Preparation method of middle frame and electronic equipment middle frame

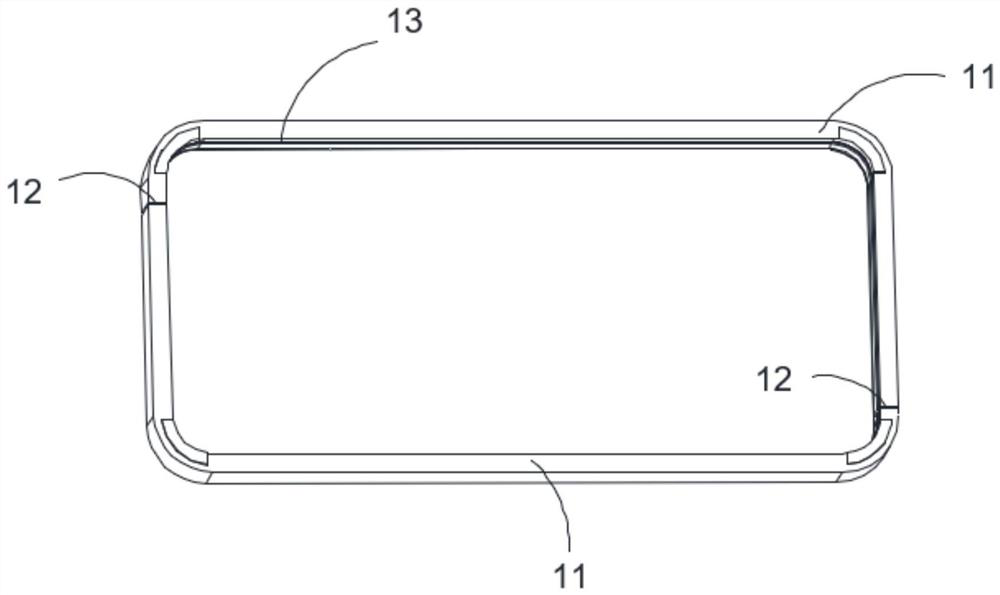

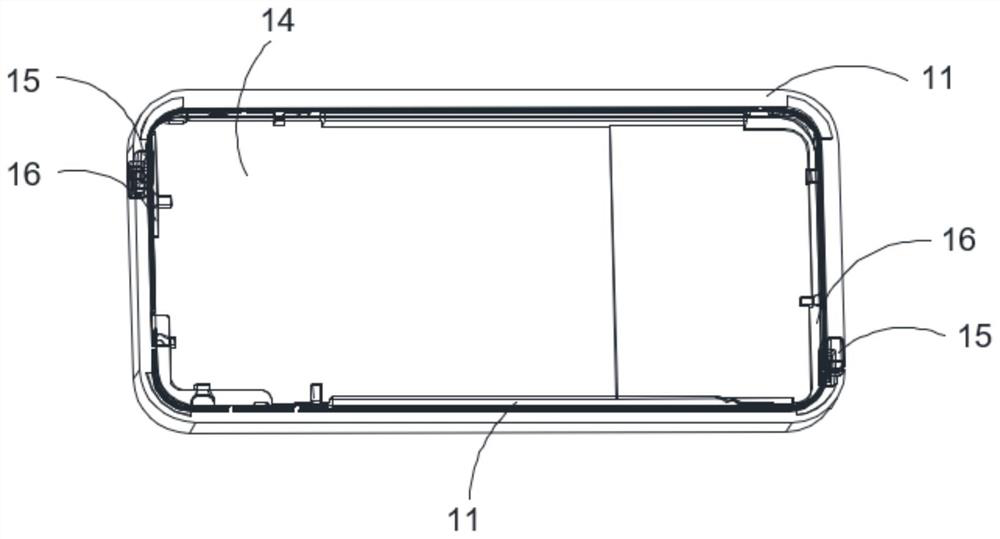

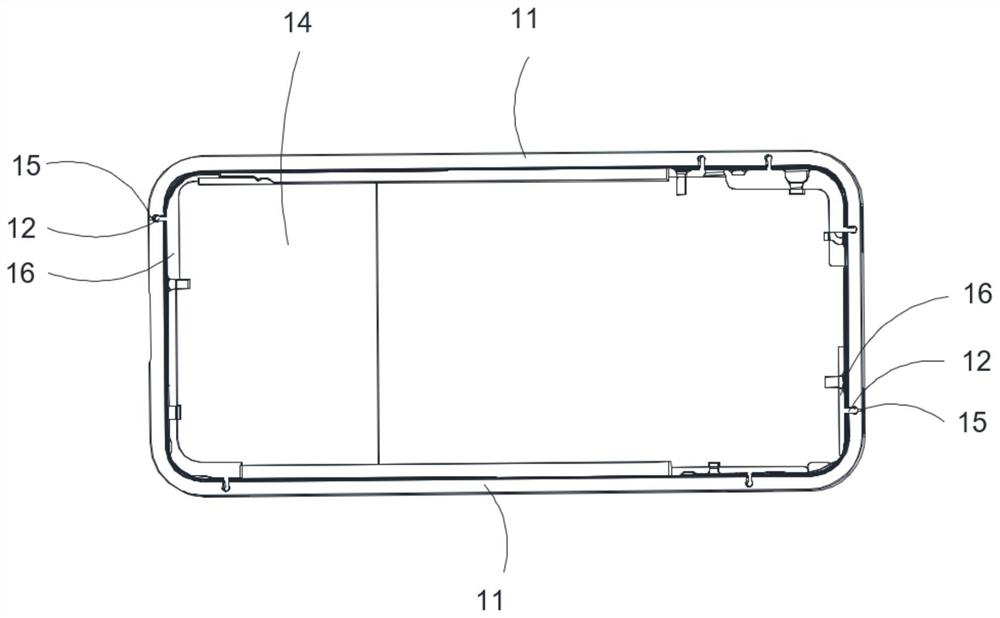

A technology for electronic equipment and frames, which is applied to electrical equipment shells/cabinets/drawers, welding equipment, laser welding equipment, etc., and can solve the problem of connecting aluminum strips 11 on both sides of the weakened gap 12, aluminum strips 11 around the weakened gap 12 and the middle plate 14 Problems such as connection and frame breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Such as Figure 4 to Figure 8 as shown, Figure 4 It is a schematic flowchart of a method for preparing a middle frame antenna according to an embodiment of the present invention; Figure 5-Figure 8 for correspondence Figure 4 In the schematic diagram of the structure during the processing of the middle frame in the flow chart, the preparation method of the middle frame antenna specifically includes the following steps:

[0046] Such as figure 1 As shown, the manufacturing method of the middle frame module includes steps:

[0047] Step S100 , providing several aluminum strips, and arranging the several aluminum strips at intervals to form a rectangular frame with gaps.

[0048] Wherein, the quantity and shape of the aluminum strips can be adjusted accordingly according to the position and quantity of the slit 23, for example Figure 5-Figure 8 In the embodiment of the present invention, two slits 23 are provided, and the two slits 23 are arranged symmetrically to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com