Quality detection machine for high-grade metal inflatable lighter

An inflatable and lighter technology, applied in the testing of machines/structural components, instruments, combustion and ignition, etc., can solve the problems of low efficiency and easy injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

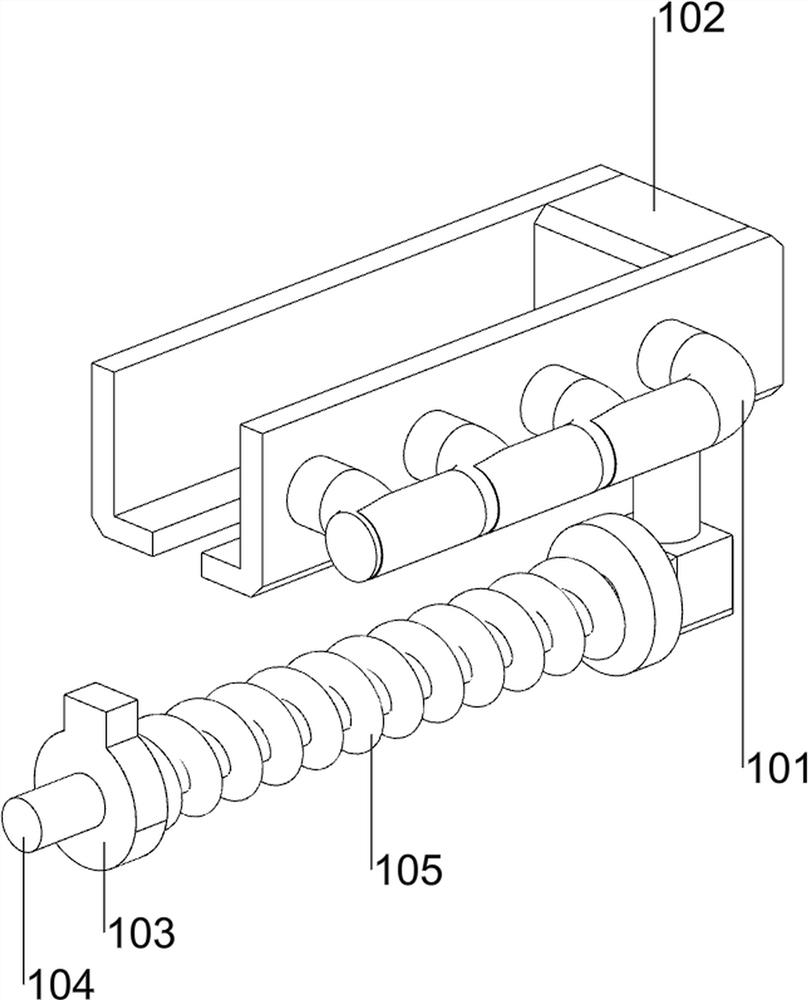

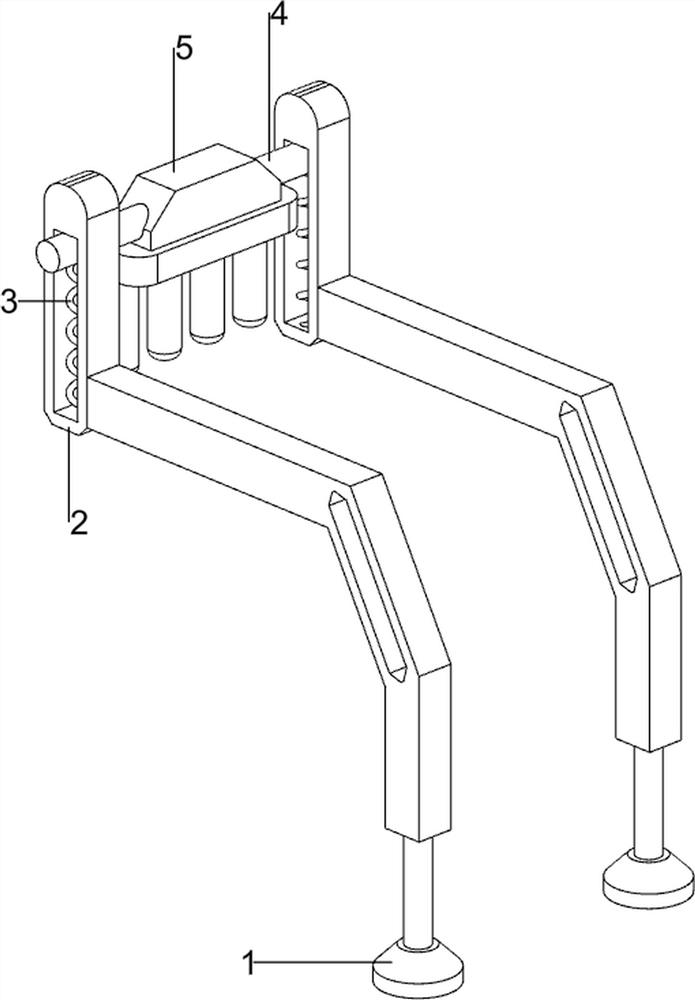

[0029] A metal high-grade inflatable lighter quality inspection machine, such as Figure 1-5 As shown, it includes a support foot 1, a first slide rail 2, a first spring 3, a connecting rod 4, a lower pressing rod 5, a placing mechanism 6 and a propulsion mechanism 7, and the support foot 1 is provided with a first slide rail 2, and the first A connecting rod 4 is slidably connected to the slide rail 2, and a first spring 3 is provided between the bottom of the connecting rod 4 and the first slide rail 2 on the same side, and a lower pressure rod 5 is connected between the connecting rod 4, and a supporting leg 1 The rear side is placed with a placement mechanism 6, and the placement mechanism 6 is provided with a propulsion mechanism 7.

[0030] The placement mechanism 6 includes a first support base 60, a first mounting plate 61, a second support base 62, a second mounting plate 63 and a baffle plate 64. Two first support bases 60 are placed on the rear side of the leg 1. Th...

Embodiment 2

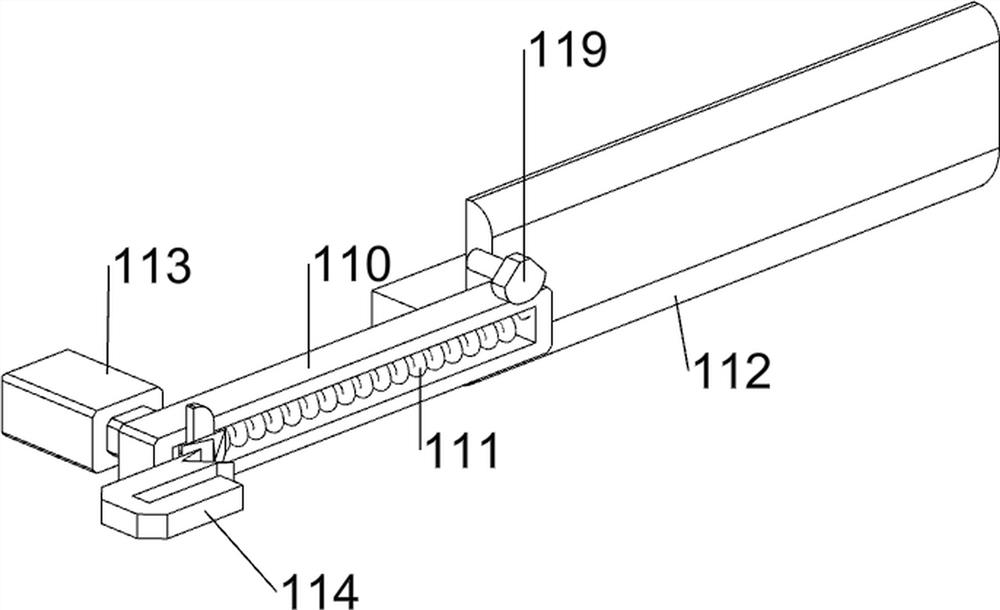

[0034] On the basis of Example 1, such as Figure 6-11 Shown, also comprise elevating mechanism 8, elevating mechanism 8 comprises advancing plate 80, connecting plate 81, advancing plate 82, connecting block 83, connecting column 84 and descending plate 85, hollow pipe 72 is provided with advancing plate 80, advances Plate 80 top, left and right sides are all provided with connecting plate 81, and connecting plate 81 tops are all provided with advance plate 82, and lower pressure bar 5 rear side is provided with connecting block 83, and connecting block 83 is provided with connecting column 84, and connecting column 84 left and right Both sides are provided with drop plate 85.

[0035] The hollow tube 72 moves forward to drive the forward plate 80, the connecting plate 81 and the forward plate 82 to move forward. When the forward plate 82 and the descending plate 85 are in contact, it drives the connecting block 83 and the connecting column 84 to move downward, thereby making...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com