PC steel bar production cleaning equipment

A technology for cleaning equipment and steel rods, applied in lighting and heating equipment, cleaning methods and tools, cleaning methods using tools, etc., can solve problems affecting the quality of PC steel rod products, and achieve rapid soaking and rinsing, cleaning The effect of convenient process and convenient feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-7 The application is described in further detail.

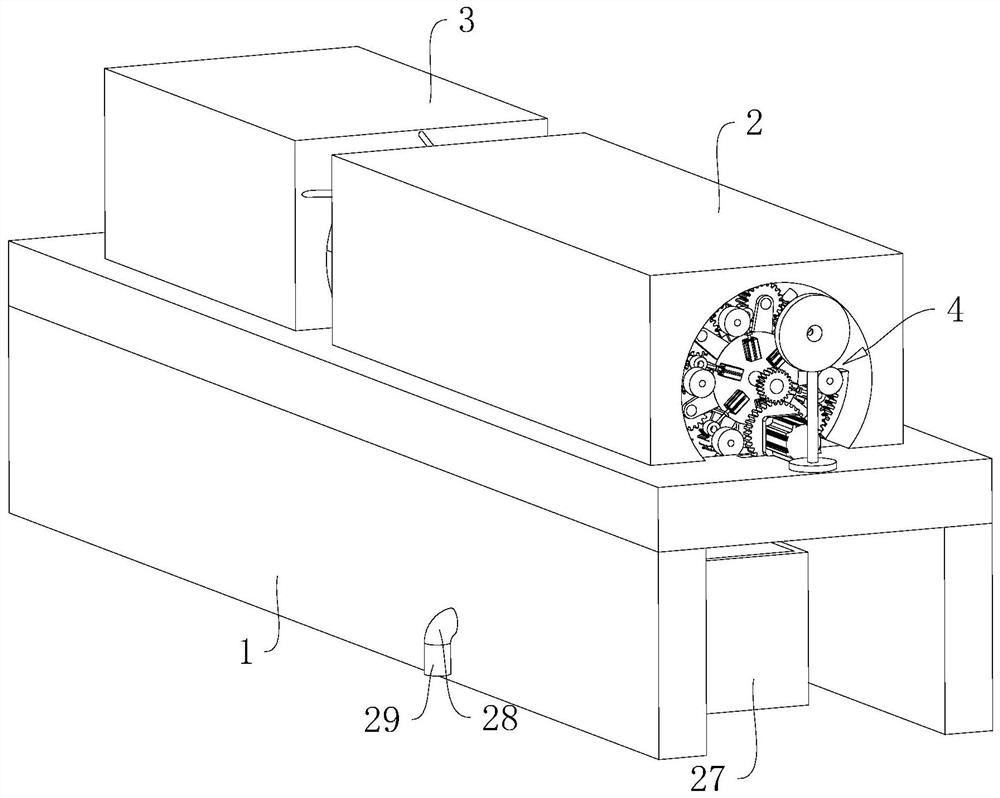

[0040] see figure 1 , a kind of PC steel bar production cleaning equipment, comprising a supporting frame supported on the ground, the upper end of the supporting frame 1 is welded with a cleaning frame 2 and a drying frame 3.

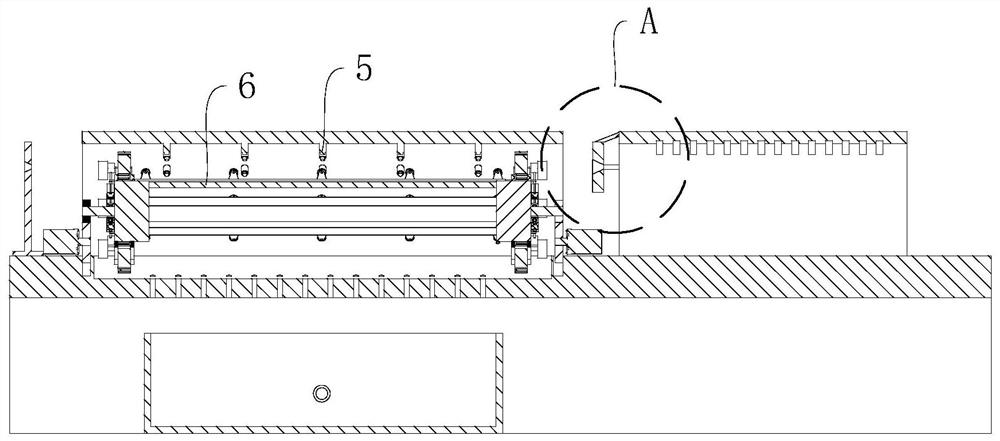

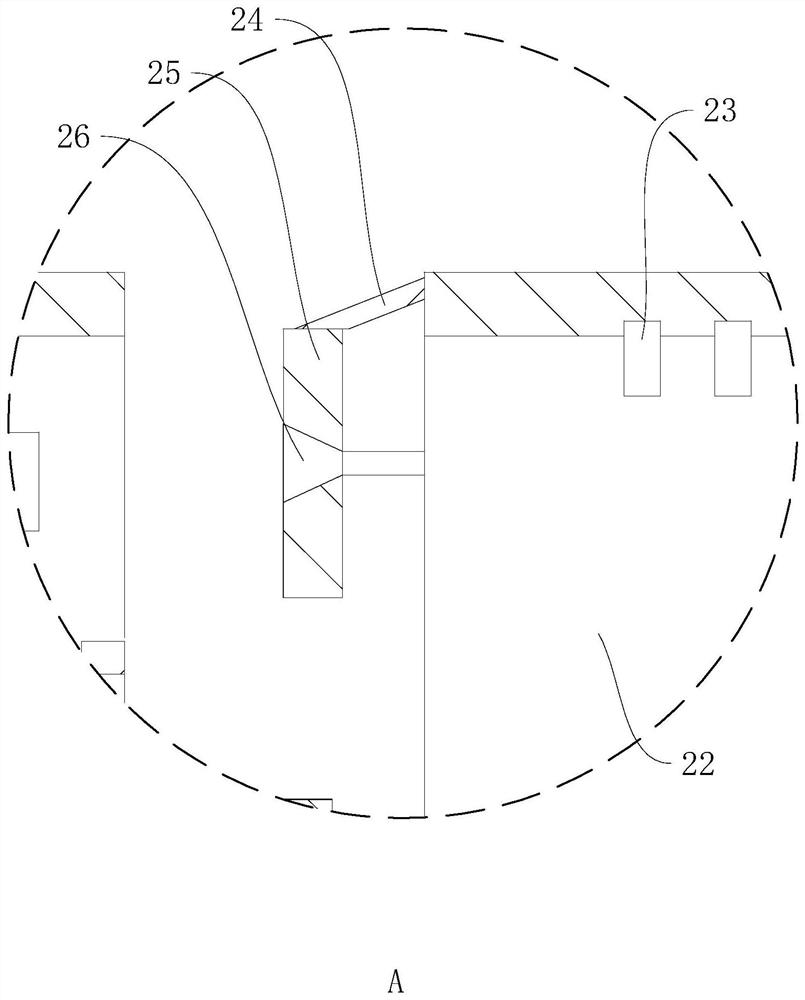

[0041] see figure 1 with figure 2 The middle part of the cleaning frame 2 is provided with a long cleaning chamber 4 that is cylindrical and communicated with both ends. The cleaning frame 2 is fixed with multiple groups of cleaning nozzles 5 by bolts on the inner wall of the cleaning long cavity 4, and the water outlets of the cleaning nozzles 5 point to the cleaning long cavity. The central axis of chamber 4.

[0042] see Figure 4 with Figure 5 , the cleaning frame 2 rotates in the cleaning long cavity 4 and is provided with a steel rod support frame 6, the motor is fixed in the support frame 1 by bolts, the output shaft of the motor penetrates int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com