Direct-current brushless motor inner stator and production method thereof

A technology of DC brushless motor and production method, which is applied in the direction of manufacturing motor generators, manufacturing stator/rotor bodies, electrical components, etc., can solve the problem of effectively improving the operating efficiency of staff, insufficient preparation for installation and positioning, and lack of good assembly Sex and other issues, to achieve the effect of convenient assembly, ensuring stability and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

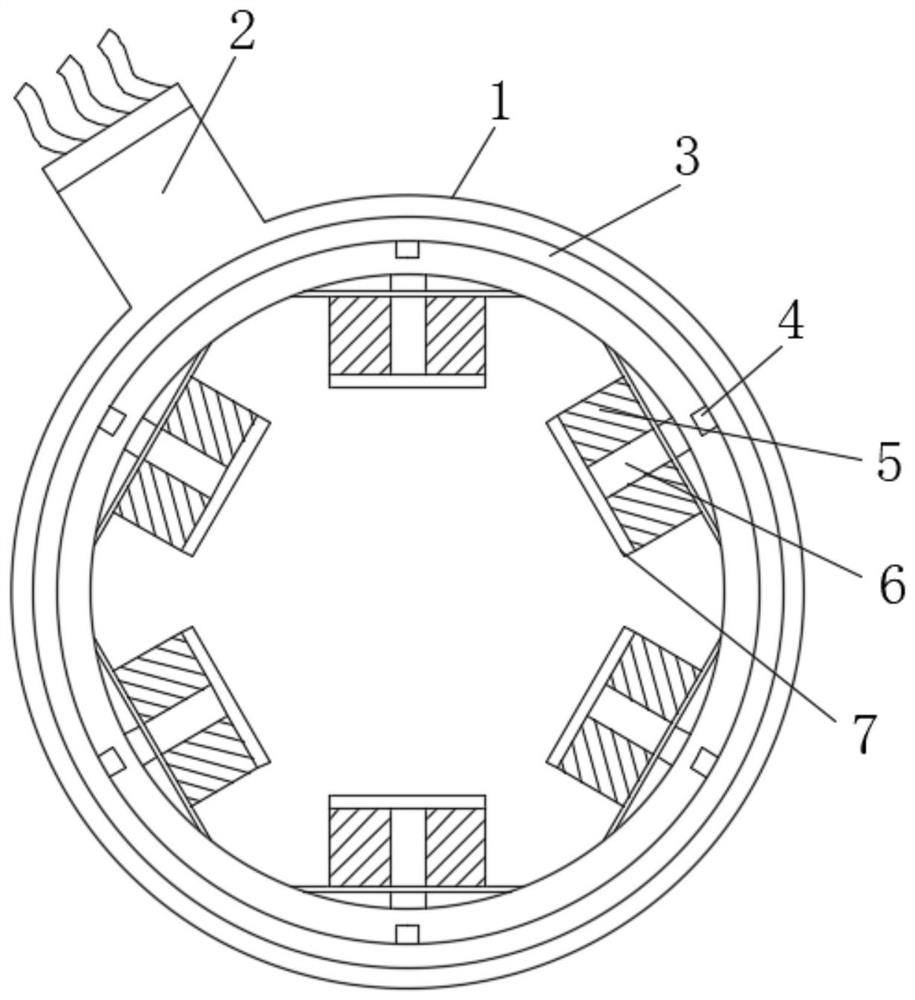

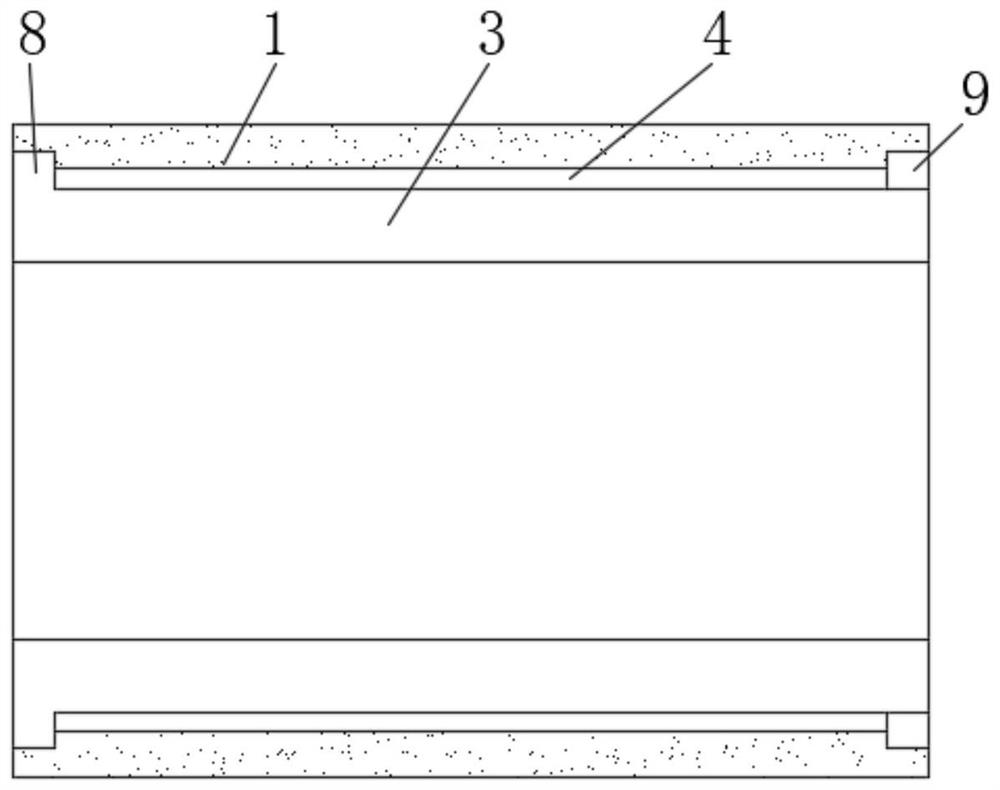

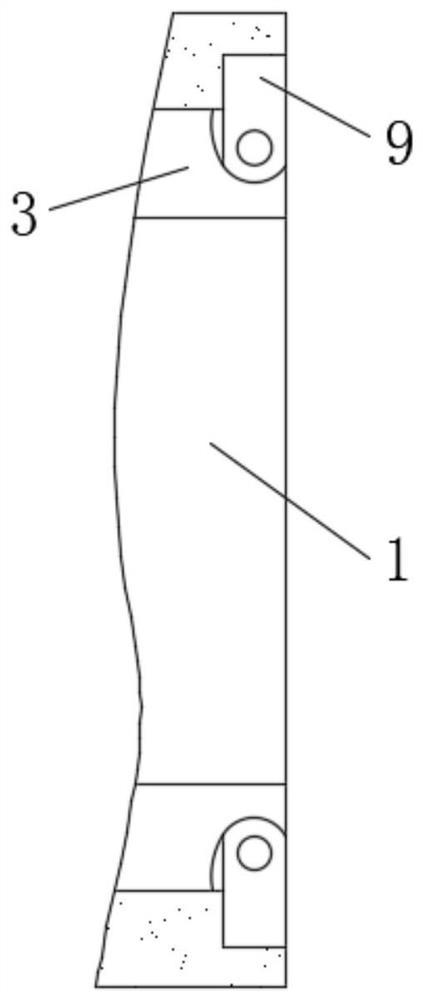

[0033] Embodiment 1: including a stator core 1, a connecting sleeve 2 is provided on one side of the stator core 1, an inner cylinder 3 is provided inside the stator core 1, and a clasp 8 is fixedly connected to one side of the inner cylinder 3, and the inner cylinder The other side of 3 is provided with a movable buckle 9, and an elastic hinge is arranged between the movable buckle 9 and the inner cylinder 3;

[0034] One side of the stator core 1 is provided with a groove, the buckle is arranged inside the groove, the inside of the inner cylinder 3 is fixedly connected with a rod body 6, the outside of the rod body 6 is wound with a coil winding 5, and one side of the rod body 6 is fixedly connected with a The yoke 7 and the inner wall of the stator core 1 are fixedly connected with the limit bar 4, and the limit bar 4 is arranged inside the inner cylinder 3;

[0035] The inside of the connecting sleeve 2 is provided with a connecting cylinder 11, a side of the connecting cy...

Embodiment 2

[0045]Embodiment 2: It includes a stator core 1, a connecting sleeve 2 is arranged on one side of the stator core 1, an inner cylinder 3 is arranged inside the stator core 1, and a clasp 8 is fixedly connected to one side of the inner cylinder 3, and the inner cylinder The other side of 3 is provided with a movable buckle 9, and an elastic hinge is arranged between the movable buckle 9 and the inner cylinder 3;

[0046] One side of the stator core 1 is provided with a groove, the buckle is arranged inside the groove, the inside of the inner cylinder 3 is fixedly connected with a rod body 6, the outside of the rod body 6 is wound with a coil winding 5, and one side of the rod body 6 is fixedly connected with a The yoke 7 and the inner wall of the stator core 1 are fixedly connected with the limit bar 4, and the limit bar 4 is arranged inside the inner cylinder 3;

[0047] The inside of the connecting sleeve 2 is provided with a connecting cylinder 11, a side of the connecting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com