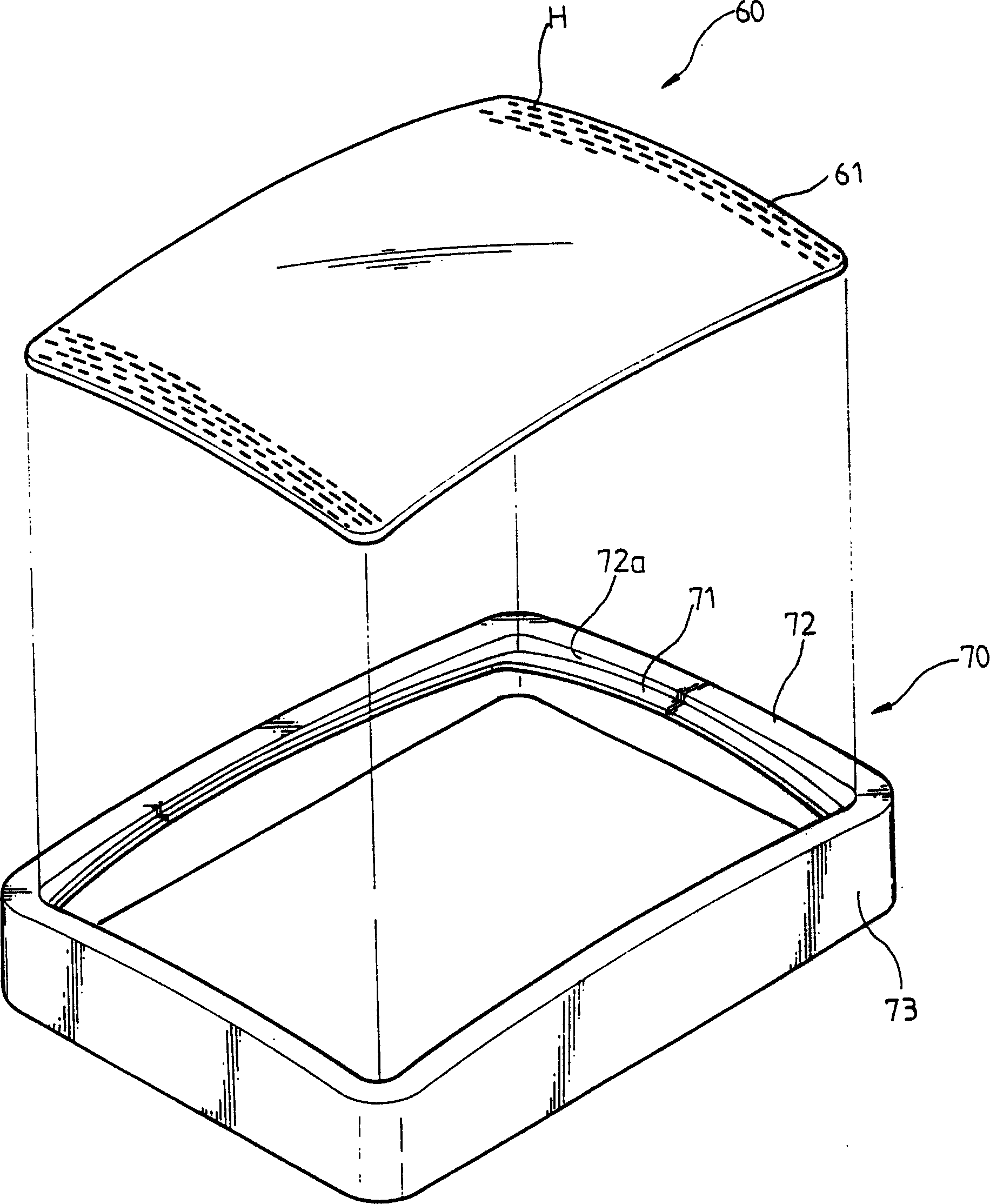

[0017] Refer to image 3 with Figure 4 , The shadow mask frame assembly includes a shadow mask 60 and a frame 70 that are coupled to each other. The shadow mask 60 on which a plurality of electron beam through holes H are formed is a plate having a predetermined curvature. With conventional shadow mask 21 ( figure 2 ) Is different. In the shadow mask 60 according to the present invention, the side edge part ( figure 2 21c).

[0018] The shadow mask 60 may have different curvatures in diagonal and horizontal / vertical directions. Compared to a flat panel, the radius of curvature of the shadow mask 60 is preferably made larger.

[0019] The frame 70 includes a flange 72 extending inward from the side wall 73 and having a predetermined curvature, and a support portion 71 extending from the flange 72 and having a curvature corresponding to the shadow mask 60.

[0020] The radius of curvature of the support portion 71 is smaller than the radius of curvature of the flange 72. The suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com