PE plastic particle treatment method

A technology of plastic particles and processing methods, applied in the direction of packaging objects, packaging, and variable-capacity containers under special gas conditions, can solve problems such as friction, damage to the quality of PE plastic particles, damage to containers, etc., to prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

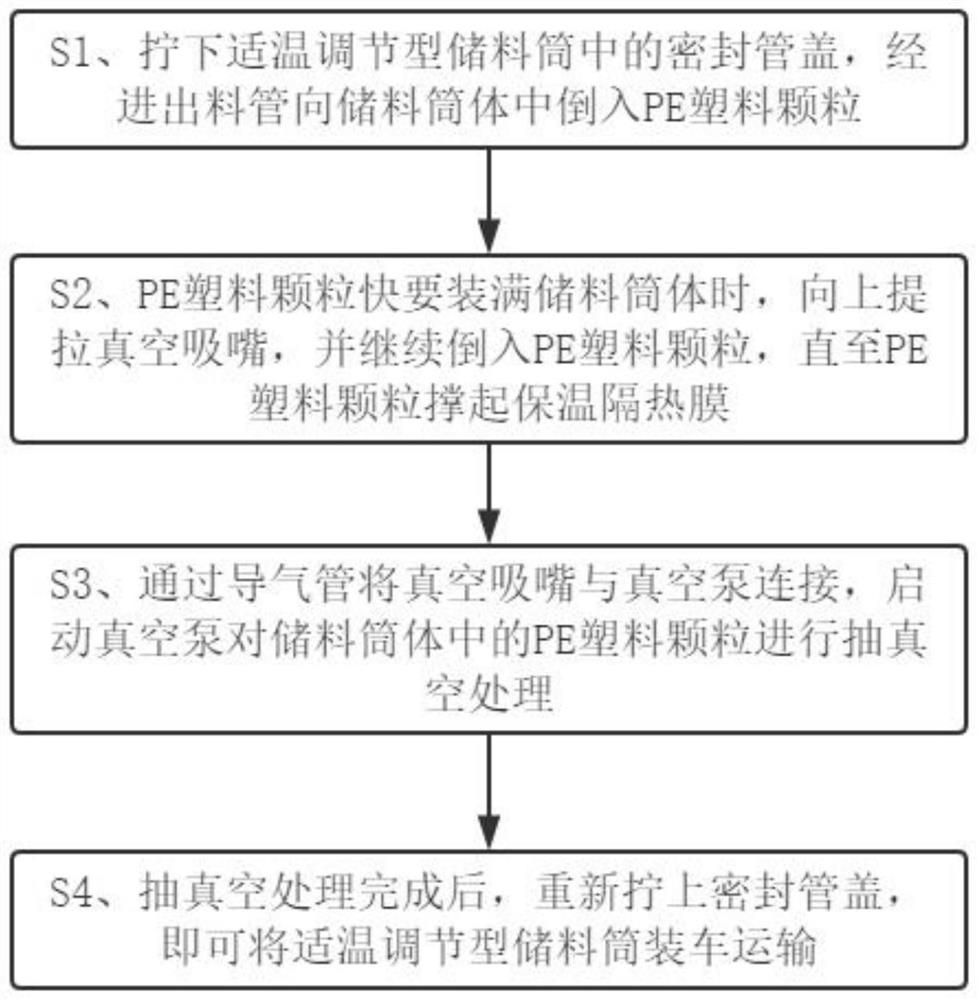

[0047] see Figure 1-8 , a PE plastic particle processing method, comprises the following steps:

[0048] S1. Unscrew the sealing tube cover 103 in the temperature-adjustable storage tank, and pour PE plastic particles into the storage tank 101 through the inlet and outlet tube 102;

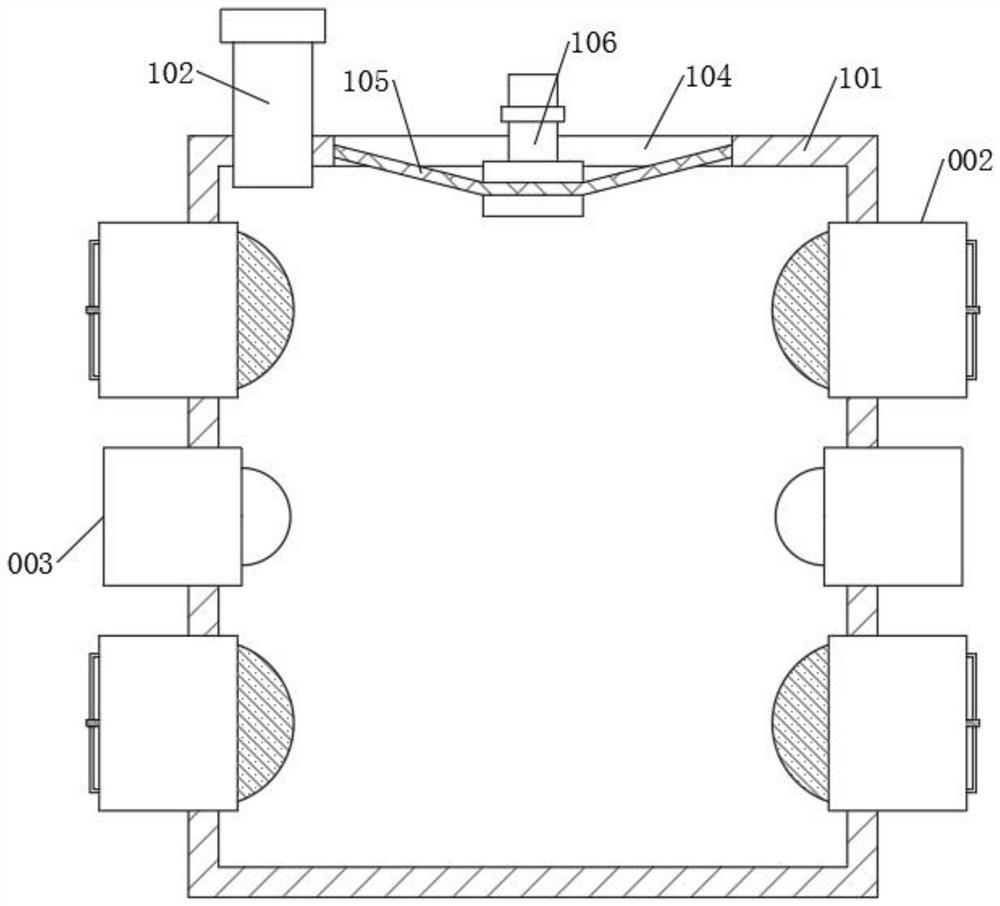

[0049] S2. When the PE plastic particles are about to fill the storage cylinder 101, pull up the vacuum nozzle 106, and continue to pour in the PE plastic particles until the PE plastic particles prop up the thermal insulation film 105;

[0050] S3. Connect the vacuum nozzle 106 to the vacuum pump through the air guide tube, and start the vacuum pump to vacuumize the PE plastic particles in the storage cylinder 101;

[0051] S4. After the vacuuming treatment is completed, the sealing tube cover 103 is re-screwed, and the temperature-adjusting storage tank can be loaded and transported.

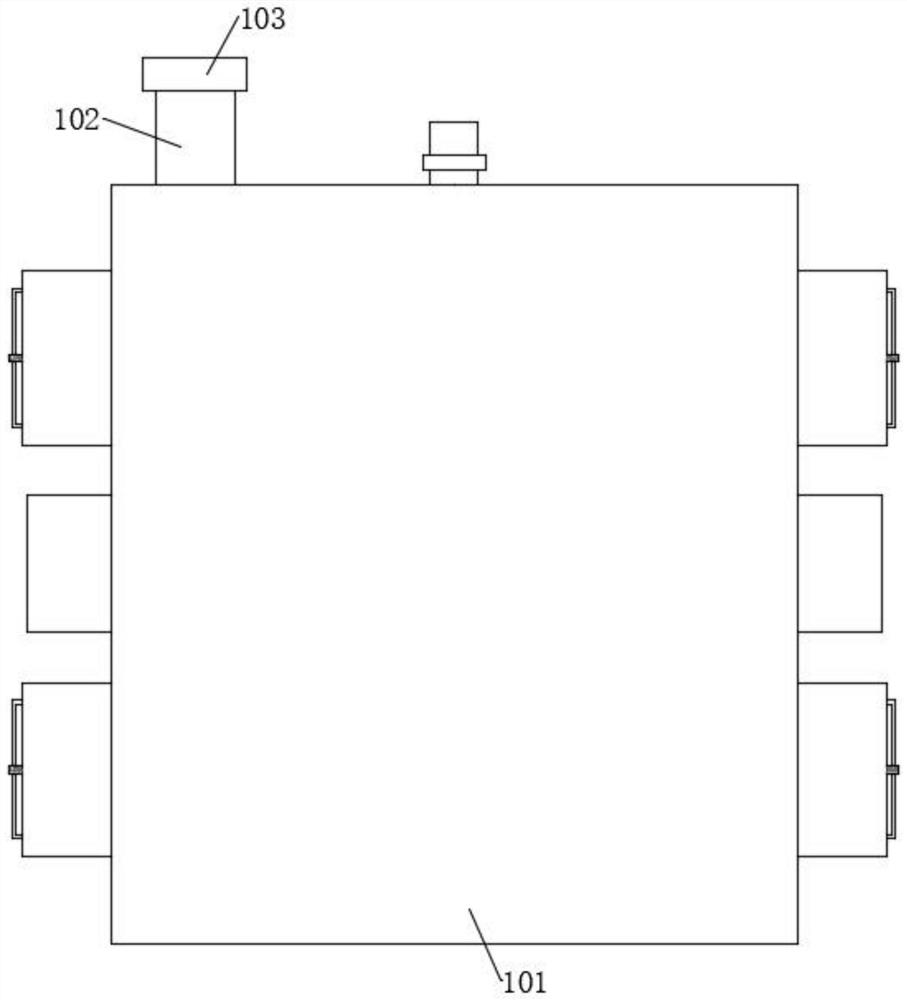

[0052] see Figure 2-3 and Figure 8 , the temperature-adjustable storage tank includes a storage tank 101...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com