Device for testing the aperture of porous material and testing method thereof

A technology for porous materials and testing devices, applied in suspension and porous material analysis, measuring devices, analyzing materials, etc., can solve the problems of troublesome process, high cost, deviation of detection area, etc., to ensure correctness, save costs, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object and technical solutions of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and embodiments:

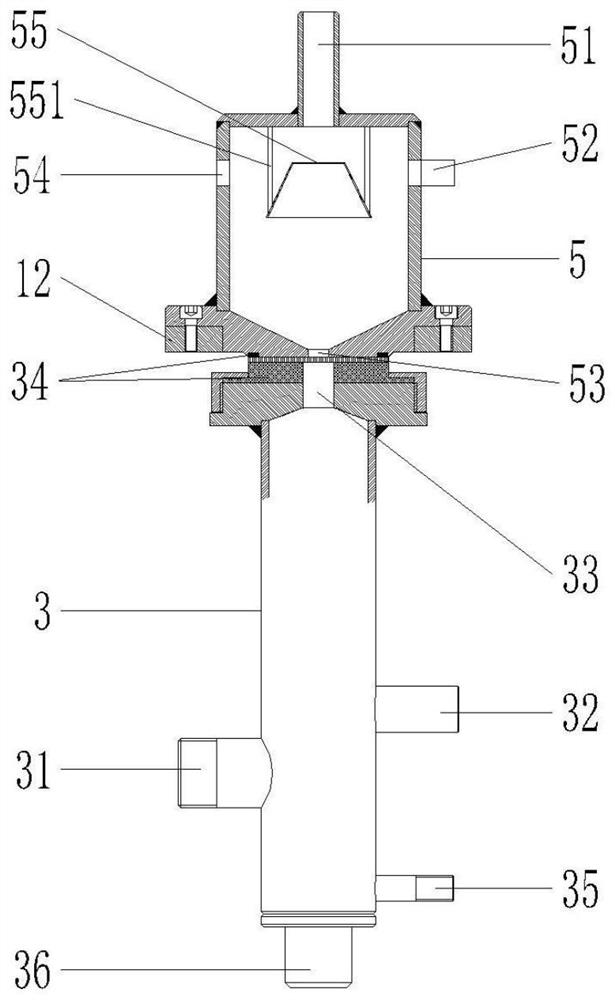

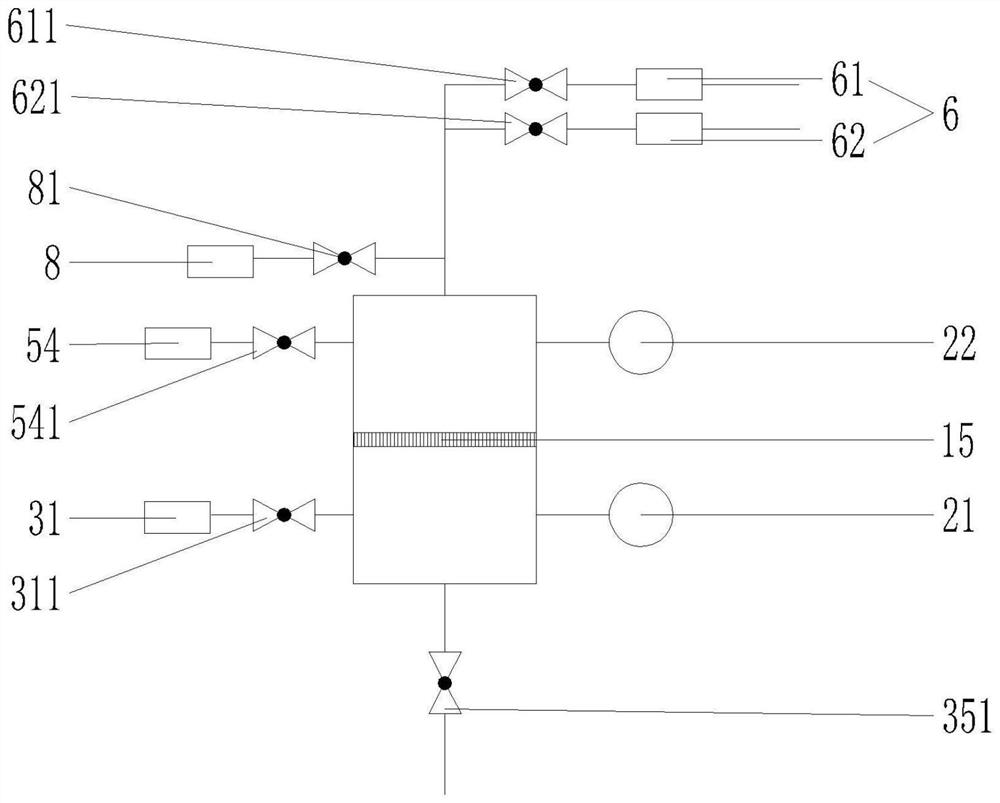

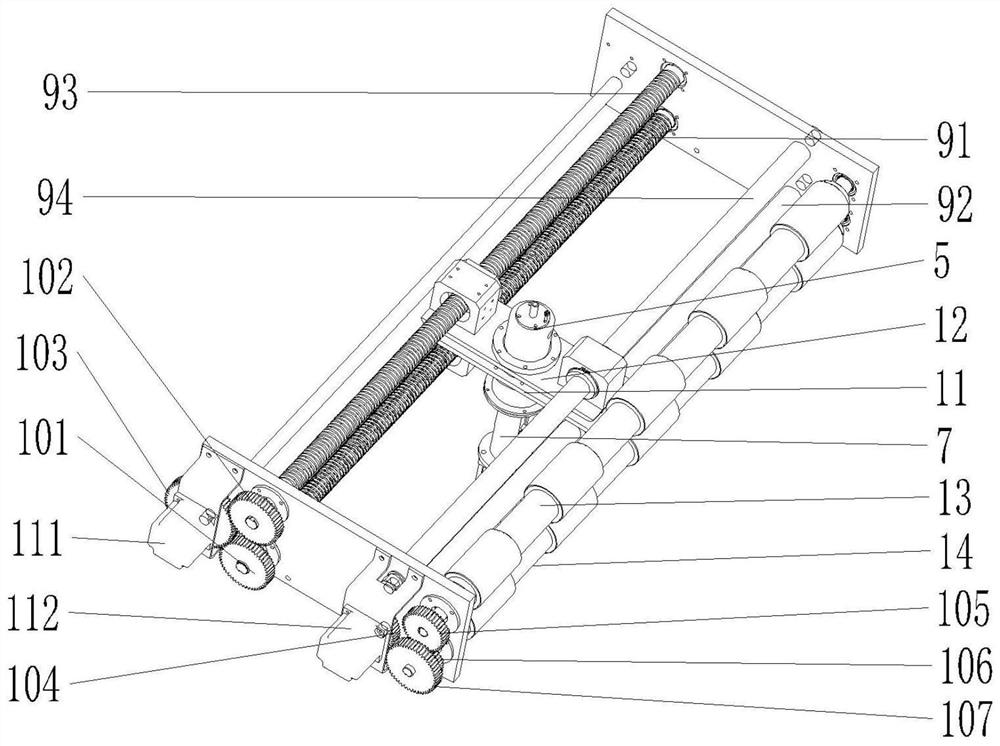

[0032] Such as Figure 1 ~ Figure 4 A porous material pore size testing device is shown, comprising: a lower chamber 3, the side of the lower chamber 3 is provided with an air inlet 31, a first pressure detection port 32, and the top of the lower chamber 3 is provided with a first The sample detection port 33; the air inlet 31 is externally connected with an air intake control device; the first pressure detection port 32 is externally connected with a first pressure sensor 21; the opening of the first sample detection port 33 faces upward; the upper cavity Chamber 5, installed and fixed above the lower chamber 3; the side of the upper chamber 5 is provided with a liquid filling port 54 and a second pressure detection port 52; the top of the upper chamber 5 is provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap