exhaust elbow

A technology of exhaust elbow and exhaust port, which is applied in exhaust treatment, exhaust device, muffler device, etc., to achieve the effect of reliable and simple method, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

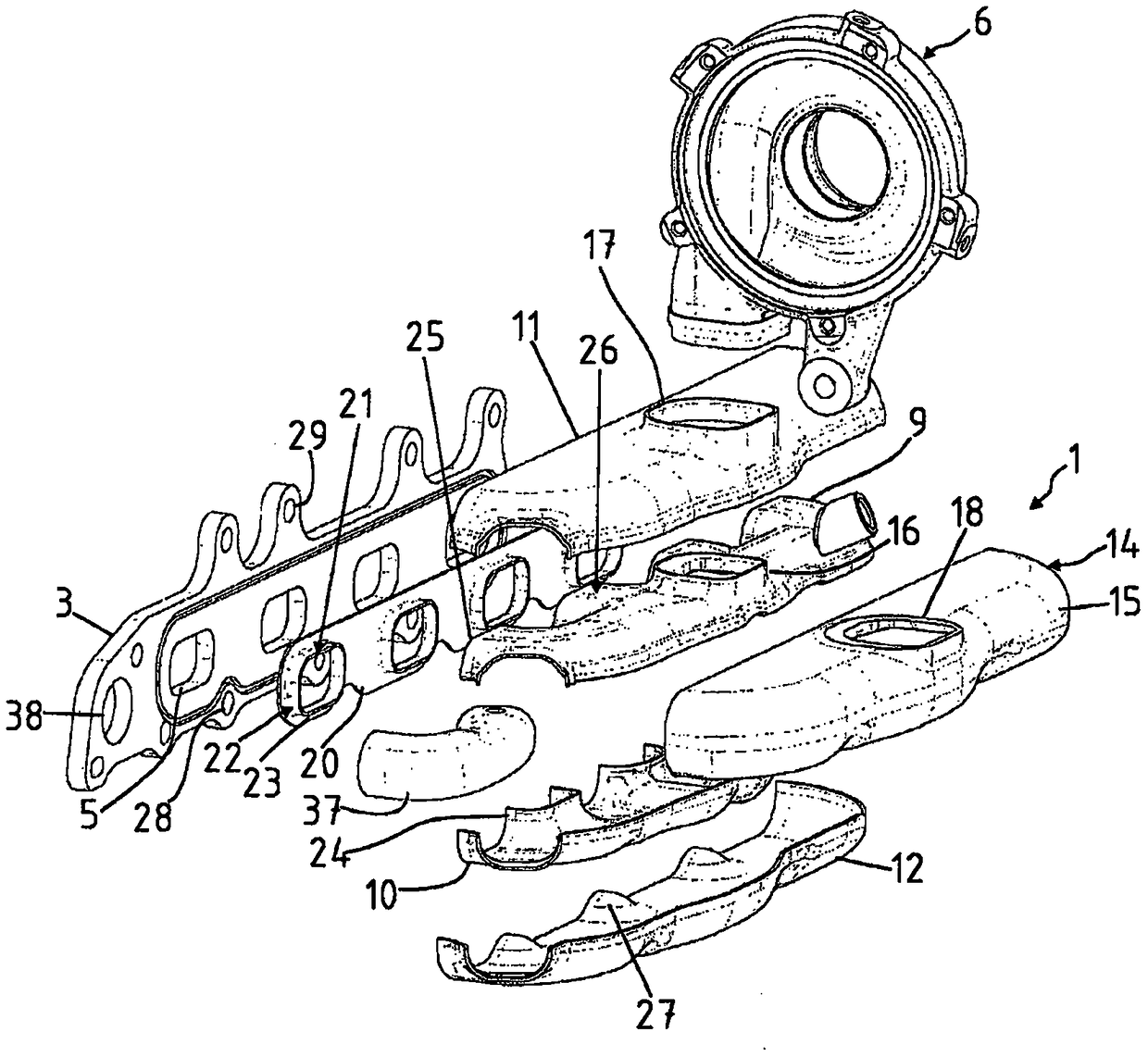

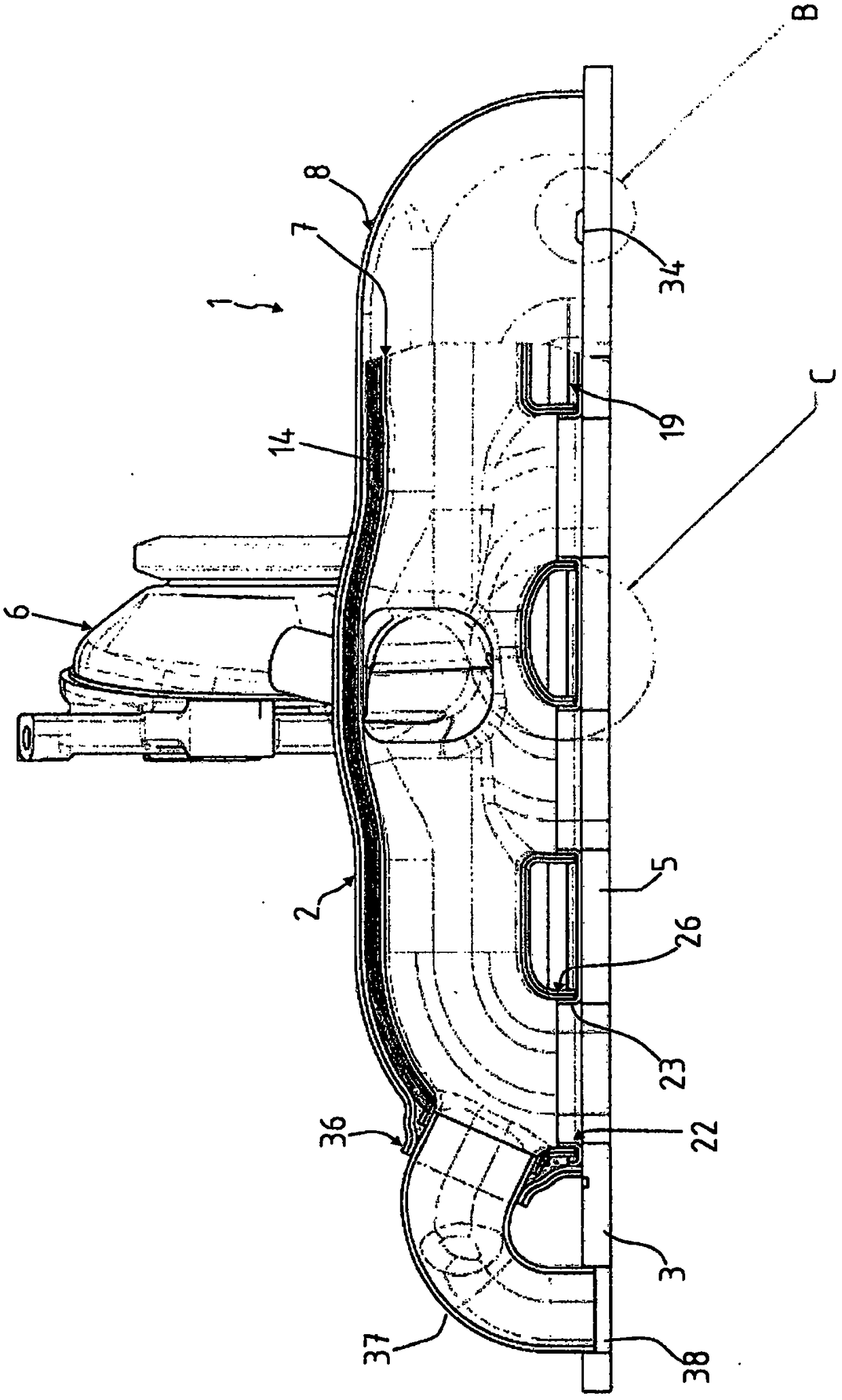

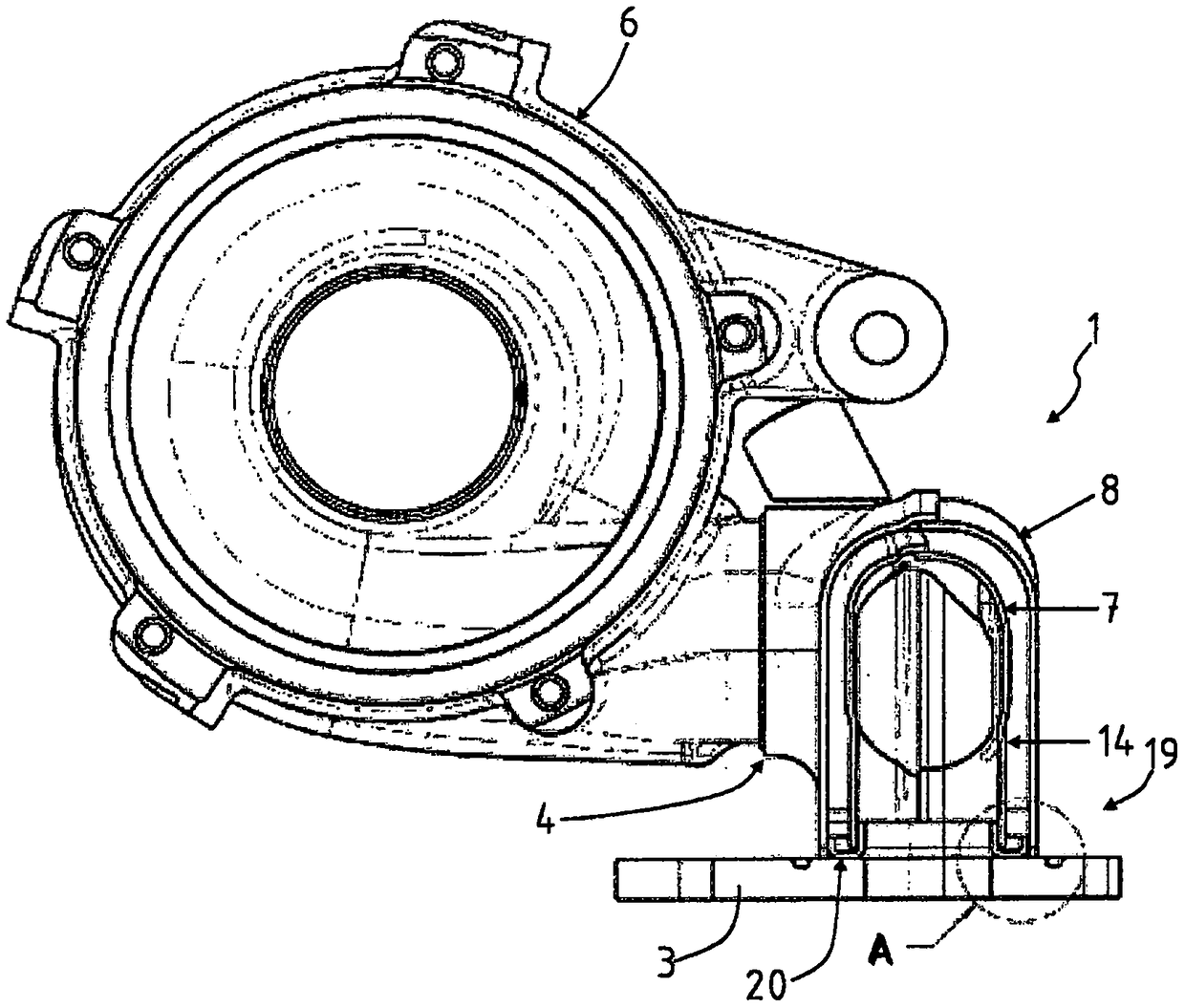

[0032] With the help of figure 1 The view of -6 presents an exhaust manifold 1 according to the invention of an exhaust system of an internal combustion engine. Figure 7 A variant of the exhaust manifold 1 is shown. The exhaust manifold 1 can be fastened to a cylinder head (not shown here) of a motor vehicle internal combustion engine.

[0033] The exhaust elbow 1 comprises a housing 2 with an inlet flange 3 and an exhaust hole 4 . The exhaust manifold 1 is attached via the intake flange 3 to the cylinder head of the internal combustion engine. The intake flange 3 has a plurality of intake openings 5 , via which the exhaust gases from the individual cylinders are diverted into the exhaust manifold 1 . The exhaust gas is conveyed via the exhaust opening 4 to a downstream component of the exhaust system, for example an exhaust gas turbocharger 6 as shown here.

[0034]The housing 2 comprises an inner shell 7 and an outer shell 8 . The inner shell 7 consists of two shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com