Warp knitting machine

A warp knitting machine and frame technology, applied in the field of warp knitting machines, can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

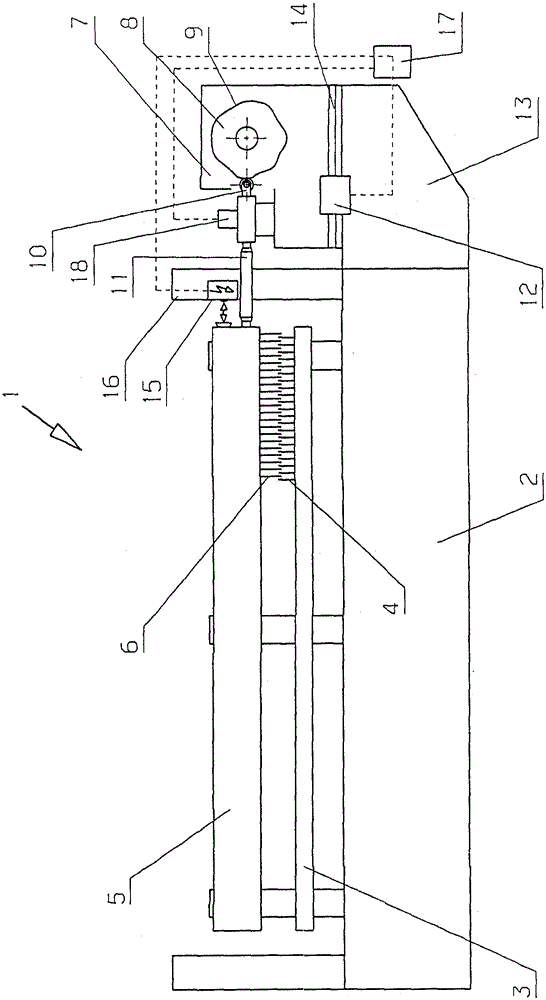

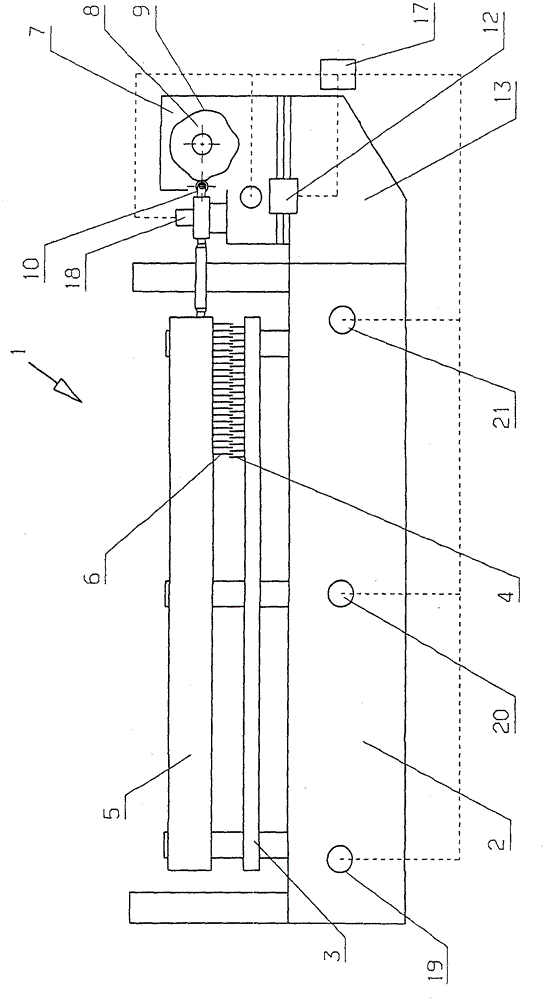

[0031] figure 1 In very schematic form, a warp knitting machine 1 is shown with a frame 2 carrying a needle bed 3 on which needles 4 are arranged side by side. Arranged in the frame 2 is a spindle, not shown in detail, which moves a needle bed 3 (shown in simplified form) upwards and downwards.

[0032] The frame 2 also carries the bar 5 on which the guide needle 6 is arranged. Drive the bar 5 via the main shaft in a manner known per se, so that the guide needle 6 is perpendicular to the drawing plane (relating to figure 1 icon) swing. Here, the bar 6 passes through the gaps between the knitting needles 4 .

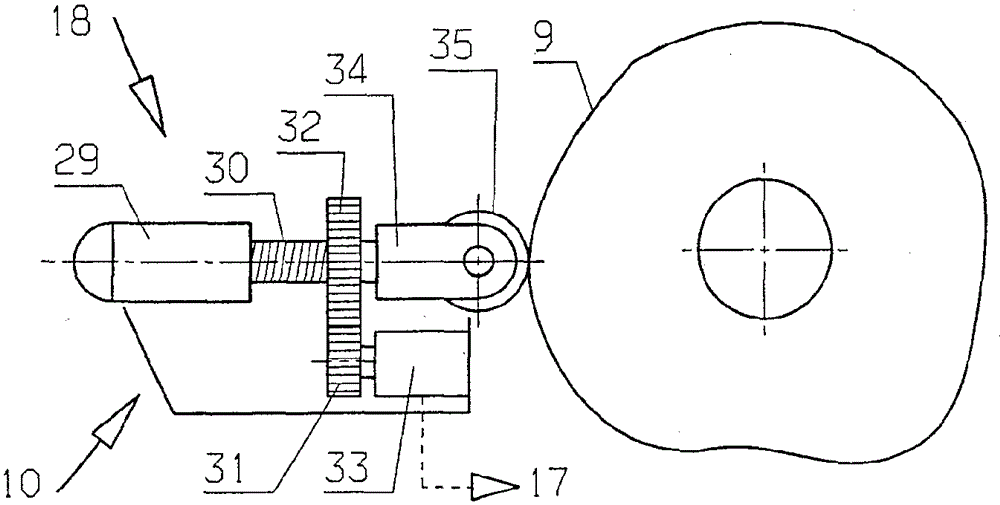

[0033] Arranged at the end of the machine frame 2 is a jacquard device 7 , which in the present case has a cam disc 8 . The cam disc 8 has a control surface 9 at its periphery. A displacement slide 10 acts as a transmission element on the control surface 9 , which acts on the bar 5 via a push rod 11 and drives the bar 5 in the mentioned displacement direction. The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com