Preparation of ultra-high damping manganese-copper alloy by directional solidification and preparation method thereof

A manganese-copper alloy, directional solidification technology, applied in the direction of improving energy efficiency, process efficiency, etc., can solve the problem of low damping performance, and achieve the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

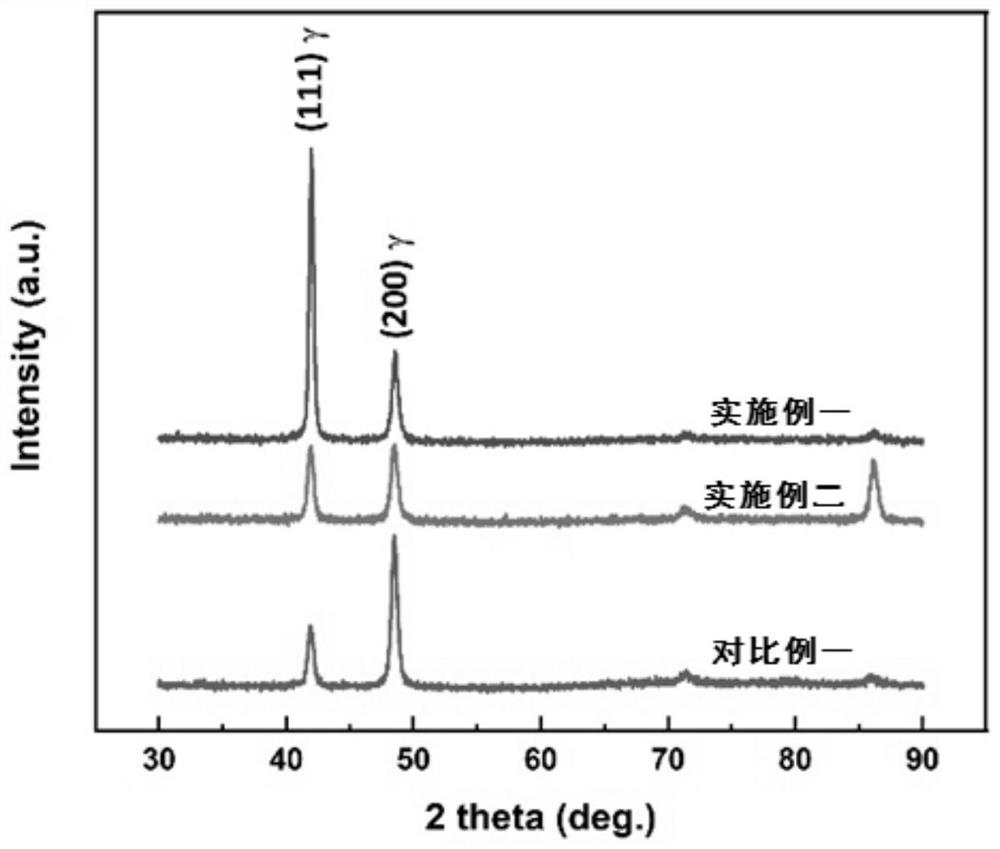

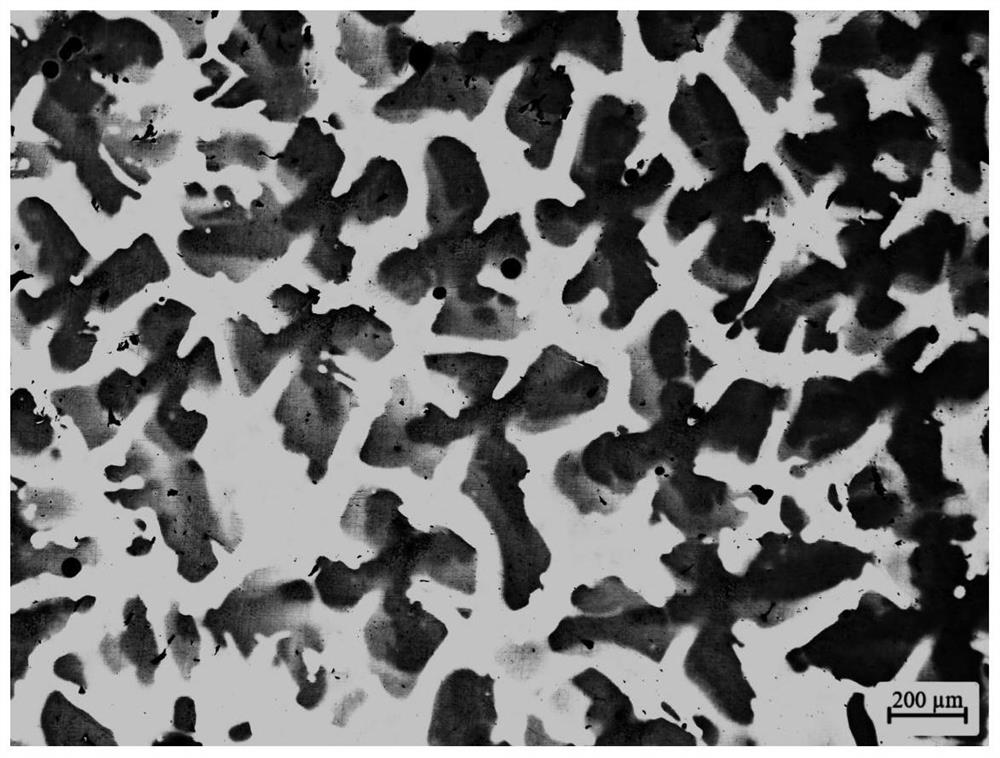

Embodiment 1

[0035] In this embodiment, a method for preparing ultra-high damping manganese-copper alloy by directional solidification includes the following steps:

[0036] a. Preparation of master alloy material:

[0037] The raw materials are prepared according to the weight percentage ratio of the components of the ultra-high damping manganese-copper alloy prepared as follows: Mn-20.0wt%Cu-5.0wt.%Ni-2.0wt.%Fe; put the initial raw materials in a crucible, set Melting in a vacuum induction melting furnace, introducing an argon protective atmosphere during the melting period, and controlling the induction heating to 1350 ° C for 20 minutes, so that the initial raw materials are fully melted, and then solidified to obtain a manganese-copper-based master alloy ingot material, which is used as Intermediate raw materials, spare;

[0038] b. Preparation of directionally solidified manganese-copper alloy:

[0039] b-1. Prepare the directional solidification furnace. The upper half of the furn...

Embodiment 2

[0044] This embodiment is basically the same as the first embodiment, and the special features are:

[0045] In this embodiment, a method for preparing ultra-high damping manganese-copper alloy by directional solidification includes the following steps:

[0046] a. Preparation of master alloy material:

[0047] The raw materials are prepared according to the weight percentage of the components of the ultra-high damping manganese-copper alloy prepared as follows: Mn-21.0wt.%Cu-4.0wt.%Ni-1.0wt.%Fe-0.05Ce%; In the crucible, place it in a vacuum induction melting furnace for melting. During the melting period, an argon protective atmosphere is introduced, and the induction heating is controlled to 1250 ° C for 50 minutes, so that the initial raw material is fully melted, and then solidified to obtain a manganese-copper-based master alloy. Ingot material, as an intermediate raw material, standby;

[0048] b. Preparation of directionally solidified manganese-copper alloy:

[0049...

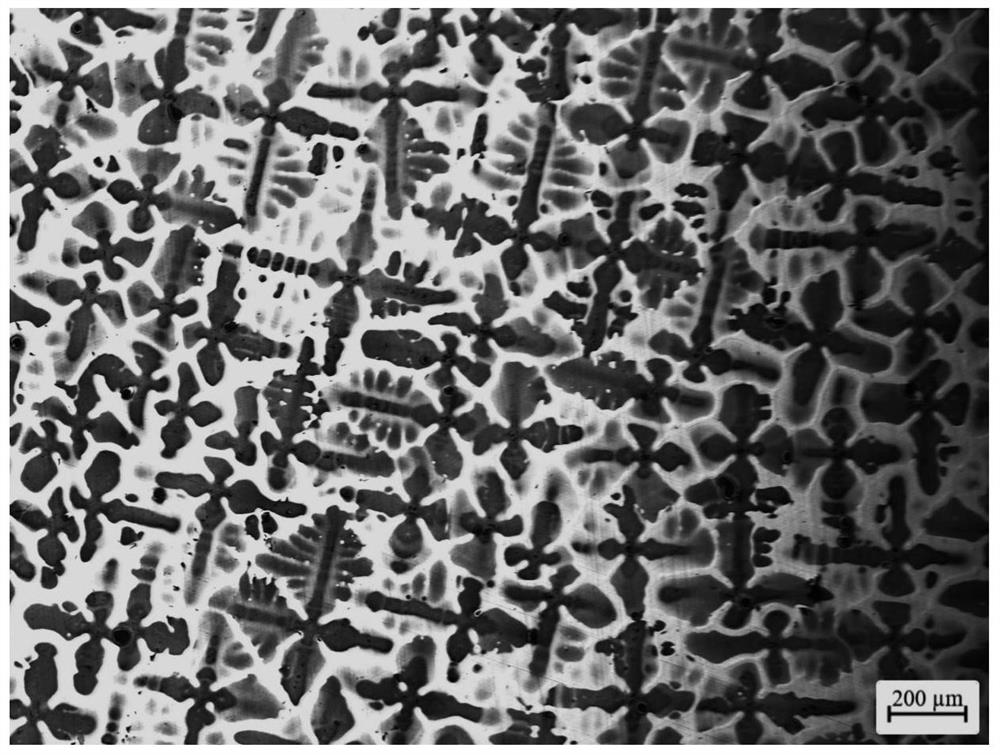

Embodiment 3

[0054] This embodiment is basically the same as the previous embodiment, and the special features are:

[0055] In this embodiment, a method for preparing ultra-high damping manganese-copper alloy by directional solidification includes the following steps:

[0056] a. Preparation of master alloy material:

[0057] The raw materials are prepared according to the weight percentage of the components of the ultra-high damping manganese-copper alloy prepared as follows: Mn-25.0wt% Cu; the initial raw materials are placed in a crucible and placed in a vacuum induction melting furnace for melting. During the melting period Introduce an argon protective atmosphere, and control the induction heating to 1300 ℃ for 50 minutes, so that the initial raw material is fully melted, and then solidified to obtain a manganese-copper-based master alloy ingot material, which is used as an intermediate raw material for standby;

[0058] b. Preparation of directionally solidified manganese-copper al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com